Copper bar tensile force testing machine

A technology of tensile testing machine and tensile device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of troublesome fixing of copper bars, inaccurate values, simple structure, etc., and achieve convenient fixing , Tensile test is accurate, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

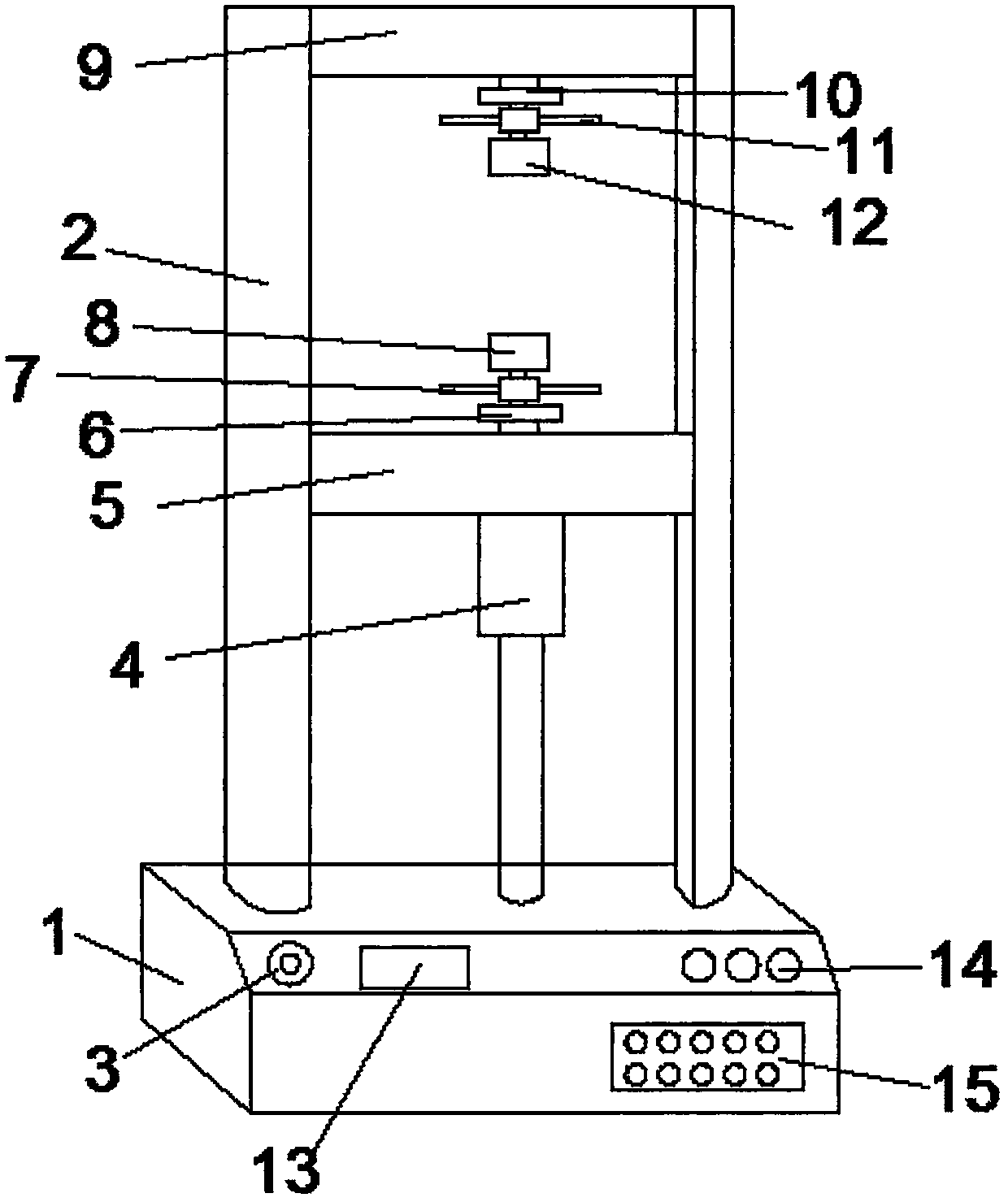

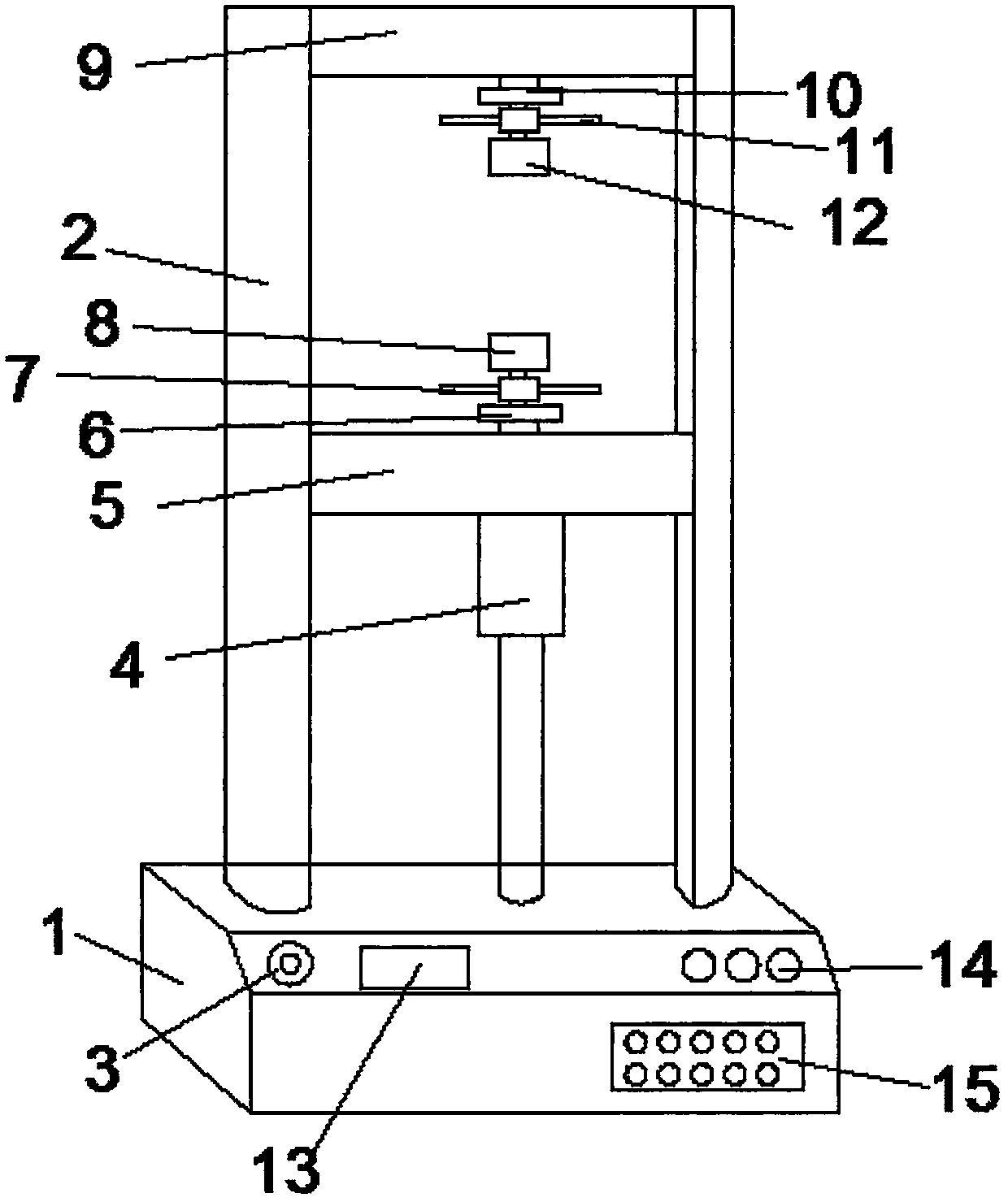

[0014] Such as figure 1 As shown, the present invention provides a copper bar tensile testing machine, comprising a base 1, a pillar, a moving rod 5 and a beam 9, characterized in that a pillar 2 is installed above the base 1, and a moving rod is installed on the pillar 2 5. A control switch 3 is installed on the upper surface of the base 1, a tensioner 4 is installed under the moving rod 5, a lower connecting rod 6 is installed above the moving rod 5, and a lower adjusting rod 7 is installed above the lower connecting rod 6 , the lower fixing frame 8 is installed above the lower adjusting rod 7, the upper part of the pillar 2 is connected with the crossbeam 9, the upper connecting rod 10 and the upper adjusting rod 11 are installed below the crossbeam 9, and the lower part of the upper adjusting rod 11 is installed with On the fixed frame 12, control buttons 15, a display screen 13 and a running indicator light 14 are installed on the upper surface of the base 1.

[0015] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com