Small-roll cloth rolling machine

A technology of cloth rolling machine and cloth rolling roller, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of high cost, unsightly edges of cloth rolls, and short history of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

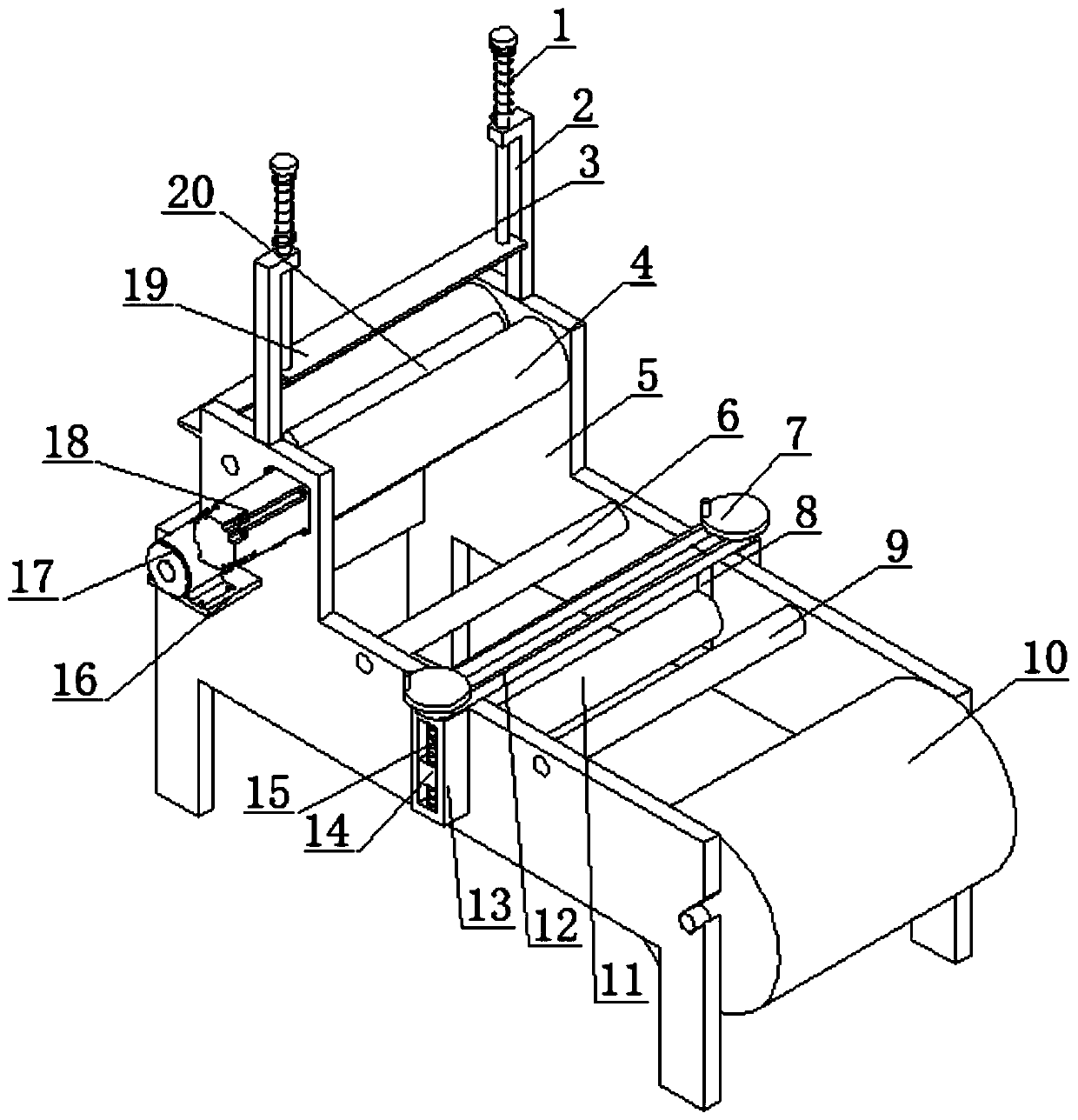

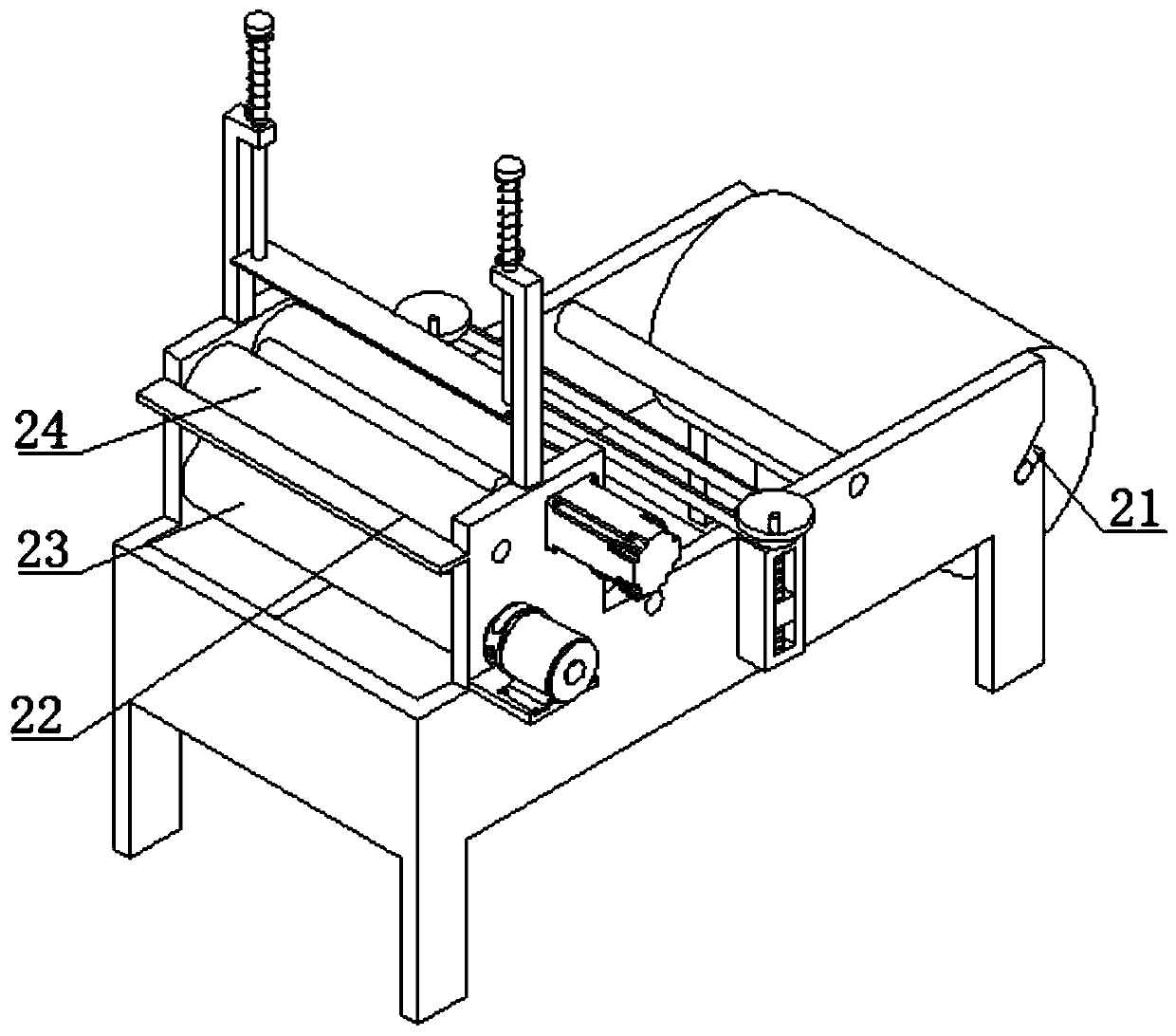

[0021] Such as Figure 1-Figure 7 As shown, the present invention includes a symmetrical L-shaped support plate 5, one end of the horizontal plate of the symmetrical L-shaped support plate 5 is respectively provided with a cloth reel slot 21, and the two ends of the cloth reel of the cloth roll 10 are respectively snapped into the cloth. In the reel slot 21, the horizontal plate of the symmetrical L-shaped support plate 5 is close to one end of the cloth roll 10 and is hinged to the two ends of the cloth guide roller one 9, and the horizontal plate of the symmetrical L-shaped support plate 5 is close to the vertical One end of the plate is hinged to the two ends of the cloth guide roller 2 6, the central axis of the cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com