Water reducing agent for super slump retaining concrete

A technology of slump-retaining agent and water-reducing agent, which is applied in the field of concrete water-reducing agent, can solve the problems of large-scale bleeding and segregation of concrete, and the setting time is not up to standard, and achieves the effect of solving the problem of bleeding and segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

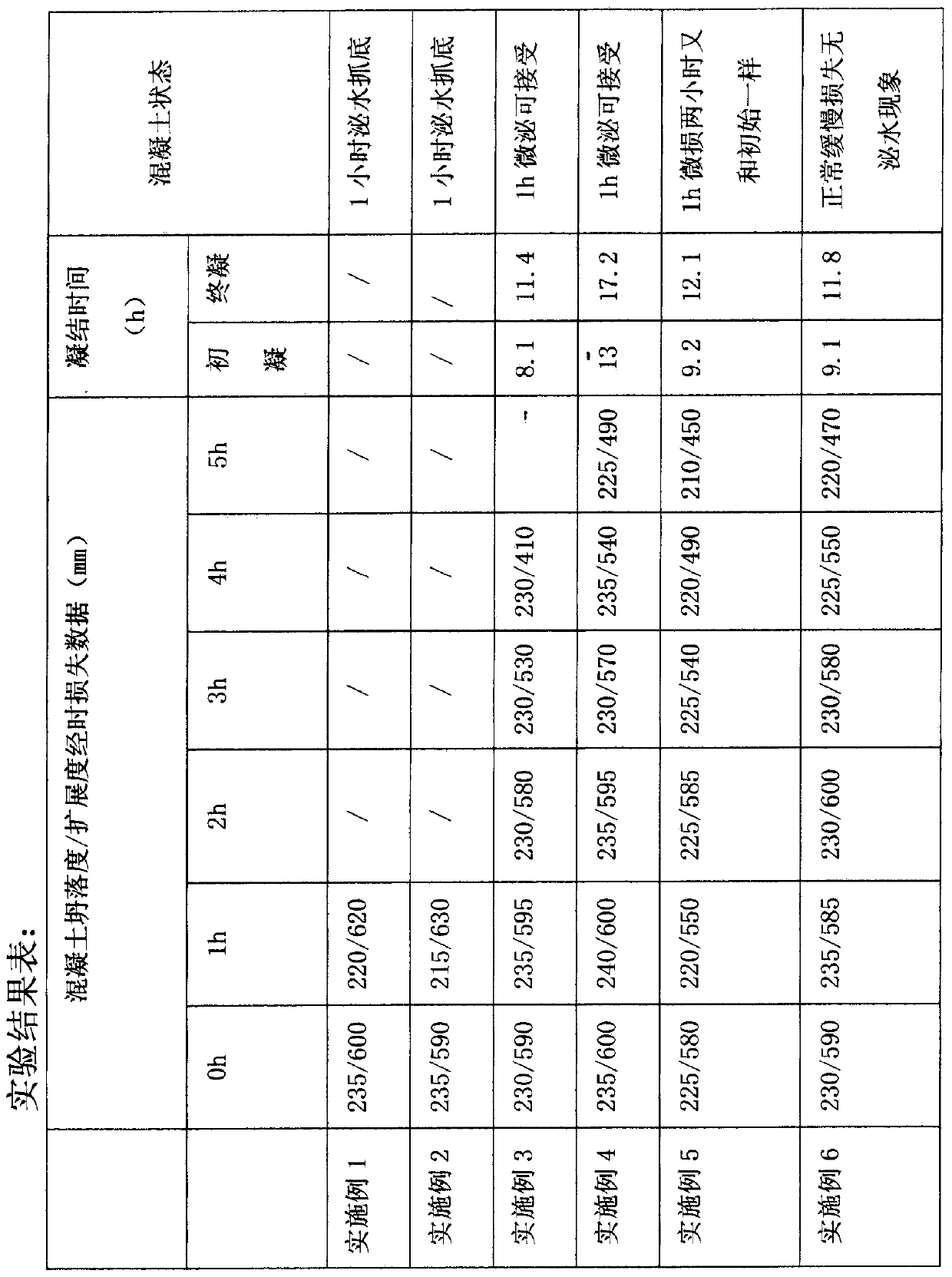

Examples

Embodiment 1

[0017] Example 1: The super-slump-retaining concrete superplasticizer of the present invention is made of the following components and mass percent raw materials: polycarboxylate water-reducer 25%, polycarboxylate slump-retaining agent C series namely Polycarboxylate slump retaining agent C1 8%, retarder namely sodium gluconate 2%, water retaining agent namely acrylic acid 0.1%, air-entraining agent namely sodium lauryl sulfate 0.15%, defoamer namely polydimethylsiloxane Alkanes 0.1%, the remainder is water, and the sum of the mass percentages of each component is 100%. The preparation method of the above-mentioned polycarboxylic acid slump-retaining agent C1 is that the synthetic method is to add 312 parts of polyether macromer isopentenol polyethylene glycol monomethyl ether (2400 molecular weight), 365 parts of deionized water into a 2L three-necked flask , heat and start the agitator to raise the temperature, and at the same time, dissolve 1.6 parts of thioglycolic acid an...

Embodiment 2

[0018]Example 2: The super-slump-retaining concrete superplasticizer of the present invention is made of the following components and mass percent raw materials: polycarboxylate water-reducer 25%, polycarboxylate slump-retaining agent C series 12 %, the retarder is sodium tripolyphosphate 2%, the water retaining agent is the combination of 0.05% hydroxypropyl methylcellulose and 0.5% acrylamide polymer, the air-entraining agent is fatty alcohol polyoxyethylene ether sodium sulfate 0.1 %, the remainder is water, and the sum of the mass percentages of each component is 100%; the above-mentioned polycarboxylate slump retaining agent C series is two raw materials of 6% polycarboxylate slump retaining agent C1 and 6% polycarboxylate slump retaining agent C2 The combination. The preparation method of the above-mentioned polycarboxylic acid slump-retaining agent C1 is that the synthetic method is to add 312 parts of polyether macromer isopentenol polyethylene glycol monomethyl ether ...

Embodiment 3

[0019] Example 3: The super-slump-retaining concrete superplasticizer of the present invention is made of the following components and mass percent raw materials: polycarboxylate water-reducer 25%, polycarboxylate slump-retaining agent C series namely Polycarboxylate slump-retaining agent C2 8%, retarder 2%, the retarder is a combination of white sugar, hydroxyethylidene diphosphonic acid, zinc sulfate, white sugar, hydroxyethylidene diphosphonic acid, zinc sulfate The mass ratio is 1:2:0.5, water retaining agent 0.55% (that is, the combination of 0.05% hydroxypropyl methylcellulose and 0.5% acrylic acid), air-entraining agent is fatty alcohol polyoxyethylene ether sodium sulfate 0.1%, the remaining For water, the sum of the mass percentages of each component is 100%. The preparation method of the above-mentioned polycarboxylic acid slump-retaining agent C2 is that the synthetic method is to add 320 parts of polyether macromonomer isopentenol polyethylene glycol monomethyl eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com