Proton injection grid VCSEL and preparation method thereof

A proton and grid technology, applied in the field of preparation of proton implanted grid VCSEL, can solve problems such as device reliability degradation, achieve the effects of reducing series resistance, avoiding damage, and stabilizing single transverse mode lasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

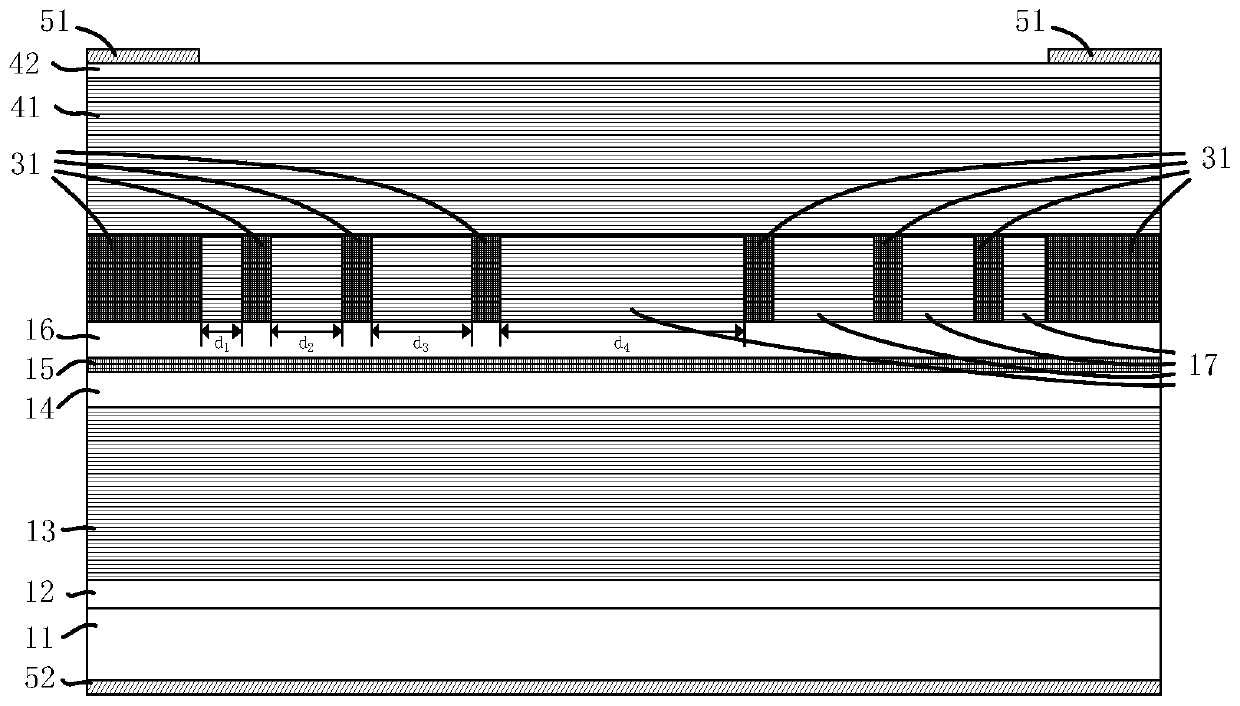

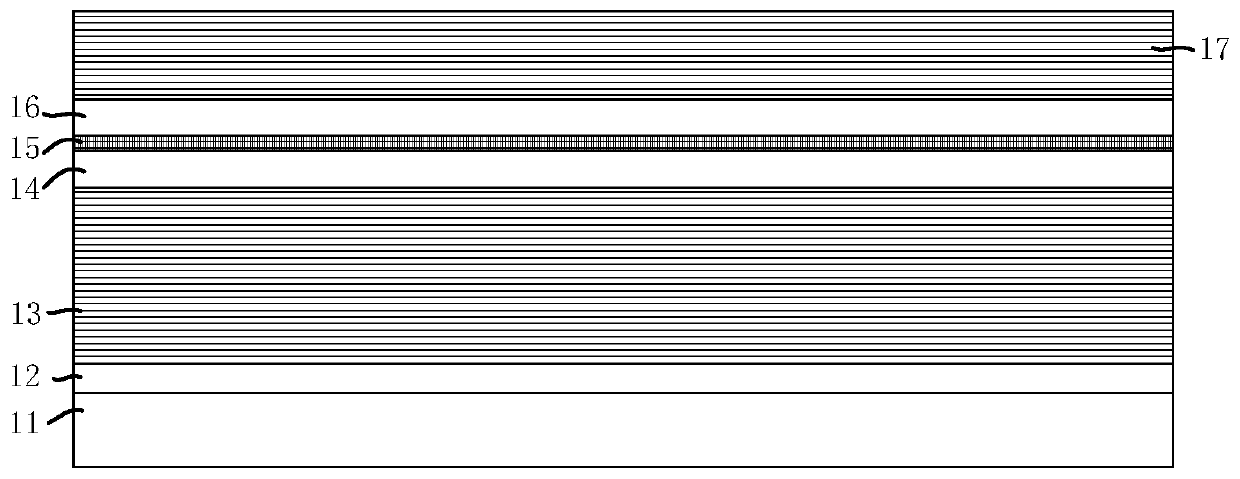

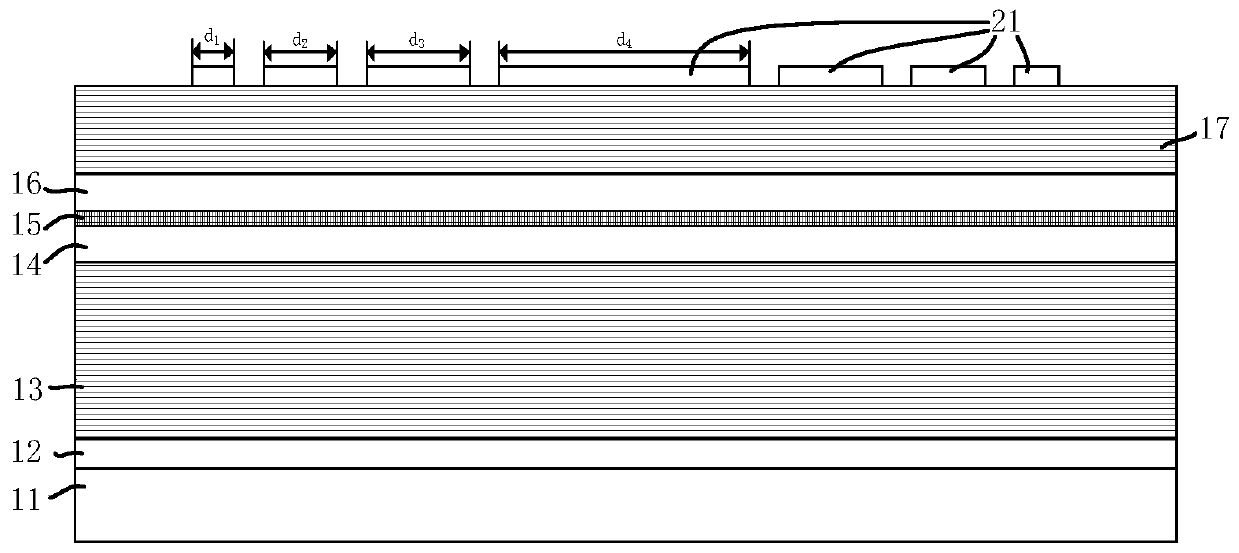

[0026] Refer below figure 1 A proton implanted grid VCSEL structure provided according to an embodiment of the present invention is described. It includes: a conductive GaAs substrate 11, an n-type GaAs buffer layer 12, an n-type AlGaAs / AlAs DBR 13, an AlGaAs lower confinement layer 14, a multi-quantum well light-emitting region 15, an AlGaAs upper confinement layer 16, and an epitaxial p-type AlGaAs / AlAs DBR 17 , proton injection grid structure 31 , secondary epitaxial p-type AlGaAs / AlAs DBR 41 , p-type GaAs ohmic contact layer 42 , n-face electrode 52 and p-face electrode 51 .

[0027] The present invention also provides a preparation method of proton implanted grid VCSEL, comprising the following steps:

[0028] Step 1: Put a conductive GaAs substrate into the MOVCD, raise the temperature in the chamber to 700-750°C, and inject H 2 and AsH 3 , to remove water and oxides from the substrate surface. Lower the temperature to 600-650°C, and pass TMGa, AsH into the chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com