Disc brake for a utility vehicle, and brake pad set

A technology of disc brakes and brake linings, applied in the direction of brake types, axial brakes, brake components, etc., can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

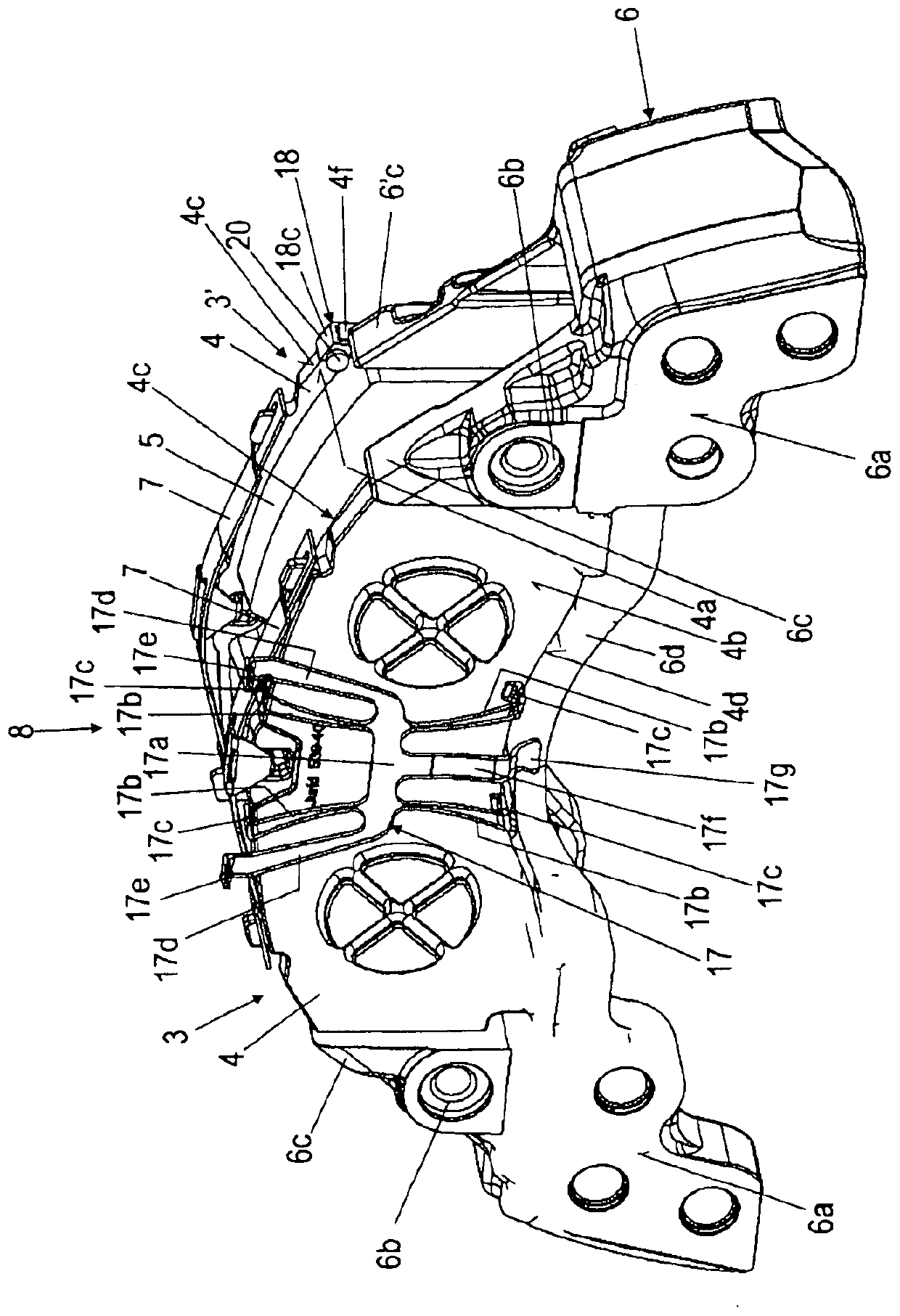

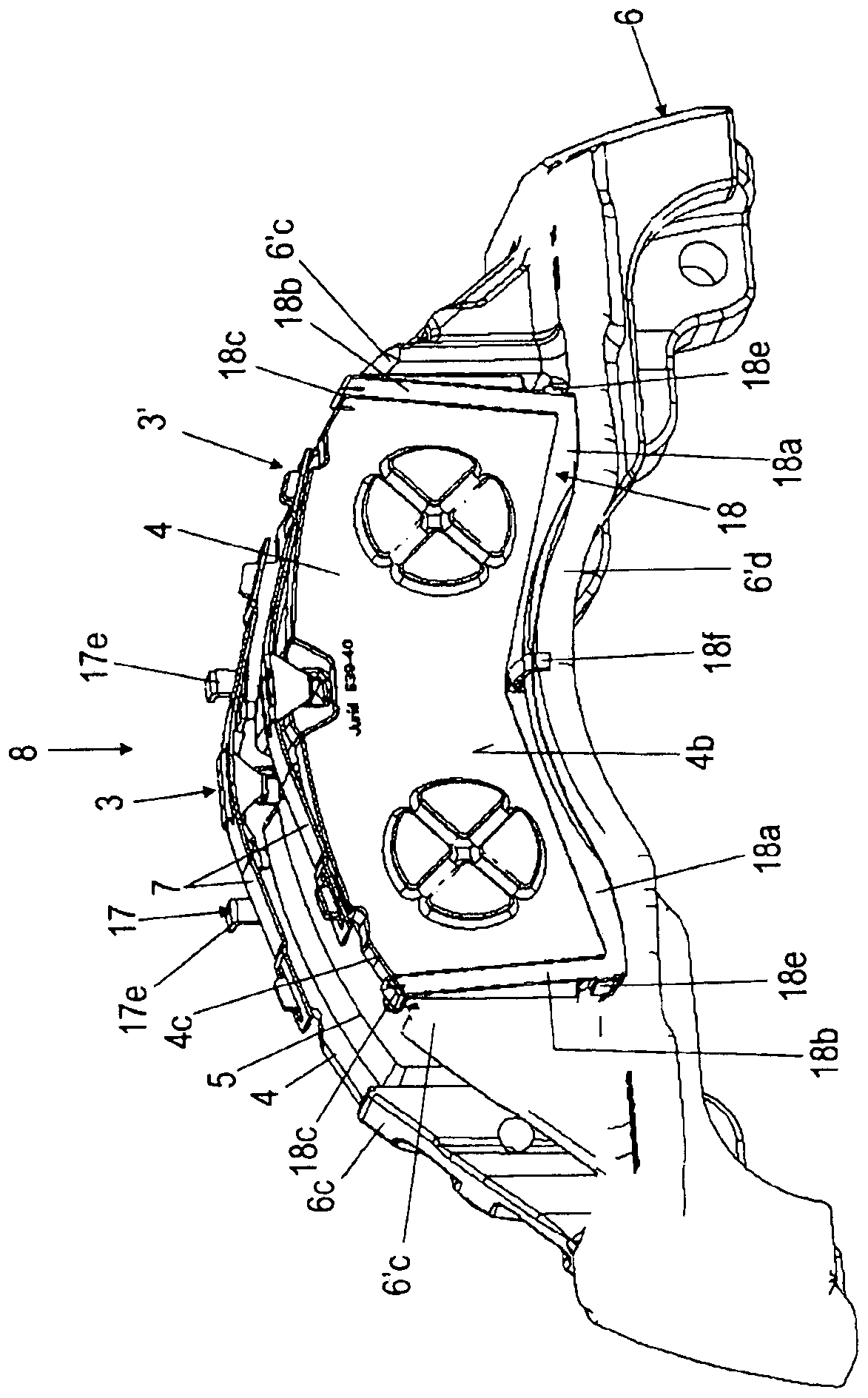

[0096] The terms "upper", "lower", "left", "right" relate to the corresponding arrangement in the figures.

[0097] The “upper side” and the “lower side” of the brake lining 3 , 3 ′ or of the lining support plate 4 always refer to the installation situation of the respective brake lining 3 , 3 ′. In this case, the lower side of the respective brake lining 3 , 3 ′ is closer in the radial direction to the brake disk axis of rotation 2 a of the brake disk 2 than the upper side of the brake lining 3 , 3 ′.

