Bonding assembly performance evaluation method

A bonding and adhesive technology, applied in measurement devices, mechanical devices, instruments, etc., can solve the problems of high-precision simulation analysis model difficulty, difficult application of traditional evaluation methods, etc., to achieve accurate calculation results and avoid errors , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

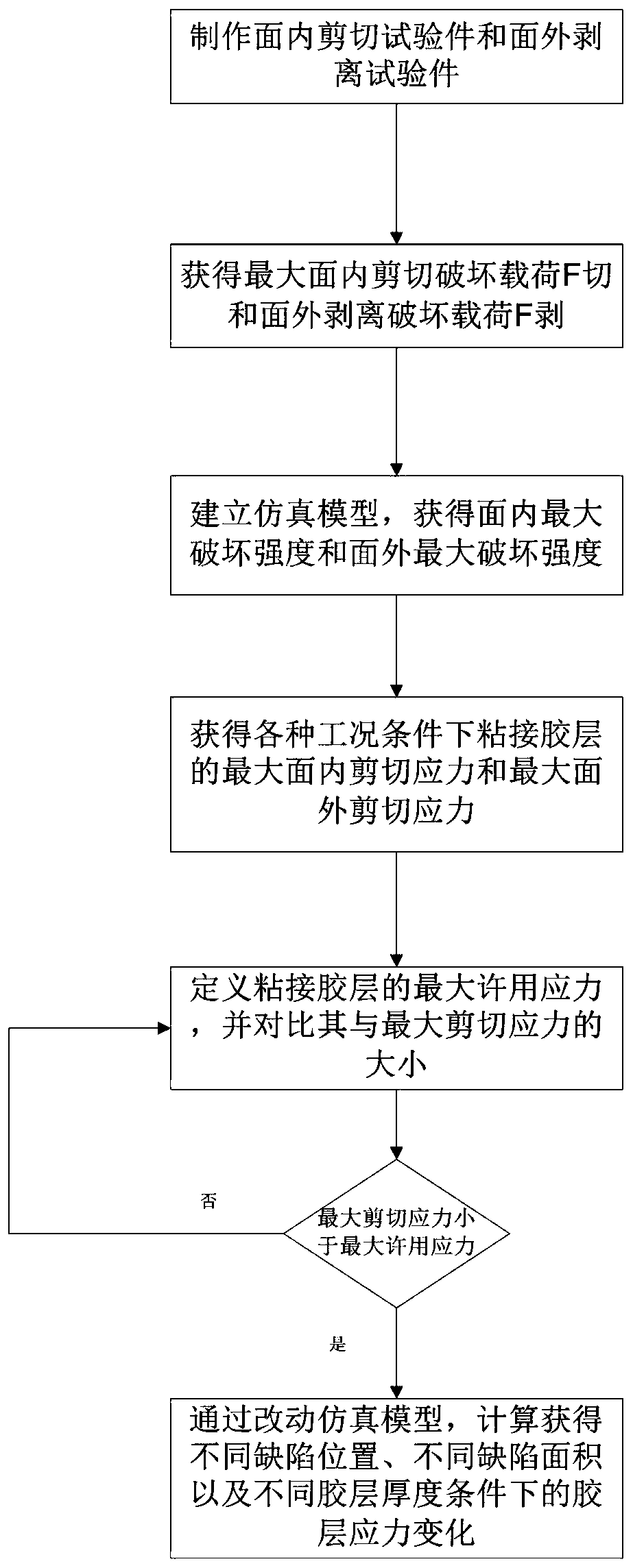

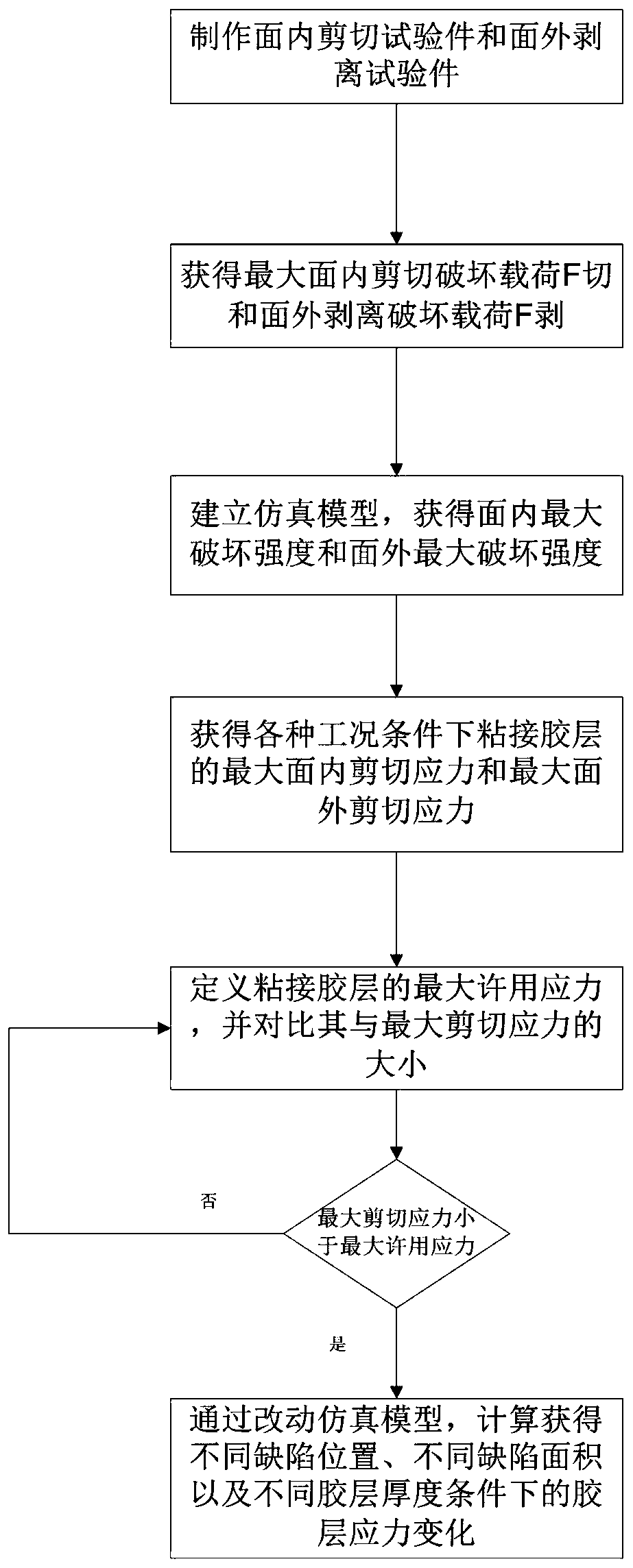

[0022] Such as figure 1 As shown, a bonding scheme evaluation method, the steps are as follows,

[0023] In the first step, ten in-plane shear test pieces and ten out-of-plane peel test pieces are produced.

[0024] In the second step, the in-plane shear test and the out-of-plane peel test are respectively carried out for the peeling test pieces obtained in the first step, and the maximum in-plane shear failure load F of each test piece is obtained 切i and out-of-plane peeling failure load F 剥i , i=1, 2, 3...10, choose the largest F 切、 f 剥 is the maximum in-plane shear failure load and out-of-plane peel failure load of the test piece.

[0025] The third step is to establish the same simulation calculation model as the test state, and use the maximum in-plane shear failure load F 切 and out-of-plane peeling failure load F 剥 As input, the in-plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com