Environmental protection composite pipe

A composite pipe, environmental protection technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of wasting manpower, water loss, easy clogging of filters, etc., and achieve the effect of reducing clogging problems, reasonable structure design, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

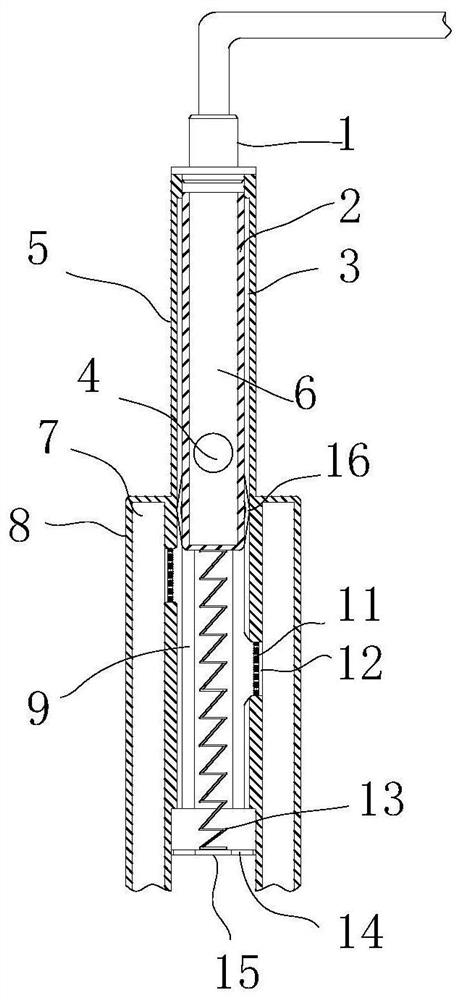

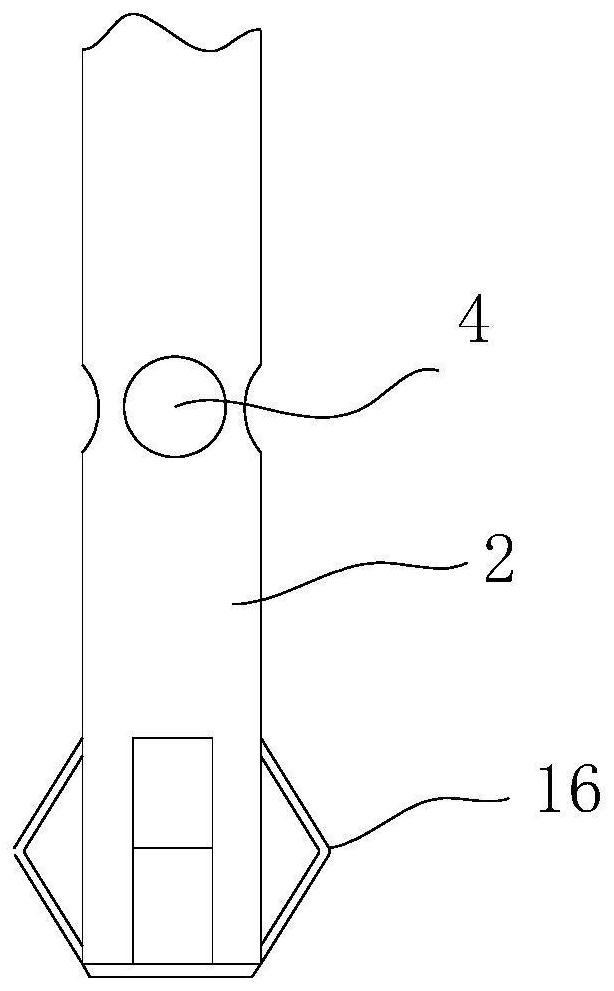

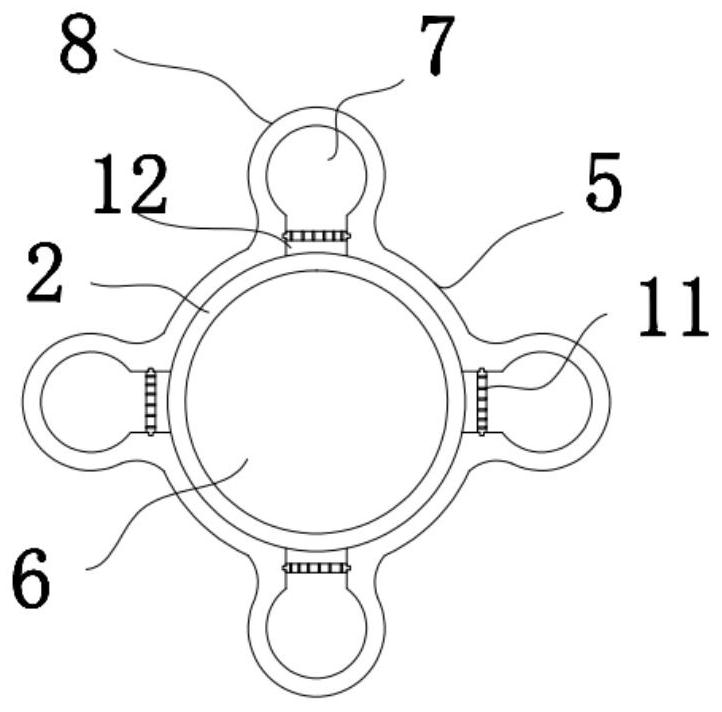

[0016] Such as figure 1 As shown, in this environmental protection composite pipe, a water inlet main pipe 5 is selected, and then a drain pipe 8 is respectively arranged on the four outer surfaces of the water inlet main pipe 5, and the drain pipe 8 and the water inlet main pipe 5 can be integrated. It can also be a bonded split structure, the drain pipe 8 has a drainage channel 7 inside, the water inlet main pipe 5 has a water inlet channel 9, and a movable part 2 is installed in the water inlet channel 9, and the movable part 2 has a top In the open water inlet chamber 6, a first drain hole 12 is arranged between each drain pipe 8 and the water inlet main pipe 5, and the first drain hole 12 connects the drain channel of the corresponding drain pipe with the water inlet channel. The first drain holes 12 between the drain pipe 8 and the water inlet main pipe 5 are not arranged in the same horizontal plane and there is no overlap between the first drain holes 12. Therefore, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com