Sectional material self-bending forming extrusion die

An extrusion die and self-bending technology, applied in the direction of metal extrusion die, etc., can solve problems such as section deformation of profiles, reduce extrusion load, and help extrusion molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

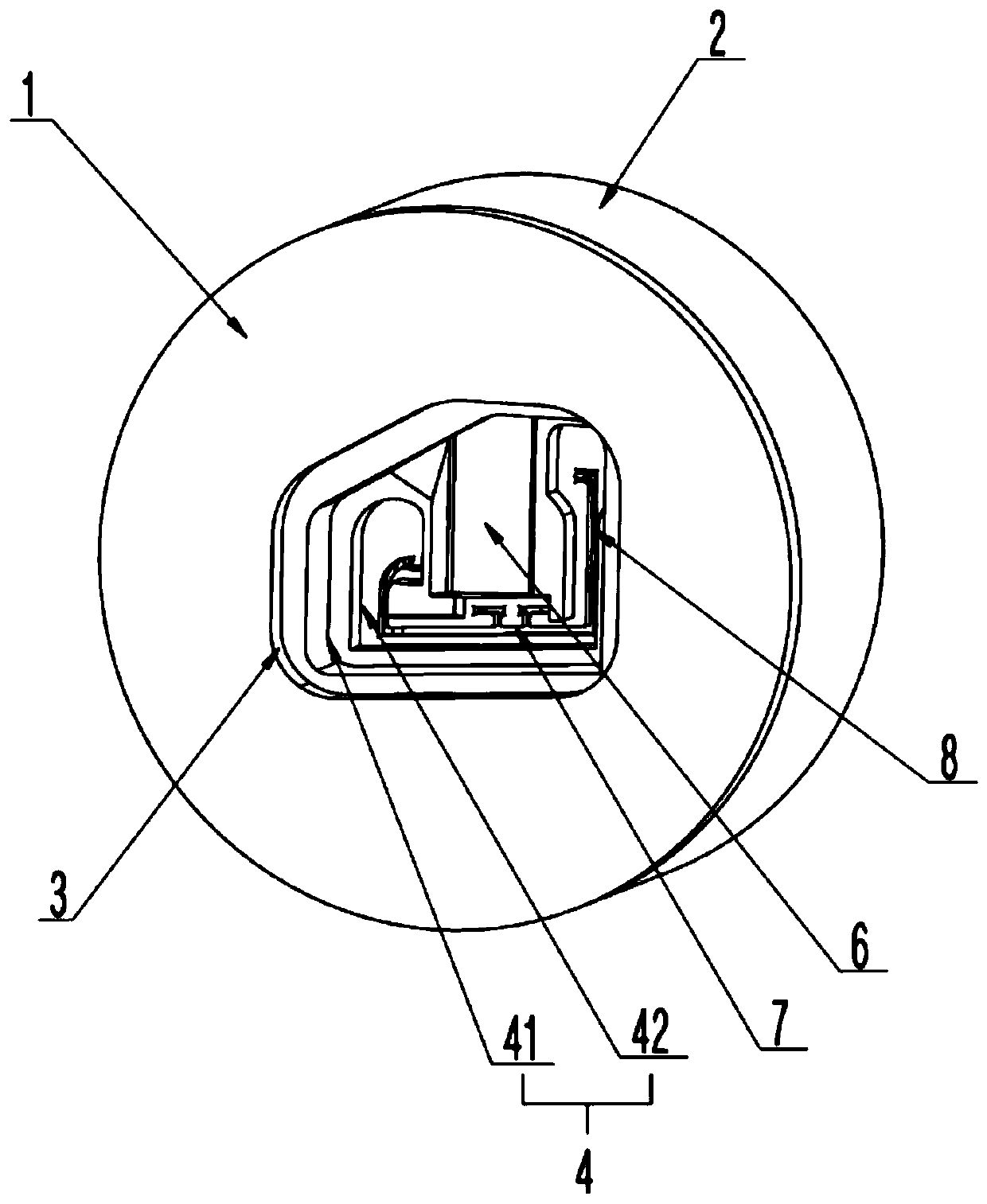

[0030] like figure 1 As shown, the present invention provides a profile self-bending forming extrusion die, comprising a patrix 1 and a lower film 2 connected to the patrix, wherein the patrix 1 and the lower film 2 are interlocked, and the blank (billet) for extrusion ) enters from the upper die 1 and passes through the lower die 2, and is extruded from the lower die 2 by bending.

