A dry powder mixing device

A mixing device and powder technology, applied in mixers, transportation, packaging, dissolution, etc., can solve problems such as troublesome maintenance and replacement, poor continuity, troublesome maintenance, etc., and achieve convenient and labor-saving maintenance, good social significance, and flexible and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

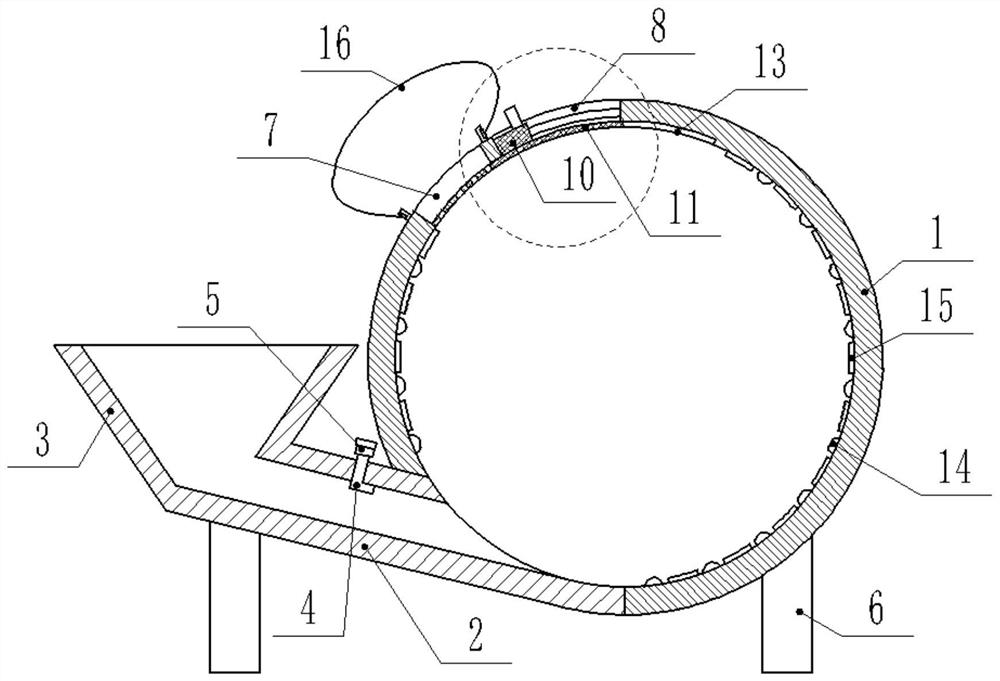

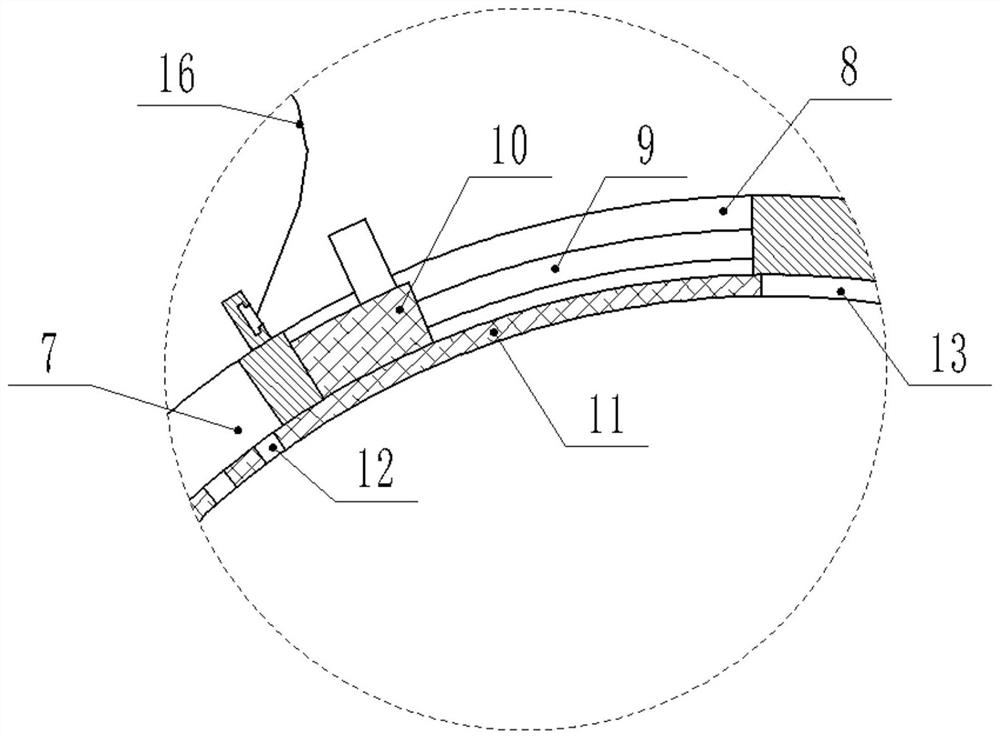

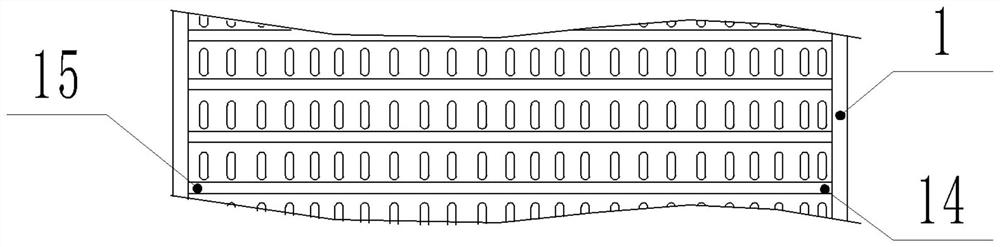

[0014] see Figure 1-3 , a dry powder mixing device, including a mixing cylinder 1 and a feeding tank 2, the feeding tank 2 is arranged obliquely and its lower right end is smoothly connected with the lower left end of the mixing cylinder 1, and the upper left end of the feeding tank 2 is connected with a filler The bucket 3 and the upper end wall of the feed tank 2 are fixedly embedded with a number of nozzles 4, the air outlets 7 of the nozzles 4 are parallel to the feed tank 2 and point to the inside of the mixing cylinder 1, and the air inlets of the nozzles 4 are all led out of the feed tank 2 And it is connected with the Laval nozzle 5, which is connected with the gas storage equipment such as the gas storage tank. 2. The powder falling into the mixing cylinder 1 is tumbled and mixed along its inner wall in the mixing cylinder 1. Using high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com