Strawberry wine and making method thereof

A kind of strawberry wine and strawberry technology, applied in the field of strawberry wine, can solve the problems of unstable taste, insufficient aftertaste, prominent sour taste, etc., and achieve the effect of improving taste and quality, full aftertaste, and strong fruity aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Strawberry wine

[0034] The above-mentioned strawberry wine is prepared from raw materials comprising the following parts by weight:

[0035] 490 parts of strawberries, 50 parts of rock sugar, 10 parts of honey and 350 parts of water.

[0036] 2. Preparation method

[0037] The preparation method of above-mentioned strawberry wine, comprises the steps:

[0038] (a) Crushing strawberries into pulp and putting them into a fermenter, adding potassium metabisulfite and pectinase at 20° C. for 6.5 hours, wherein the mass ratio of potassium metabisulfite to strawberry is 4:100000; The mass ratio of the added amount of pectinase to the strawberry is 3: 100000;

[0039] (b) adding activated yeast to the mixture after enzymolysis, and fermenting at 30° C. for 10 days, wherein the mass ratio of the added amount of activated yeast to strawberry is 8:100000;

[0040] (c) Separating, filtering, clarifying and filtering after the fermentation is finished, to obtain the origin...

Embodiment 2

[0043] 1. Strawberry wine

[0044] The above-mentioned strawberry wine is prepared from raw materials comprising the following parts by weight:

[0045] 510 parts of strawberries, 40 parts of rock sugar, 20 parts of honey and 400 parts of water.

[0046] 2. Preparation method

[0047] The preparation method of above-mentioned strawberry wine, comprises the steps:

[0048] (a) Crushing strawberries into pulp and putting them into a fermenter, adding potassium metabisulfite and pectinase at 25° C. for 5.5 hours, wherein the mass ratio of potassium metabisulfite to strawberries is 6:100000; The mass ratio of the added amount of pectinase to strawberry is 2: 100000;

[0049] (b) adding activated yeast to the mixture after enzymolysis, and fermenting at 25°C for 15 days, wherein the mass ratio of the added amount of activated yeast to strawberry is 12:100000;

[0050] (c) Separating, filtering, clarifying and filtering after the fermentation is finished, to obtain the original ...

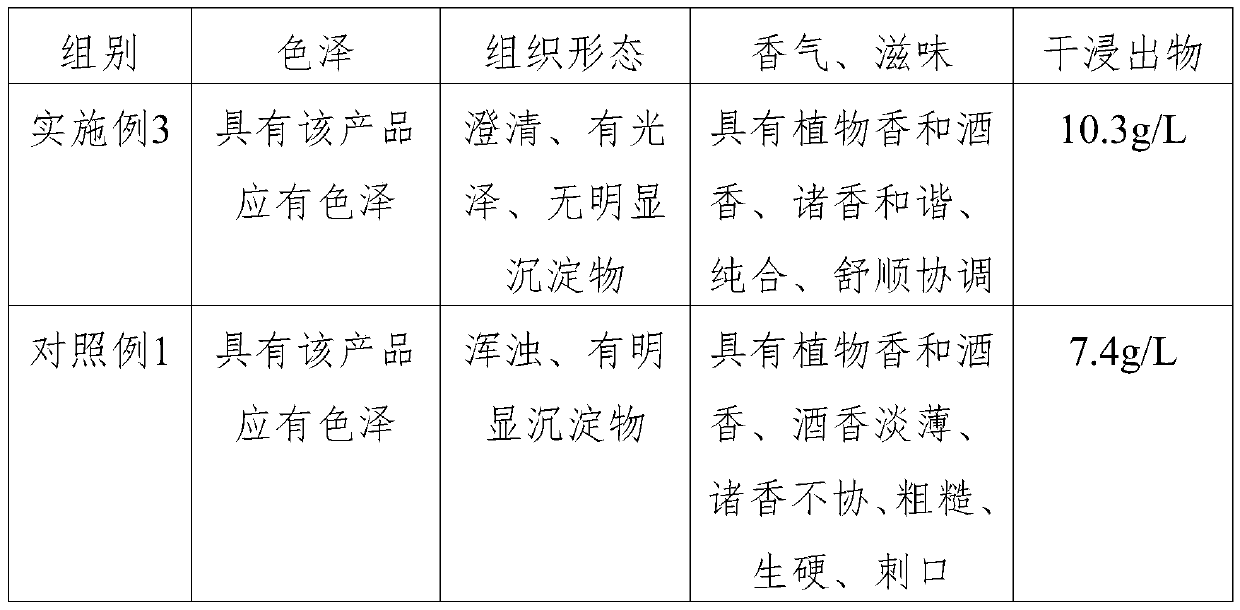

Embodiment 3

[0053] 1. Strawberry wine

[0054] The above-mentioned strawberry wine is prepared from raw materials comprising the following parts by weight:

[0055] 500 parts of strawberries, 45 parts of rock sugar, 15 parts of honey and 380 parts of water.

[0056] 2. Preparation method

[0057] The preparation method of above-mentioned strawberry wine, comprises the steps:

[0058] (a) Crushing strawberries into pulp and putting them into a fermenter, adding potassium metabisulfite and pectinase at 23°C for 6 hours, wherein the mass ratio of potassium metabisulfite to strawberry is 5:100000; The mass ratio of the amount of glue enzyme added to the strawberry is 25: 100000;

[0059] (b) adding activated yeast to the mixture after enzymolysis, and fermenting at 28°C for 12 days, wherein the mass ratio of the added amount of activated yeast to strawberry is 10:100000;

[0060] (c) Separating, filtering, clarifying and filtering after the fermentation is finished, to obtain the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com