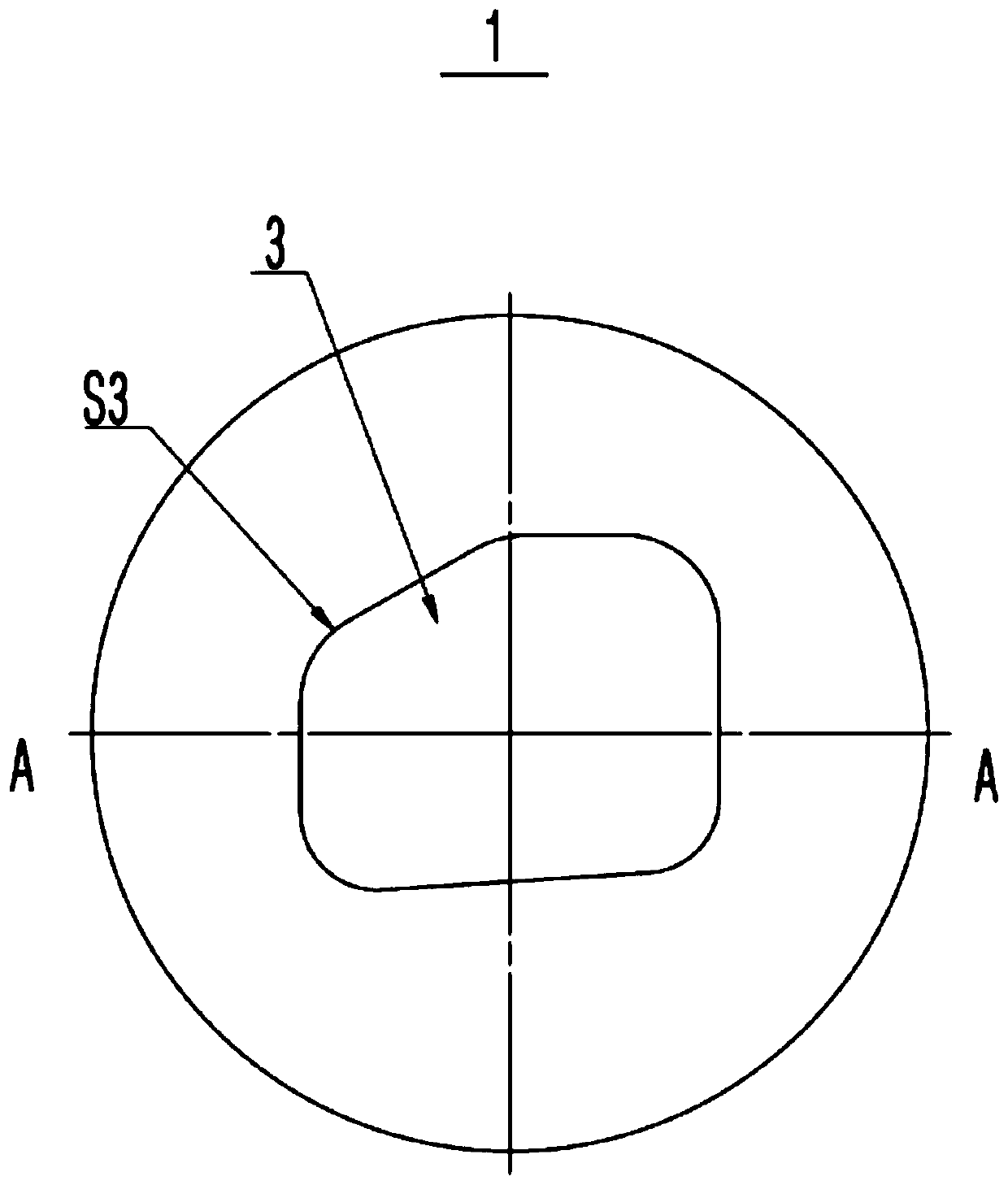

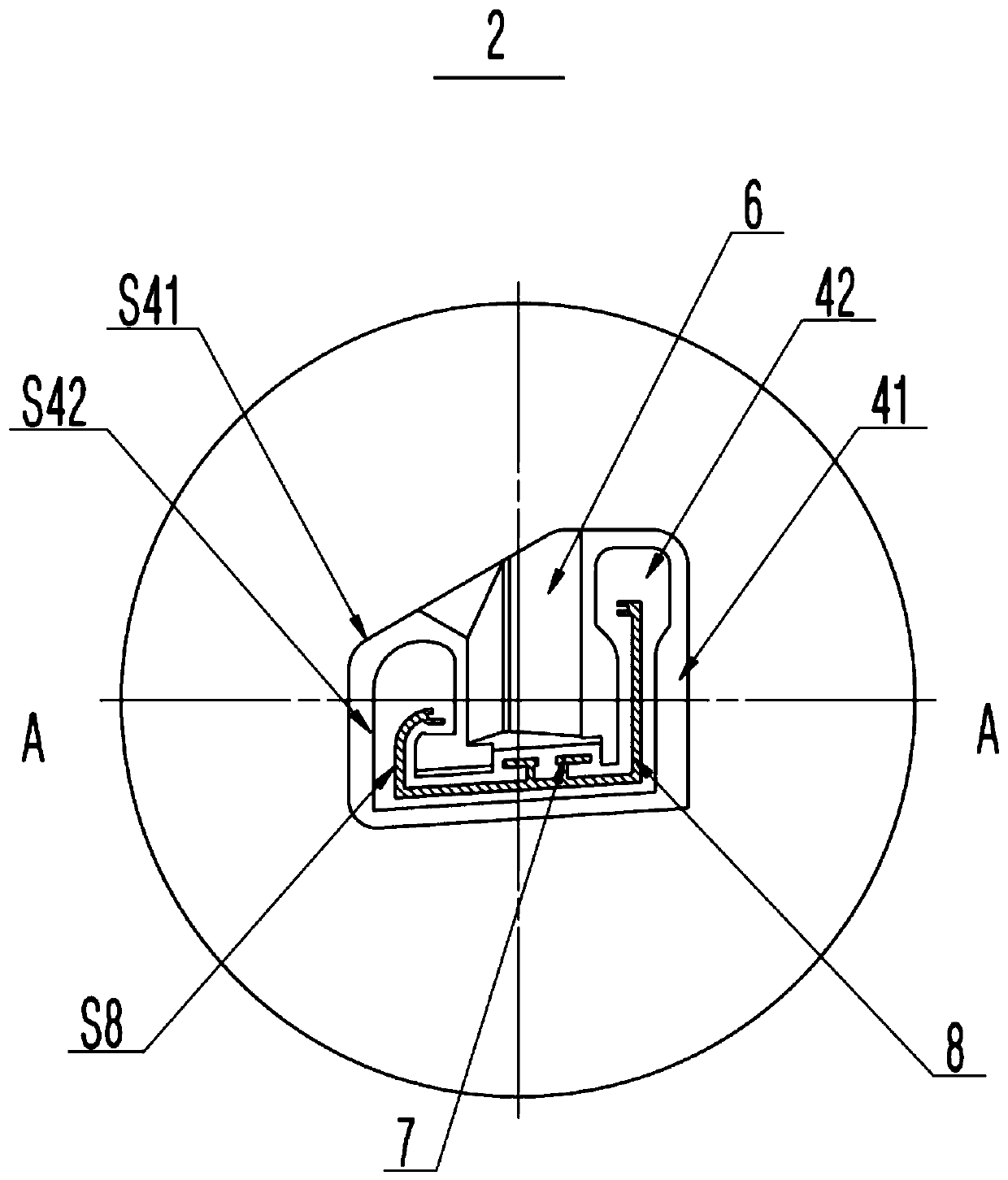

[0031] Specifically, the upper mold 1 is provided with a diversion chamber 3, and the lower film 2 is provided with an extrusion chamber 4 at a position corresponding to the diversion chamber 3, and the billet passes through the diversion chamber 3 and the extrusion chamber 4 in sequence; and The areas covered by the inner contours of the upper half of the diversion chamber 3 and the extrusion chamber 4 are larger than the areas covered by the inner contours of the lower half.

[0032] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com