Method for preparing monoolefine-conjugated diene copolymer solution for halogenating

A technology of conjugated diolefins and monoolefins, which is applied in the field of preparation of halogenated monoolefin-conjugated diene copolymer solutions for halogenation, can solve the problems of high content and poor product quality, reduce production costs, improve quality, The effect of simplifying the preparation and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

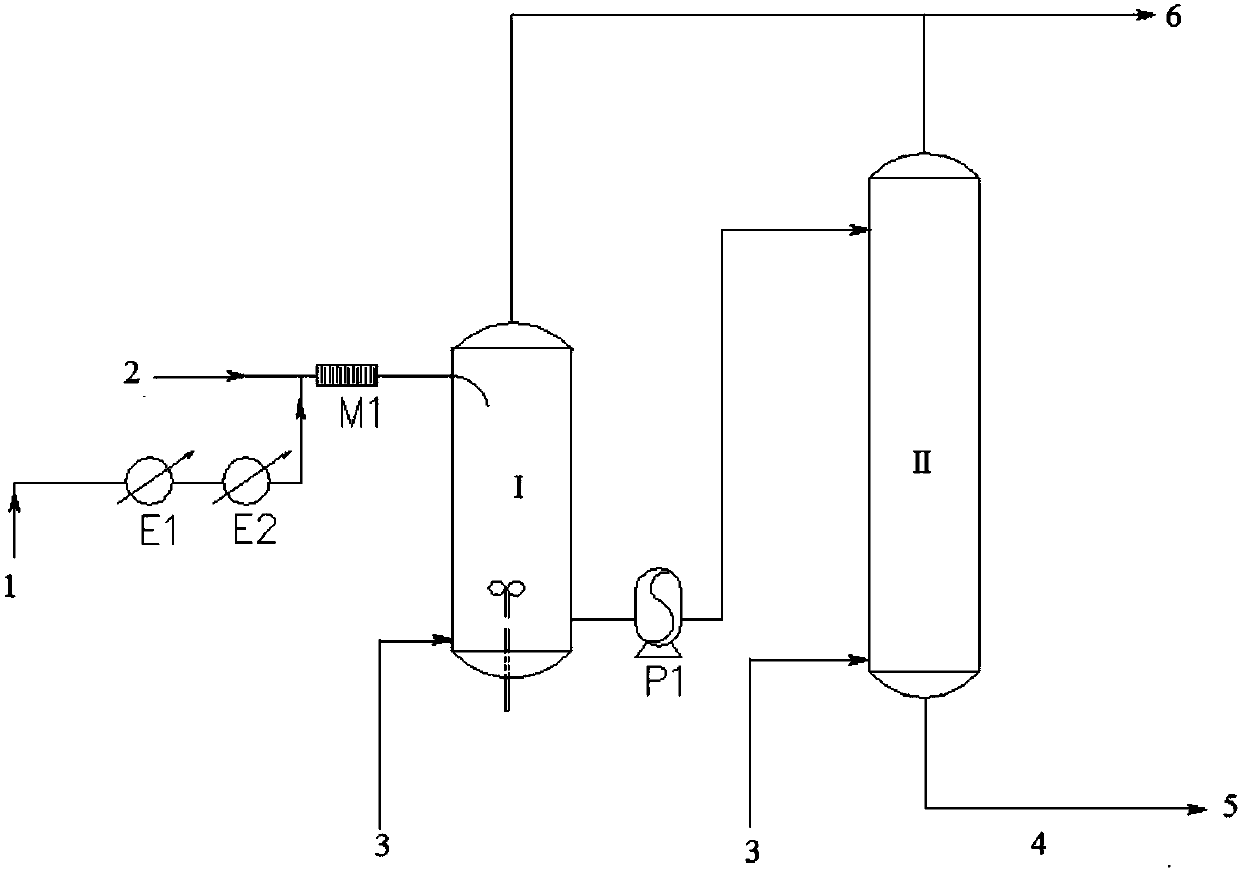

[0026] The invention provides a method for preparing a monoolefin-conjugated diene copolymer solution for halogenation, the method comprising:

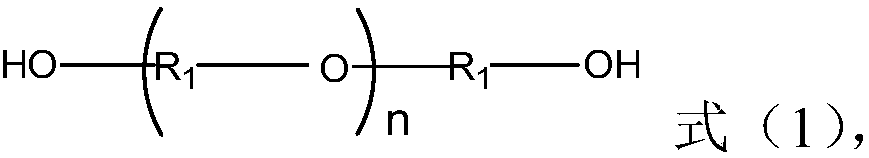

[0027] (1) Mix the terminator solution cooled below -35°C with the monoolefin-conjugated diene copolymer slurry to obtain a monoolefin-conjugated diene copolymer slurry that has lost catalytic activity, wherein the terminator The agent solution contains C 1 -C 2 Halogenated alkanes and saturated fatty alcohols A and optionally C 5 -C 8 The aliphatic alkanes, the saturated fatty alcohol A is C 1 -C 5 Saturated monohydric fatty alcohol, C 2 -C 4 One or more of saturated dibasic fatty alcohols and saturated fatty alcohols shown in formula (1),

[0028]

[0029] Formula (1), R 1 for C 2 -C 3 straight-chain or branched-chain alkyl,

[0030] (2) Use at least one replacement solvent to replace the haloalkane in the monoolefin-conjugated diene copolymer slurry that has lost catalytic activity and remove unreacted monomers to obt...

preparation example 1

[0105] A low-pressure liquid ethylene at -115°C is introduced into the internal cooling pipe of the polymerization reactor, and methylene chloride, isobutene and isoprene are mixed in a certain proportion to form a mixed monomer solution, wherein the moles of isobutene and isoprene The ratio is 45:1, the total monomer concentration is 35wt%, and the mixed monomer solution is gradually cooled to -98°C through propylene and ethylene respectively. The catalyst solution formed by mixing the catalysts ethylaluminum dichloride and methylene chloride in a certain proportion is also gradually cooled to -95°C through propylene and ethylene respectively, and the catalyst concentration is 0.25wt%. The cooled monomer solution and catalyst solution are respectively sent to the polymerization reactor under flow control, and contact in the polymerization reactor to carry out cationic polymerization reaction. The polymerization heat is removed by -115°C low-pressure liquid ethylene, and the po...

preparation example 2

[0108] A low-pressure liquid ethylene at -115°C is introduced into the internal cooling pipe of the polymerization reactor, and methylene chloride, isobutene and isoprene are mixed in a certain proportion to form a mixed monomer solution, wherein the moles of isobutene and isoprene The ratio is 99:1, the total monomer concentration is 40wt%, and the mixed monomer solution is gradually cooled to -98°C through propylene and ethylene respectively. The catalysts, ethylaluminum dichloride and methylene chloride, are mixed in a certain proportion and gradually cooled to -95° C. through propylene and ethylene respectively, wherein the concentration of the catalyst is 0.25 wt%. The cooled monomer solution and catalyst solution are respectively sent to the polymerization reactor under flow control, and contact in the polymerization reactor to carry out cationic polymerization reaction. The polymerization heat is removed by -115°C low-pressure liquid ethylene, and the polymerization temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com