Reaction device with uniform heating function for production of organic matter treatment catalyst

A technology of uniform heating and reaction device, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical/physical processes, etc., can solve problems such as poor quality of finished products and achieve good quality of finished products , The design structure is simple and clear, and the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

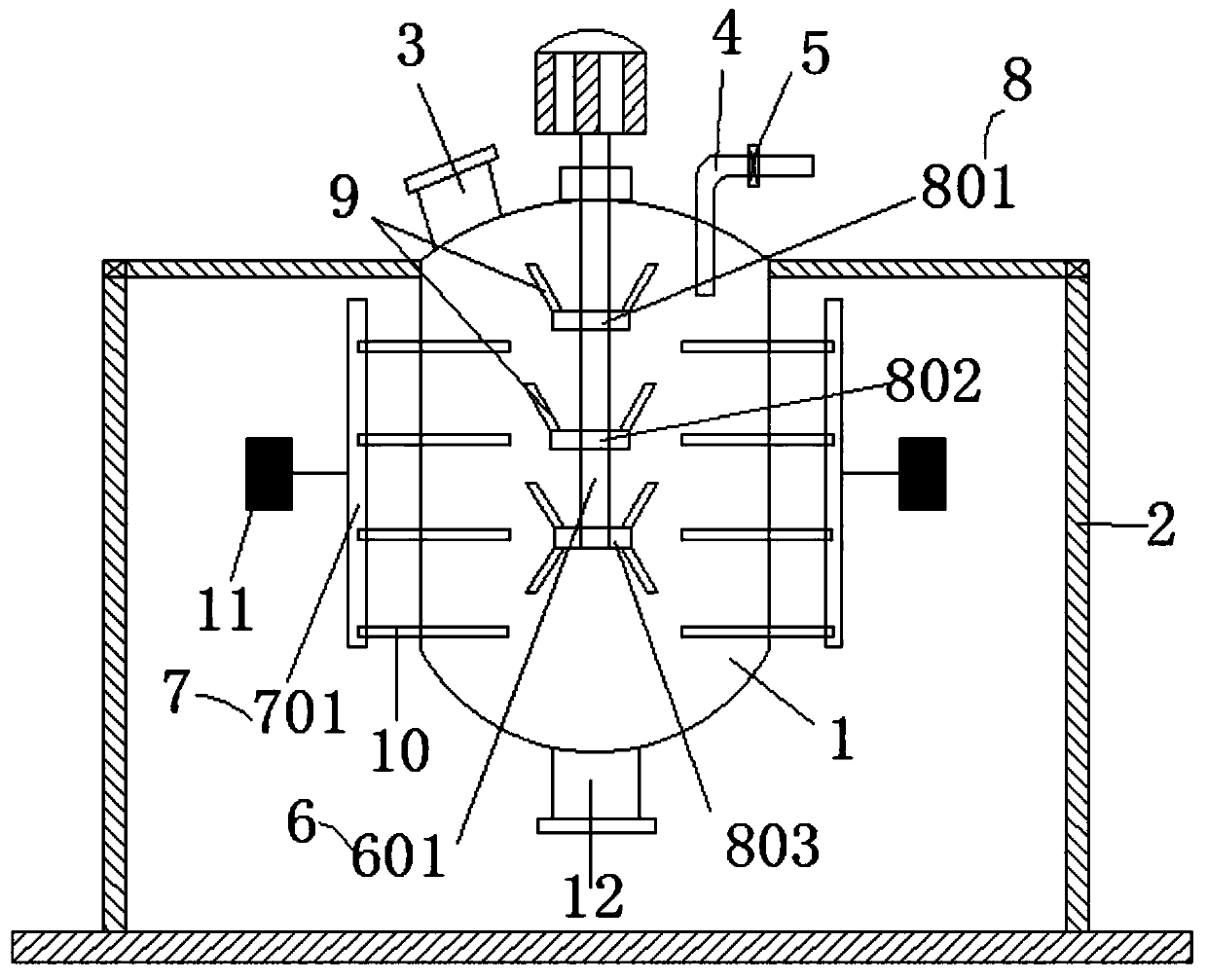

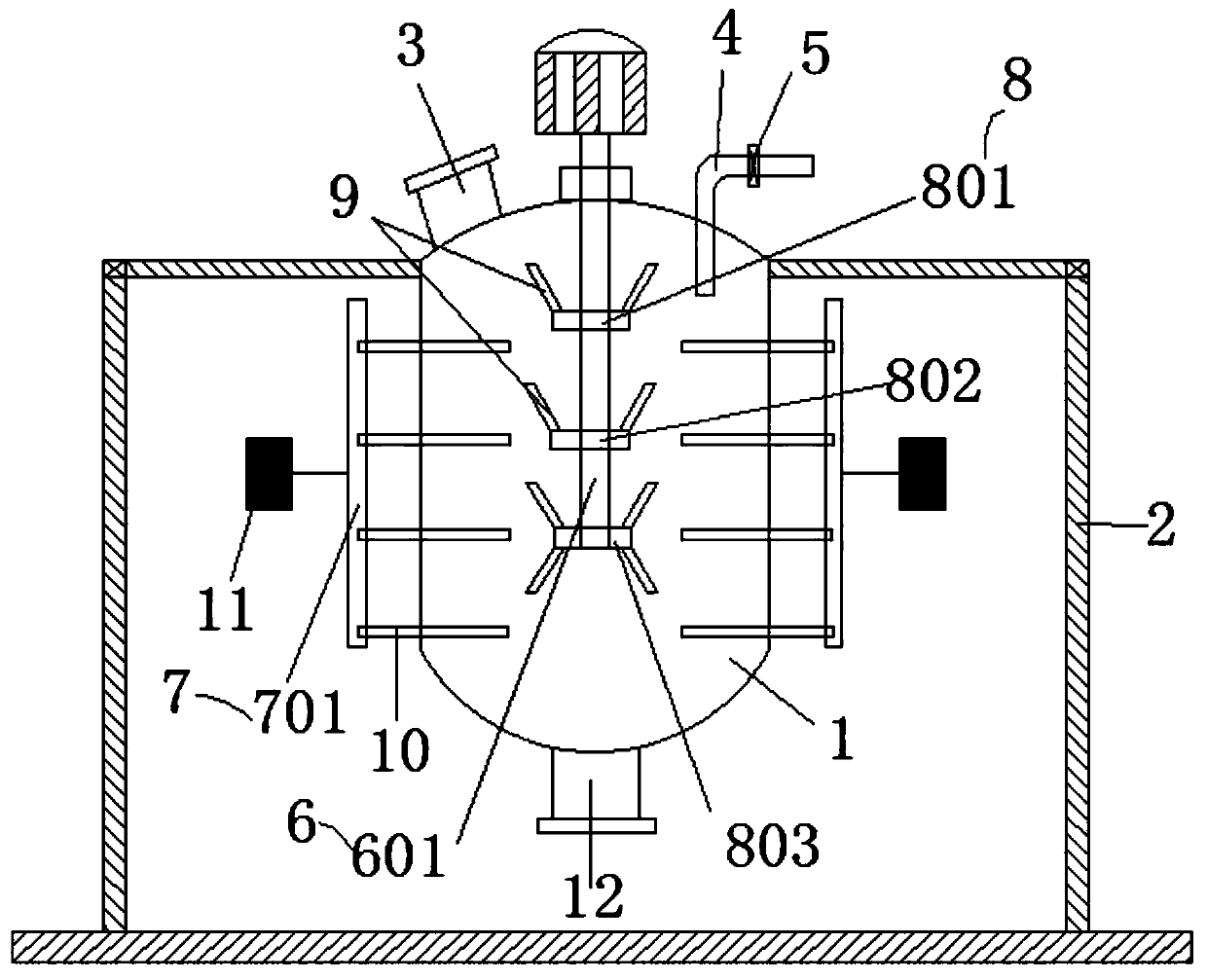

[0017] Embodiment 1: see figure 1 with figure 2 , a uniformly heated reaction device for the production of organic matter treatment catalysts provided by the present invention will now be described, including a reactor body 1, the reactor body 1 is fixed on the frame 2, and the left side of the upper end of the reactor body 1 Feed pipe 3 is set, discharge pipe 12 is arranged at the lower end of described reactor body 1, exhaust pipe 4 is arranged on the right