An Extrusion Die for Small Diameter Thin Wall Deep Blind Hole Parts

A technology of extrusion forming and deep blind holes, which is applied in the field of metal plastic processing, can solve the problems of cumbersome processing procedures, poor quality of finished products, and low yield rate, and achieve the effects of good forming surface quality, reduced stress concentration, and improved mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

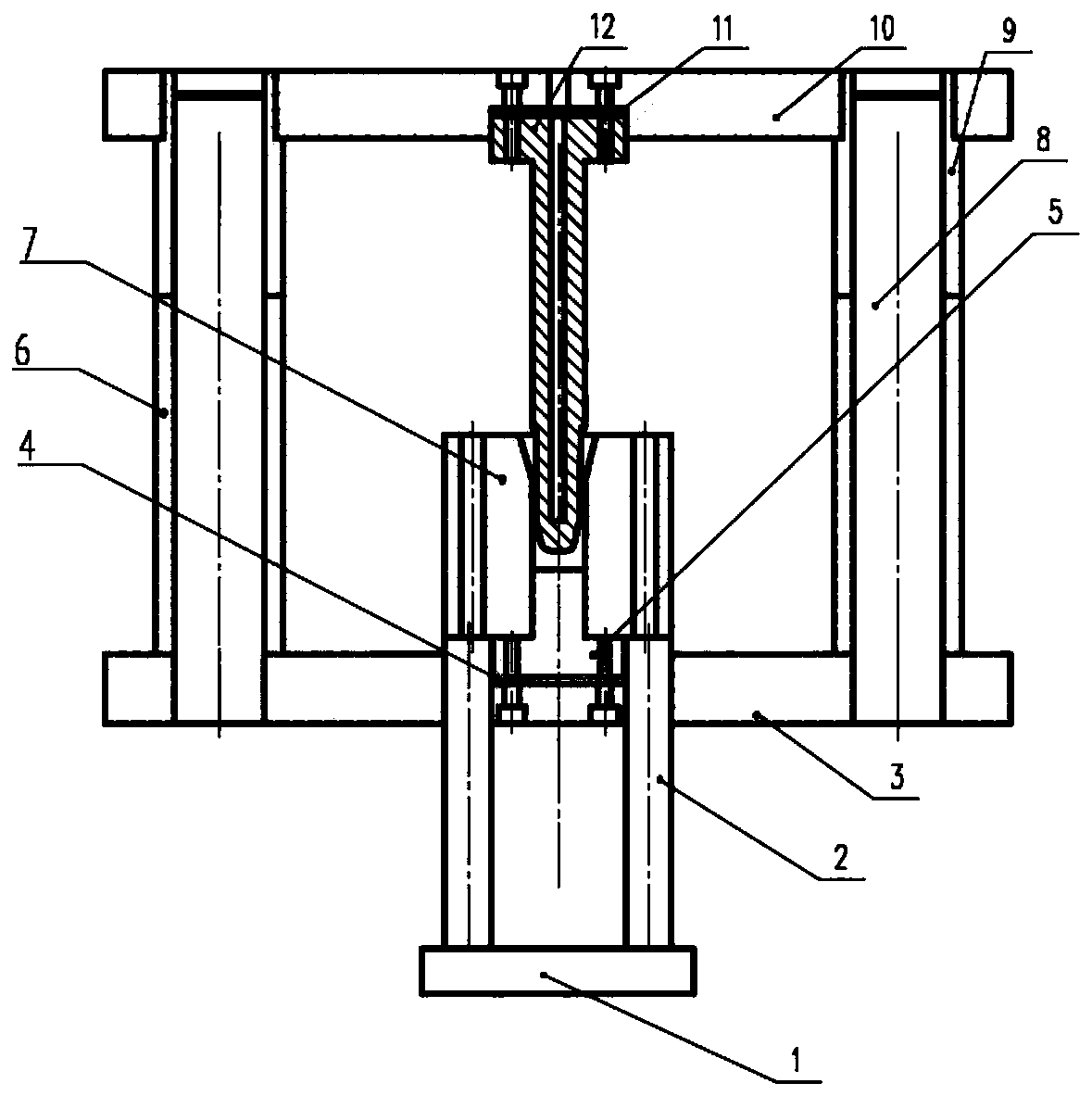

