Industrial pulverized coal boiler burner with secondary air axial blade angle capable of being adjusted

A blade angle, pulverized coal boiler technology, applied in the direction of burners burning powder fuel, burners, combustion methods, etc., can solve the problems of less than 70% average efficiency, high emission of dust pollutants, poor ignition stability, etc., and achieve structural Effects of compactness, emission reduction, and stability maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

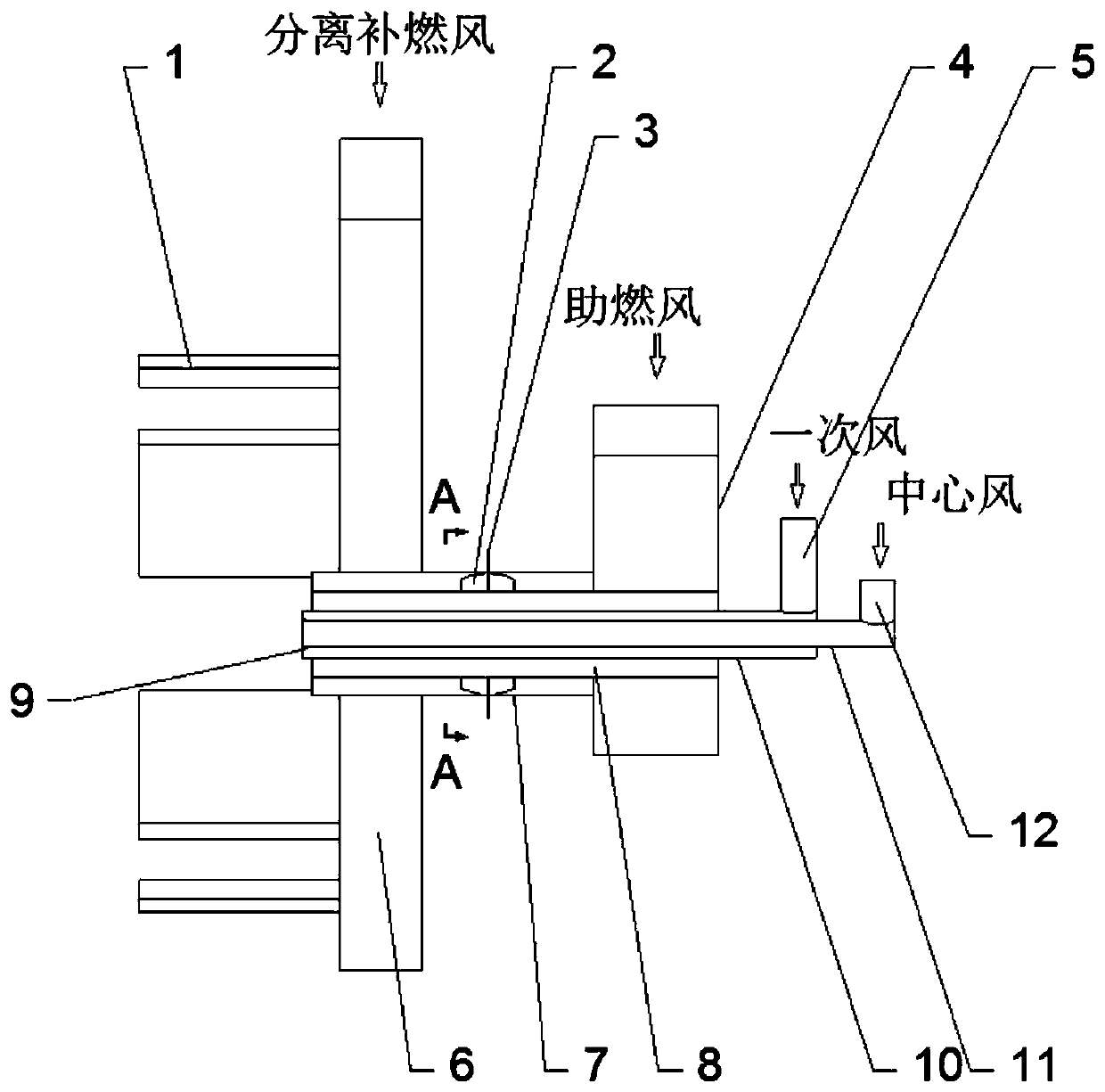

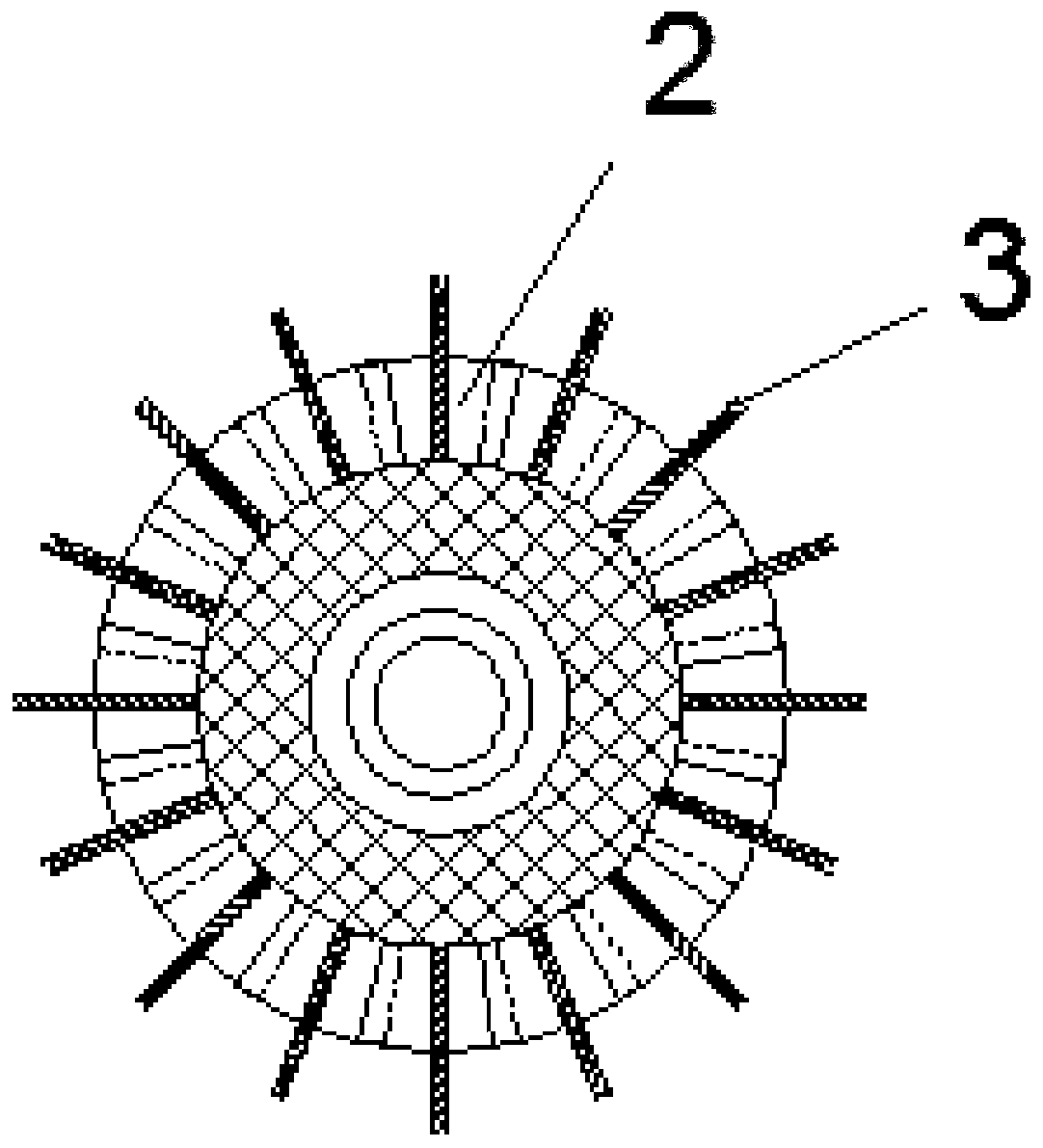

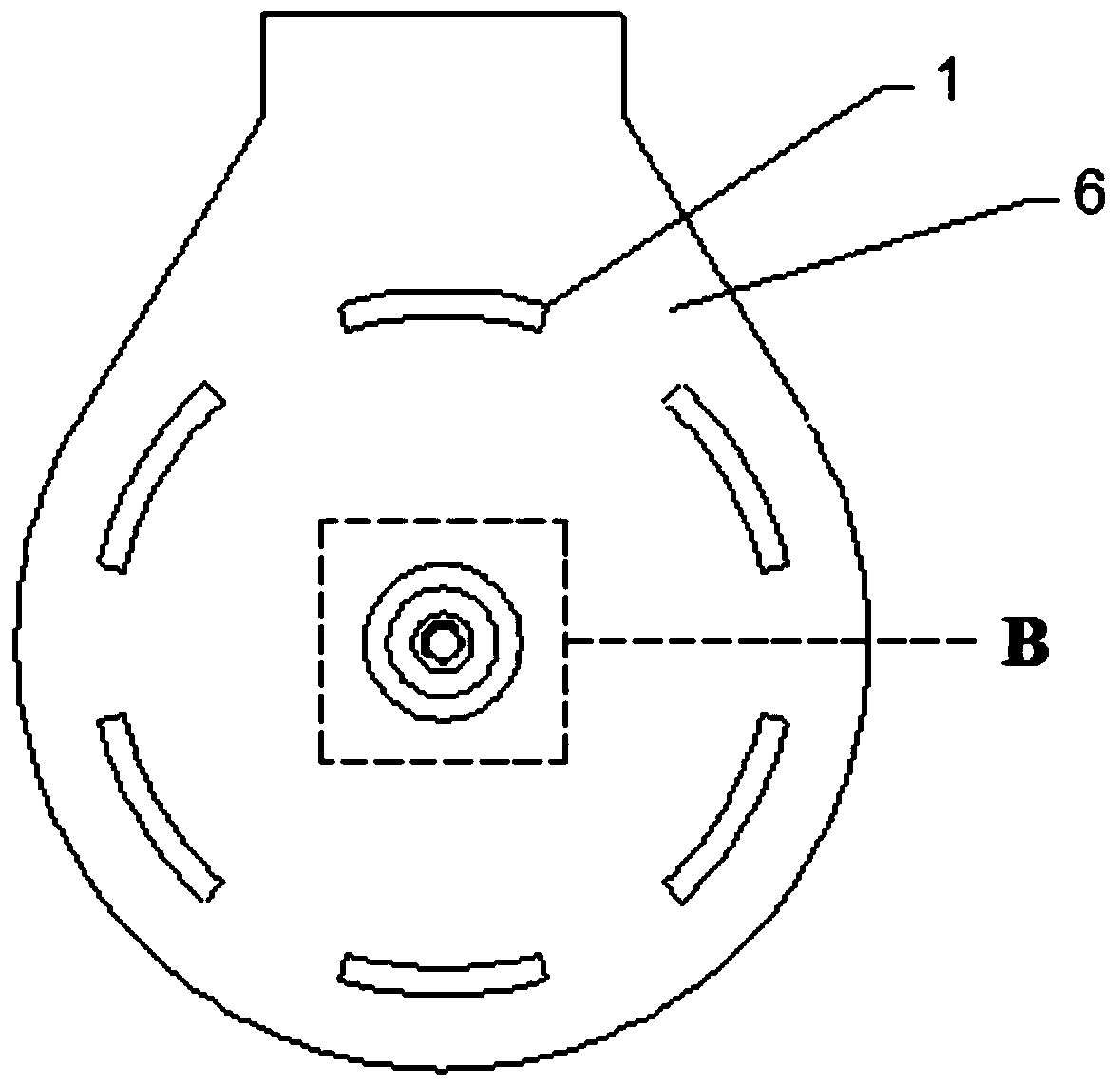

[0031] see figure 1 , image 3and Figure 4 , a low-nitrogen burner for a coal-fired industrial pulverized coal boiler according to an embodiment of the present invention includes a pre-combustion chamber and a combustion-supporting air sleeve 7 connected to the pre-combustion chamber.

[0032] The pre-combustion chamber housing of the present invention has the same number of separated supplementary combustion air nozzles at the corresponding position of the separated supplementary combustion air ring as the separated supplementary combustion air ring, and the separated supplementary combustion air is sent into the furnace in a straight-line manner to elongate the flame and prevent flame brushing. wall. Strengthen the disturbance in the late stage of the furnace, and strengthen the mixing in the late stage of flame combustion.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com