side of the upper end of described reactor body 1, and exhaust valve 5 is set up on the pipeline of described exhaust pipe 4 , the interior of the reactor body 1 is provided with a stirring assembly 6 and a heating assembly 7, the stirring assembly 6 includes a stirring shaft 601, and a cross bar set 8 is installed on the shaft body of the stirring shaft 601, and the cross bar set 8 includes The first crossbar 801, the second crossbar 802 and the third crossbar 803, the upper side of the rod body of the first crossbar 8...

Embodiment 2

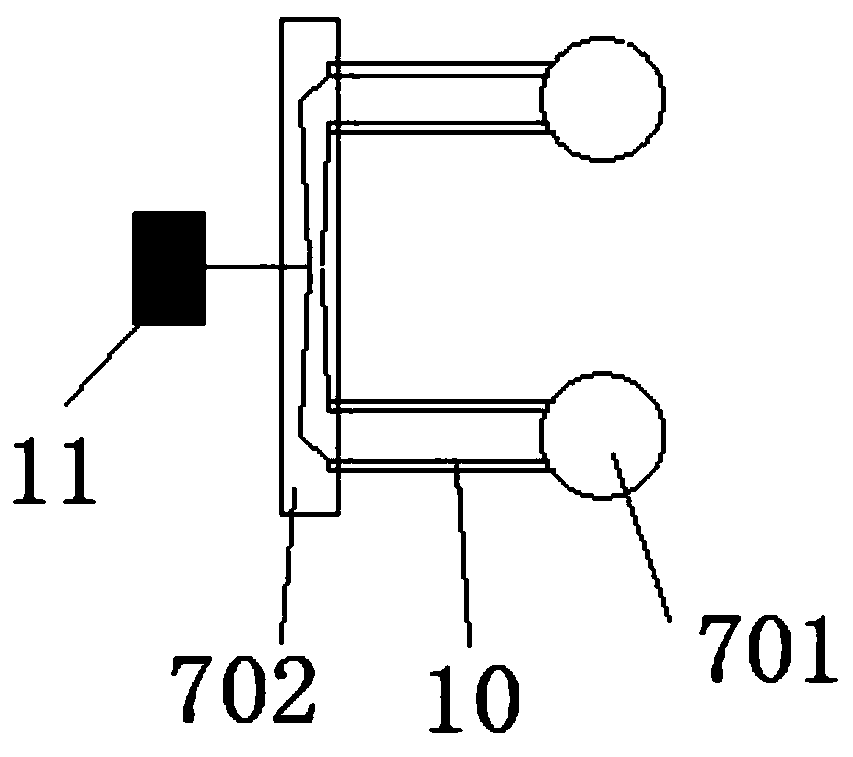

[0018] Example 2: see figure 1 with figure 2 , as an improvement of the present invention, the heating tubes 701 are symmetrically installed on both sides of the bracket 702 .

Embodiment 3

[0019] Embodiment 3: see figure 1 with figure 2 , as an improvement of the present invention, the bracket 702 is installed around the outside of the reactor body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com