A lifting chain tension testing machine

A testing machine and chain technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of large floor space and long length, and achieve noise reduction, simple structure and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

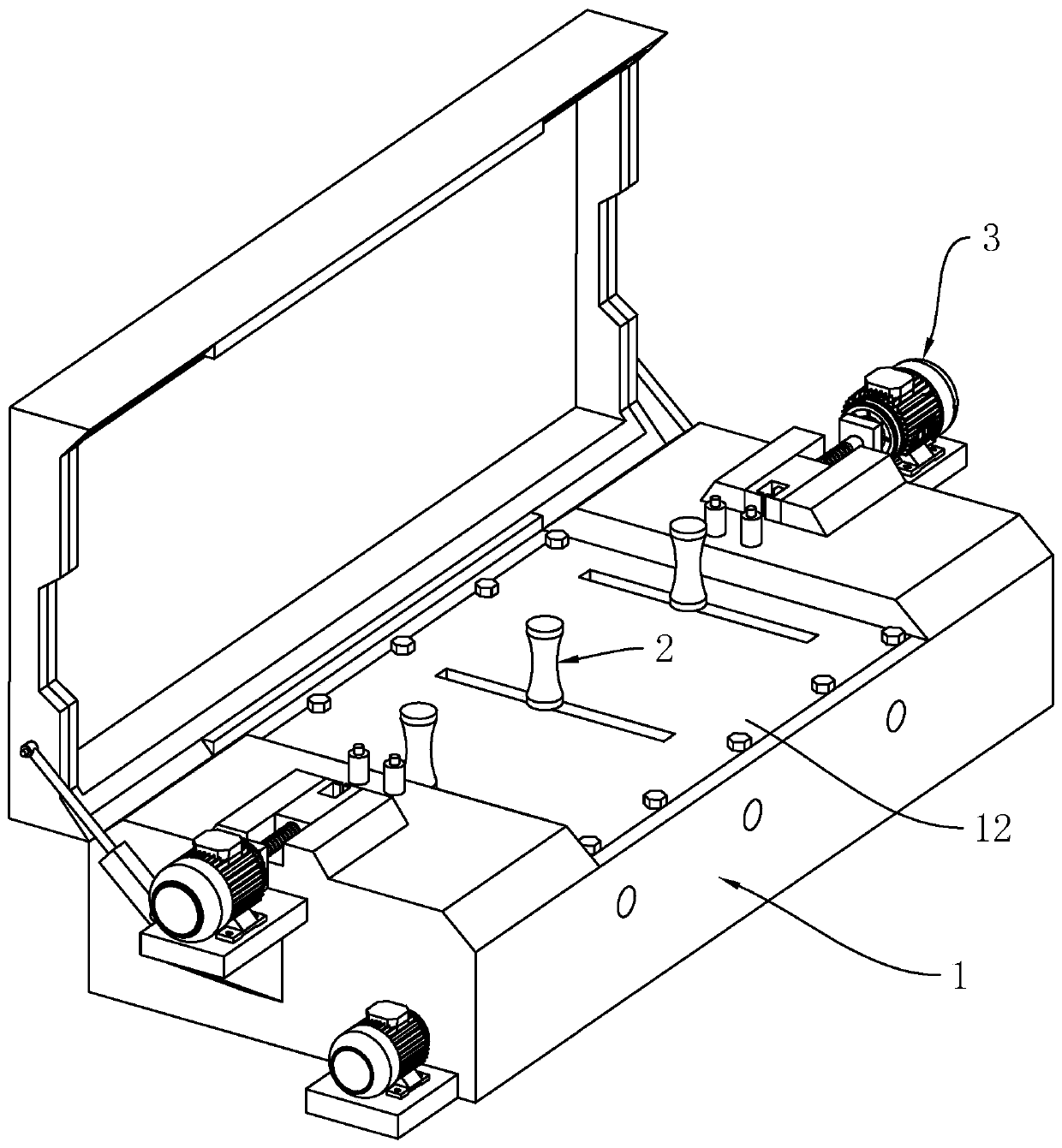

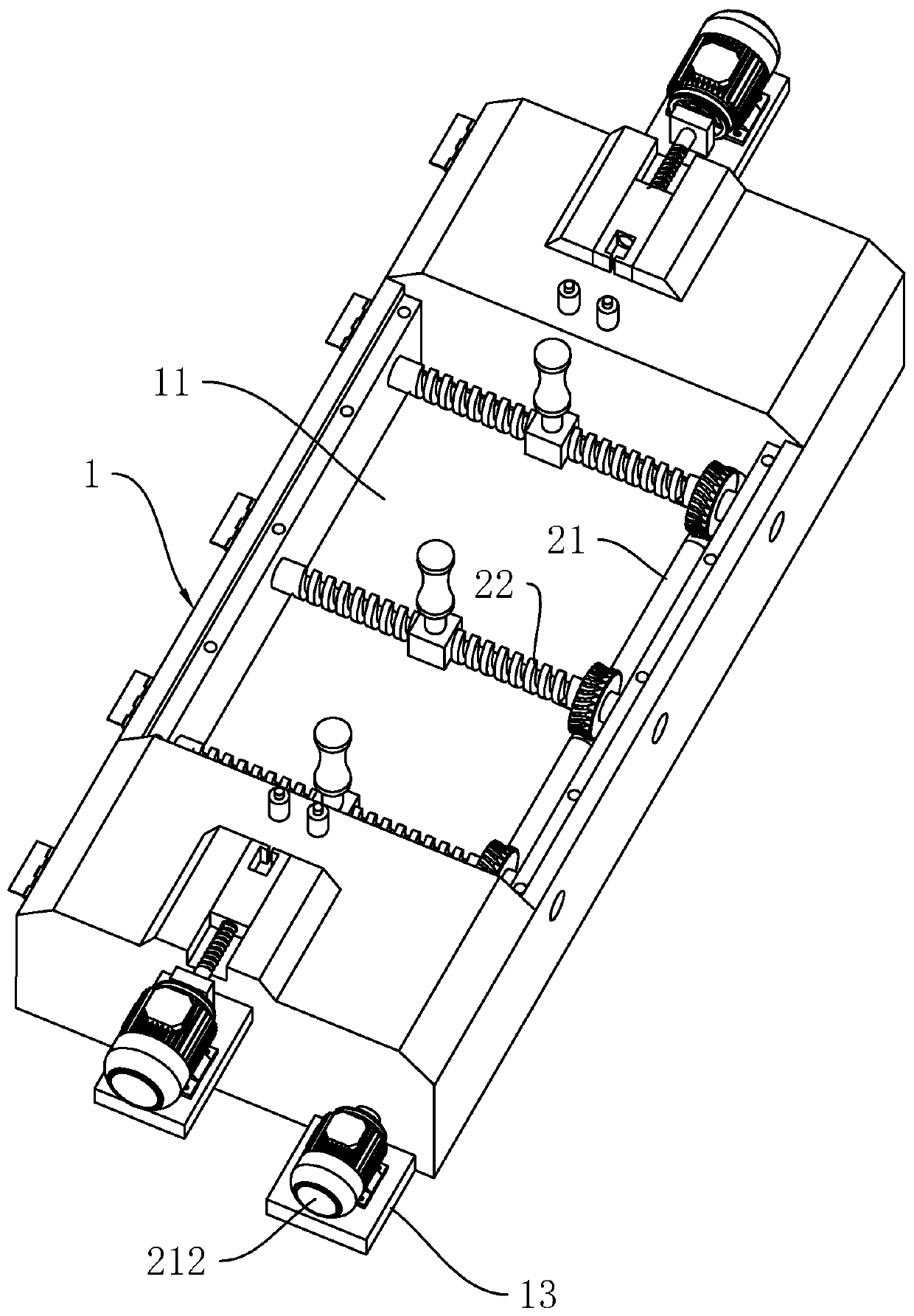

[0037] Embodiment: a kind of lifting chain tension detection machine, combines figure 1 and figure 2 , including a frame body 1, a distance adjustment component 2 and a stretching component 3, a cavity 11 is opened inside the frame body 1, a cover plate 12 is horizontally arranged above the cavity 11, and the cover plate 12 is bolted to the frame body 1 surface.

