Intelligent automatic window frame production line of robot

A robot and production line technology, applied in the field of robot intelligent automatic window frame production line, can solve the problems of accumulation of debris in window frame chamfering equipment, affecting the production accuracy and quality of window frame, etc., and achieve the effect of ensuring normal operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

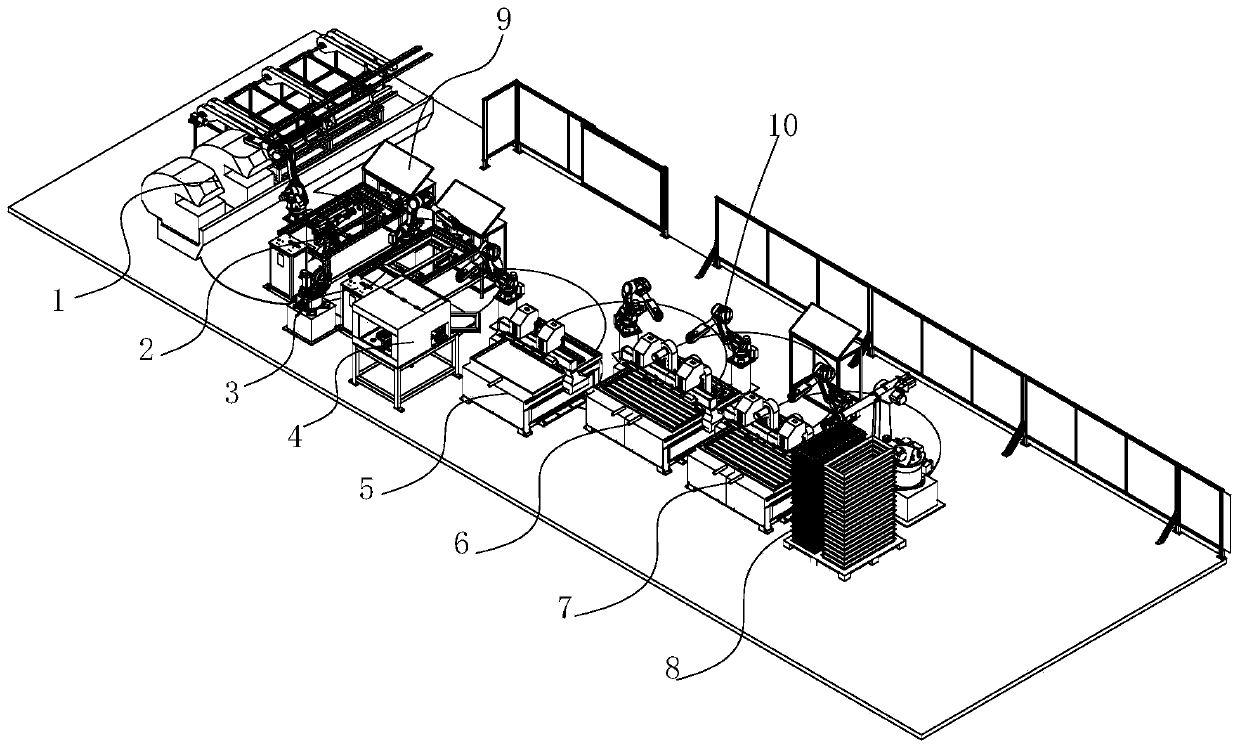

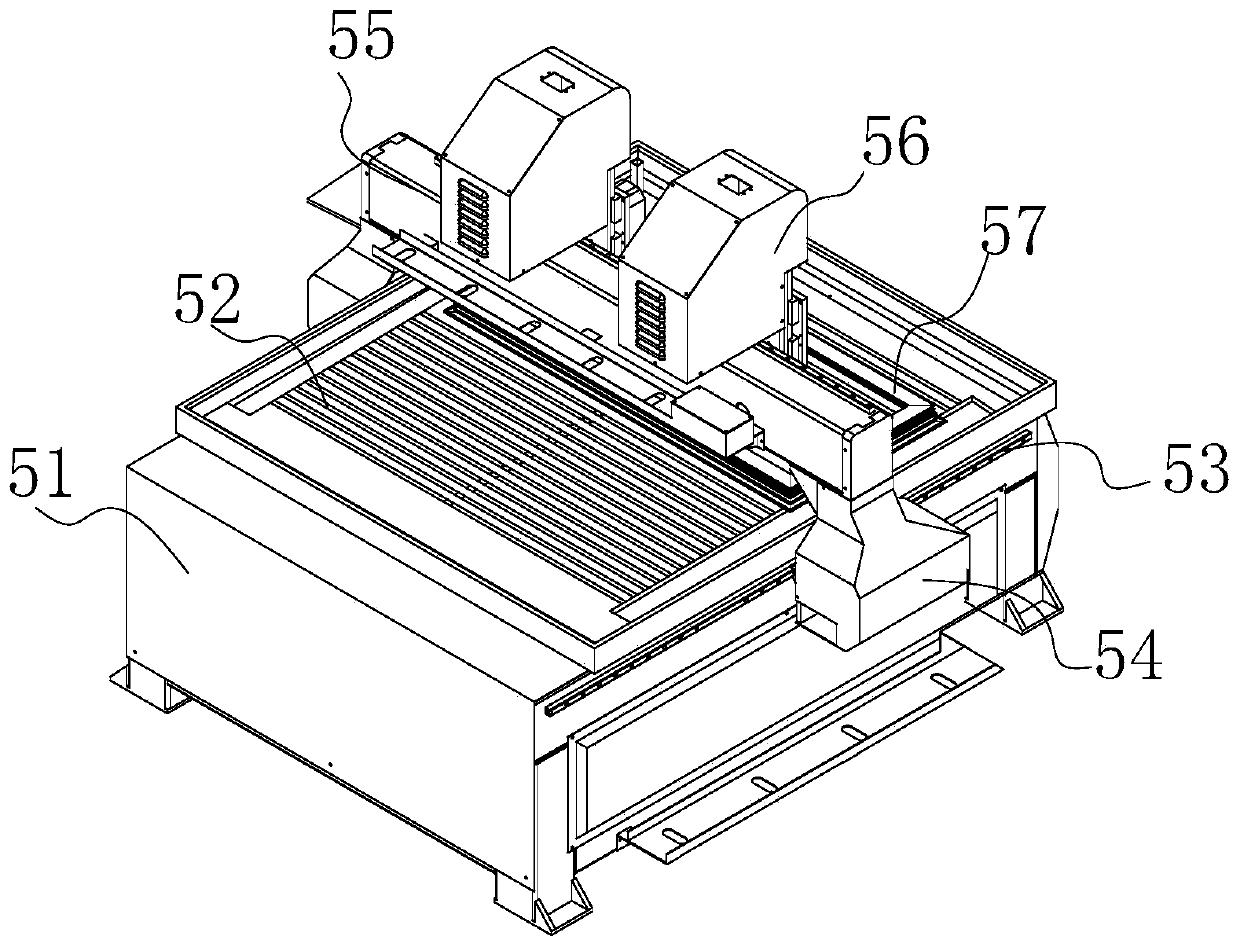

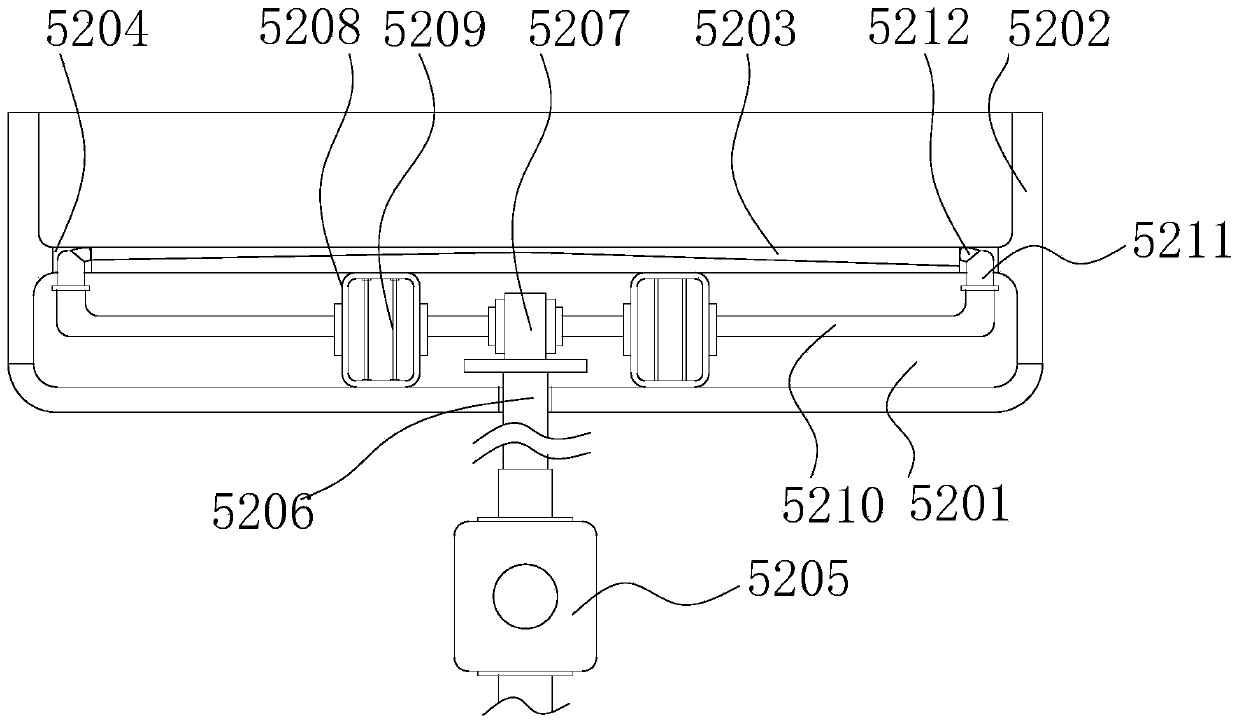

[0021] Such as Figure 1-4 As shown, the present invention provides a technical solution: a robot intelligentized automatic window frame production line, including sawing machine equipment 1, a first welding bed 2 is installed on the right side of the sawing machine equipment 1, and a first welding bed 2 is installed on the right side of the first welding bed 2 The second welding bed 3, the milling machine 4 is installed on the right side of the second welding bed 3, the rounding machine tool 5 is installed on the right side of the milling machine 4, and the first rough grinding machine is installed on the right side of the rounding machine tool 5 6. A second rough grinder 7 is installed on the right side of the first rough grinder 6, and a stacking seat 8 is installed on the right side of the second rough grinder window 7. The first welding bed 2, the second welding bed 3 and the first rough grinder The rear side of 6 is fixedly equipped with transfer table 9, saw machine equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com