[0098] The term “transverse axis” of the brake lining 3 , 3 ′ refers to an imaginary axis which, in the installed state of the brake lining 3 , 3 ′, extends radially to the axis of rotation 2 a of the brake disk. The “longitudinal axis” of the brake linings 3 , 3 ′ thus extends perpendicularly to said transverse axis and tangentially to the brake disc 2 .

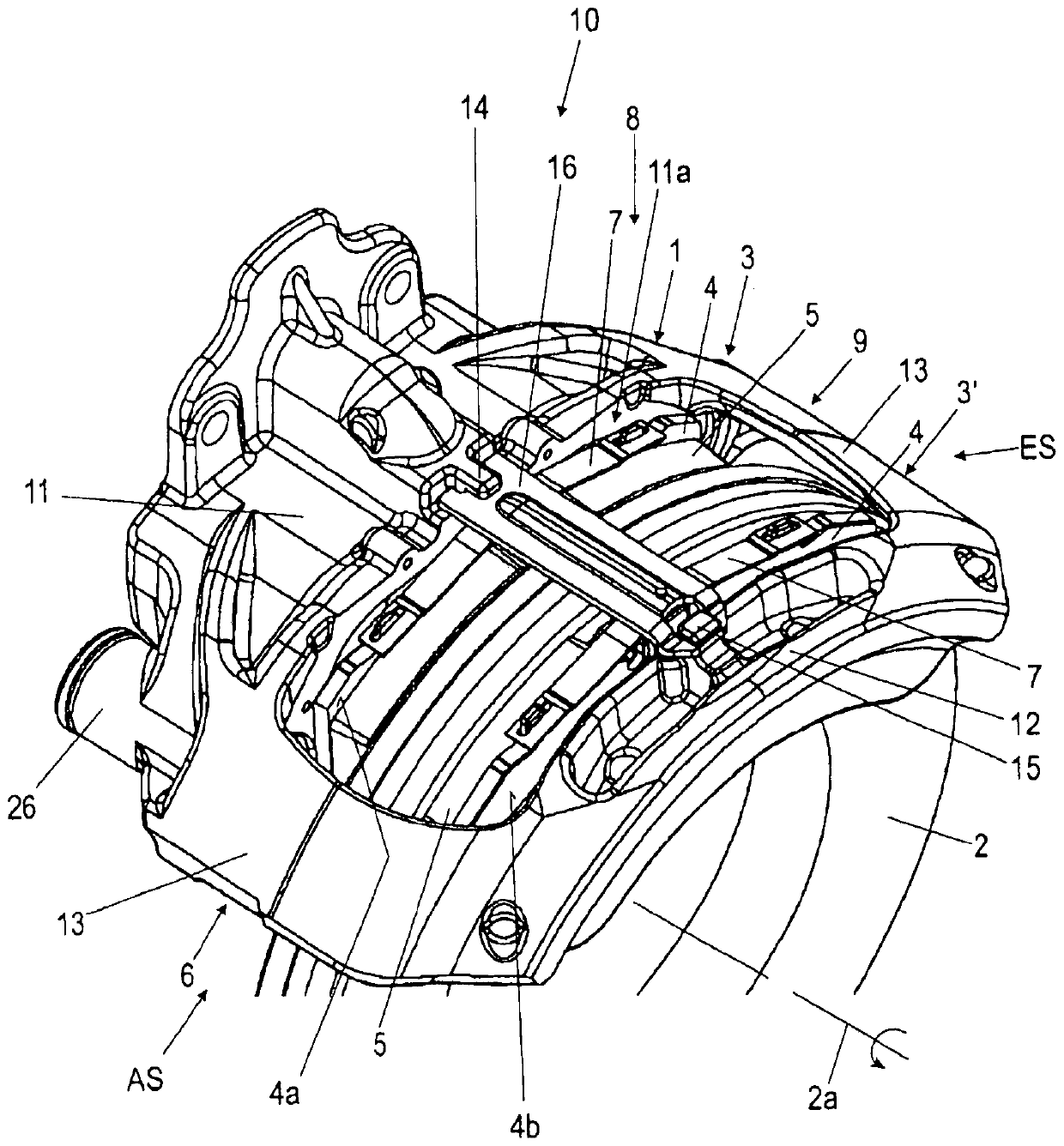

[0099] figure 1 A schematic perspective view of an exemplary embodiment of a disk brake 10 according to the invention w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com