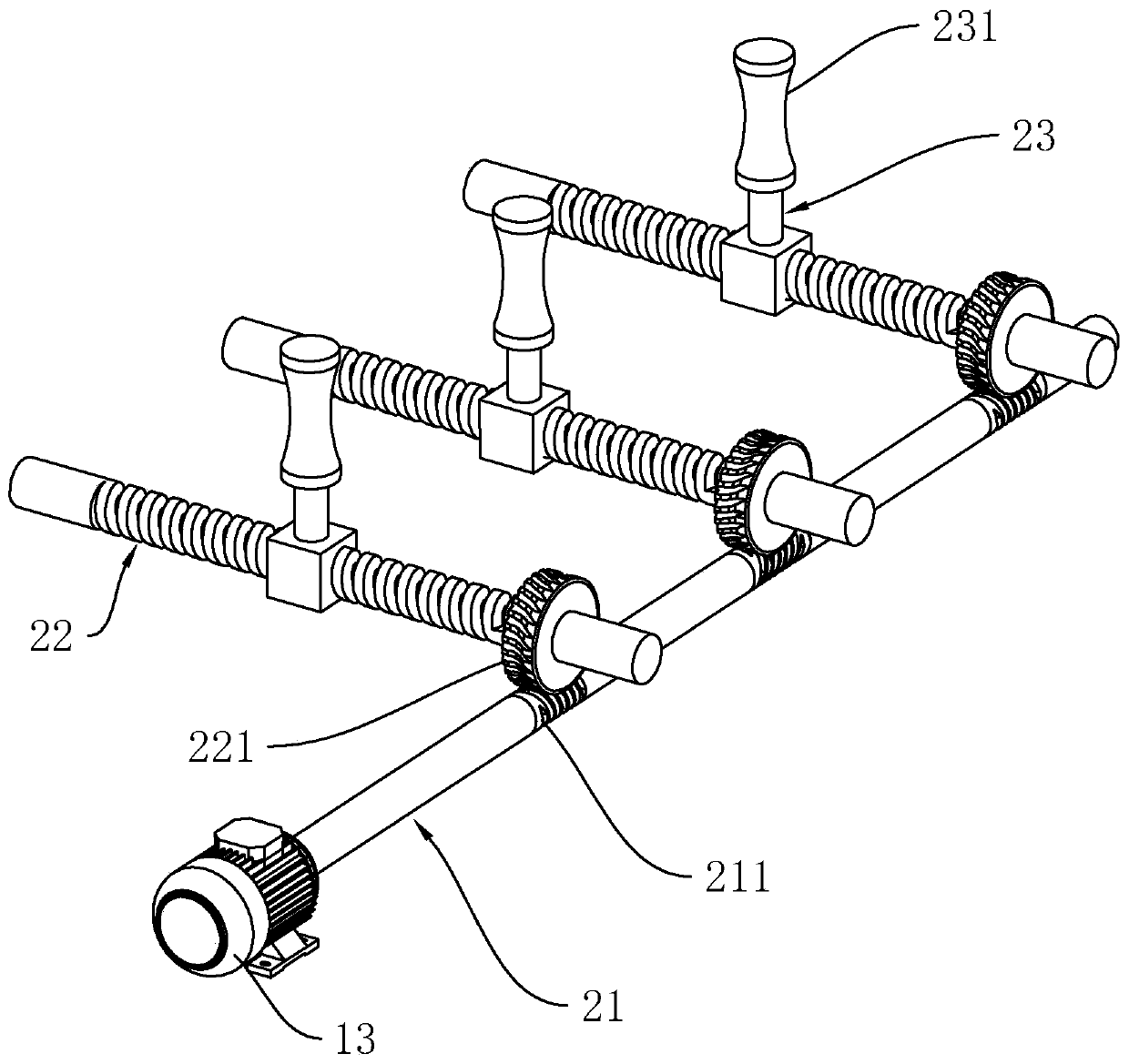

[0038] combine figure 2 and image 3 The distance adjusting assembly 2 is arranged in the cavity 11, and the distance adjusting assembly 2 includes adjusting rods 21 whose two ends are rotatably connected to the two ends of the frame body 1 in the length direction and a plurality of two ends respectively rotatably connected to the two ends of the frame body 1 in the width direction. The screw 22 on the side, the axial direction of the adjusting rod 21 and the axial directions of the plurality of leading screws 22 are respectively perpendicular to each other, and the positions corresponding to the plurality of le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com