Optical fiber contact member and optical fiber connector using same

An optical fiber connector and optical fiber contact technology, which is applied in the field of optical fiber communication to achieve the effects of increasing the density of contacts, reducing the overall size, and increasing the amount of data transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means and technical effects adopted by the present invention, the present invention will be described in detail below in conjunction with the examples.

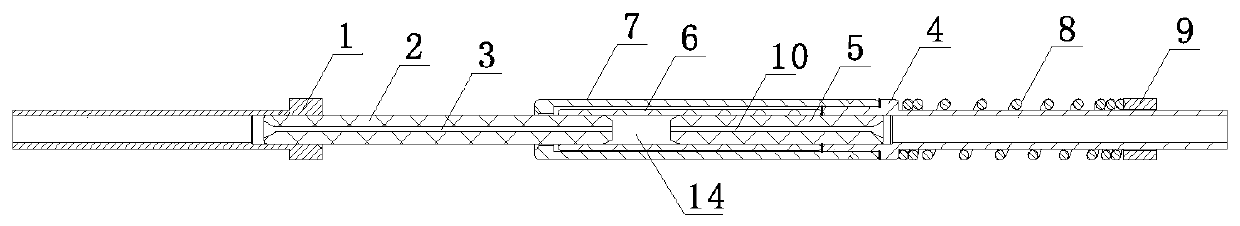

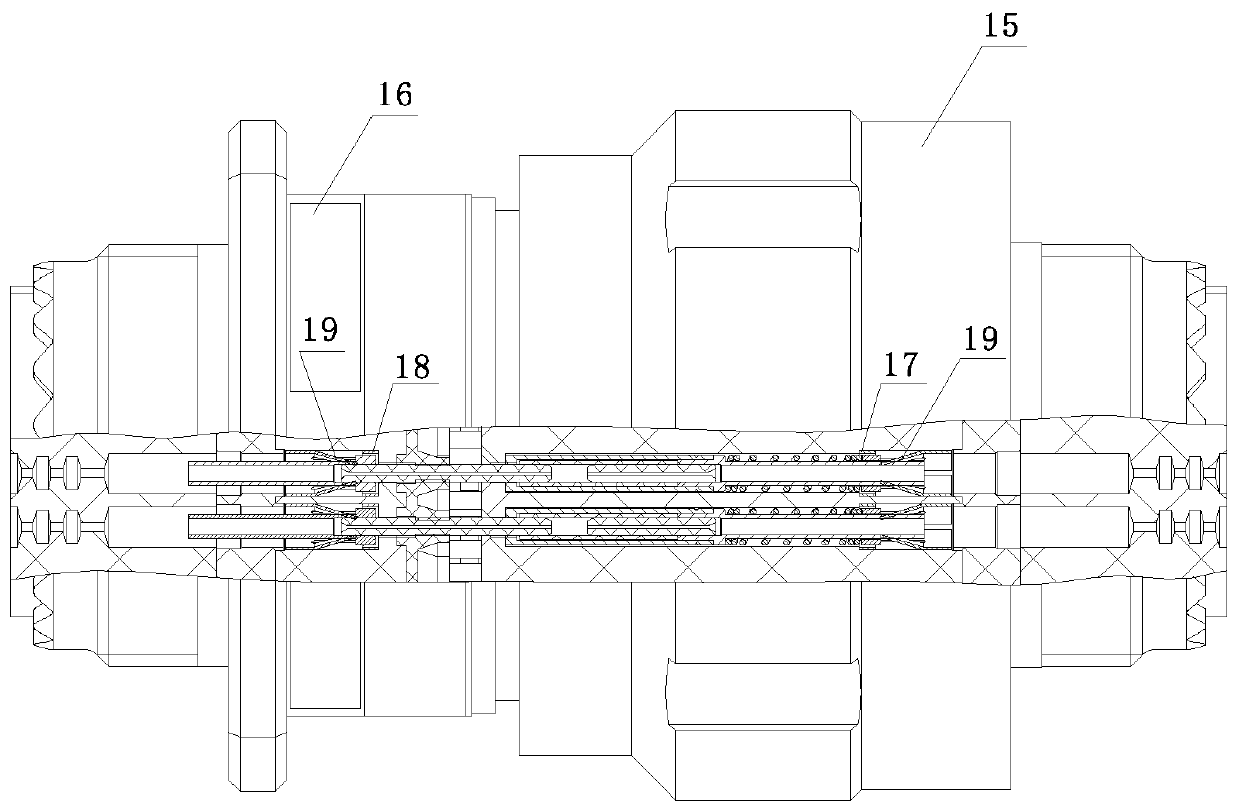

[0032] The present invention proposes a 22D optical fiber contact with a smaller volume than the current No. 20 optical fiber contact. A pair of 22D optical fiber contacts includes a pin contact and a socket contact. The pin contacts include a pin flange 1 1. Ceramic ferrule I2, the ceramic ferrule I is fixed with an optical fiber I3, one end of the ceramic ferrule I is fixed in the ferrule flange, and the other end is used to insert the jack contact. Jack contacts include jack flange 4, ceramic pin II 5, ceramic sleeve 6, metal sleeve 7, spring 8 and rear sleeve 9, and optical fiber II 10 is fixed inside ceramic pin II; jack flange includes flange Plate front diameter section 11, flange boss 12 and flange rear diameter section 13, the front diameter section, boss and rear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com