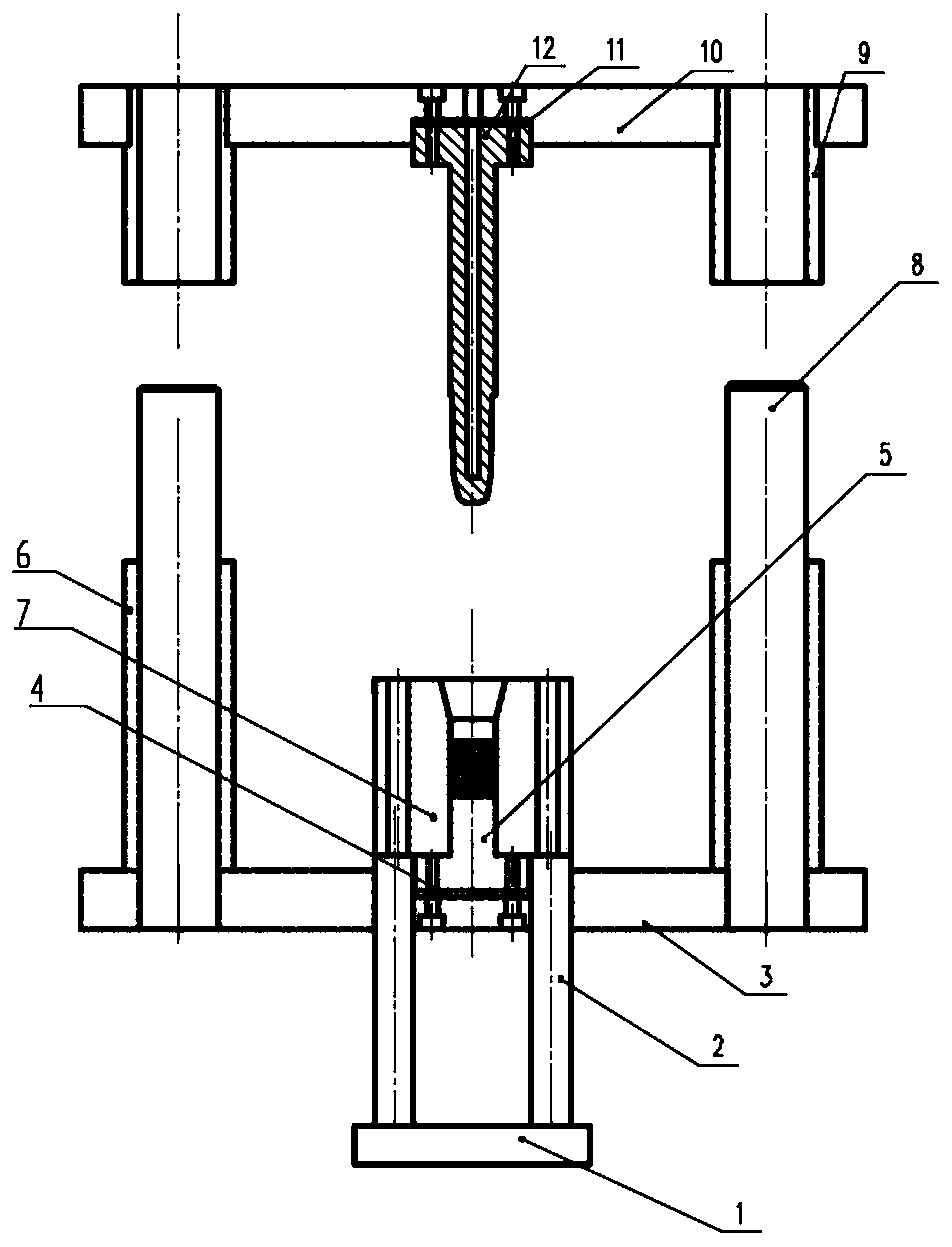

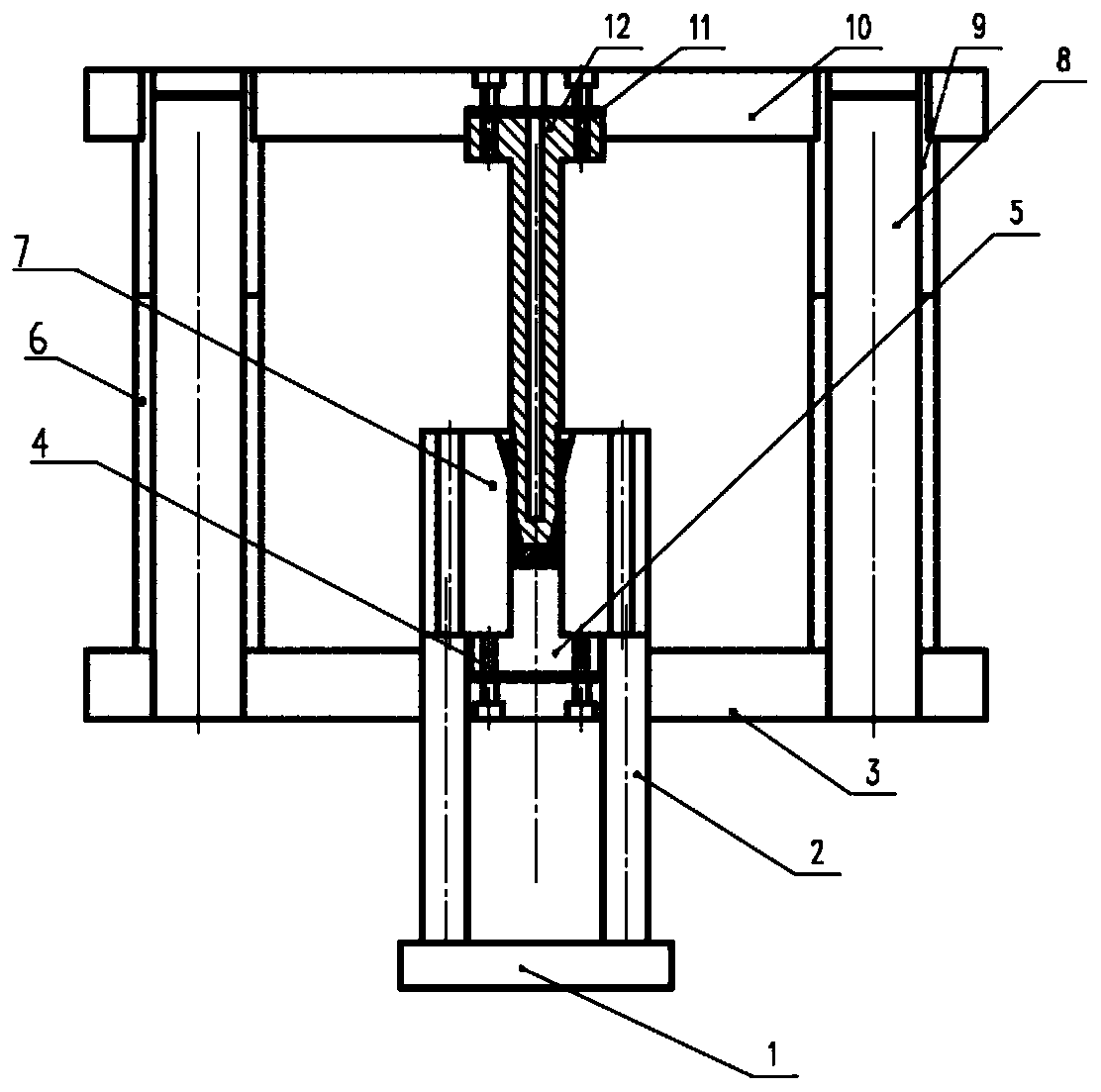

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] The small-diameter thin-walled deep blind hole part in the present invention refers to the inner diameter less than 22mm, the wall thickness less than 2mm, the ratio of the thinnest wall thickness of the blind hole part to the outer diameter is 0.12-0.16, the extrusion ratio is 5-7, hot extrusion Blind hole processing parts with deformation greater than 70%.

[0017] to combine figure 1 , a small-diameter thin-walled deep blind hole extrusion die, including the upper template 10, the lower template 3, the lower mold core 5, connectors, cavity 7, punch 12 and two sets of guide limit components; the upper template 10 Parallelly arranged directly above the lower template 3, the center of the bottom surface of the upper template 10 is provided with a first circular groove, and the center of the bottom of the first circular groove is upwardly opened with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com