Integrated circuit chip photoresist removing device and process

A photoresist removal and integrated circuit technology, applied in the processing of photosensitive materials, etc., can solve the problems of consumption, excessive degumming cost, turbulent flow, etc., to improve the removal efficiency and reduce the residual defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

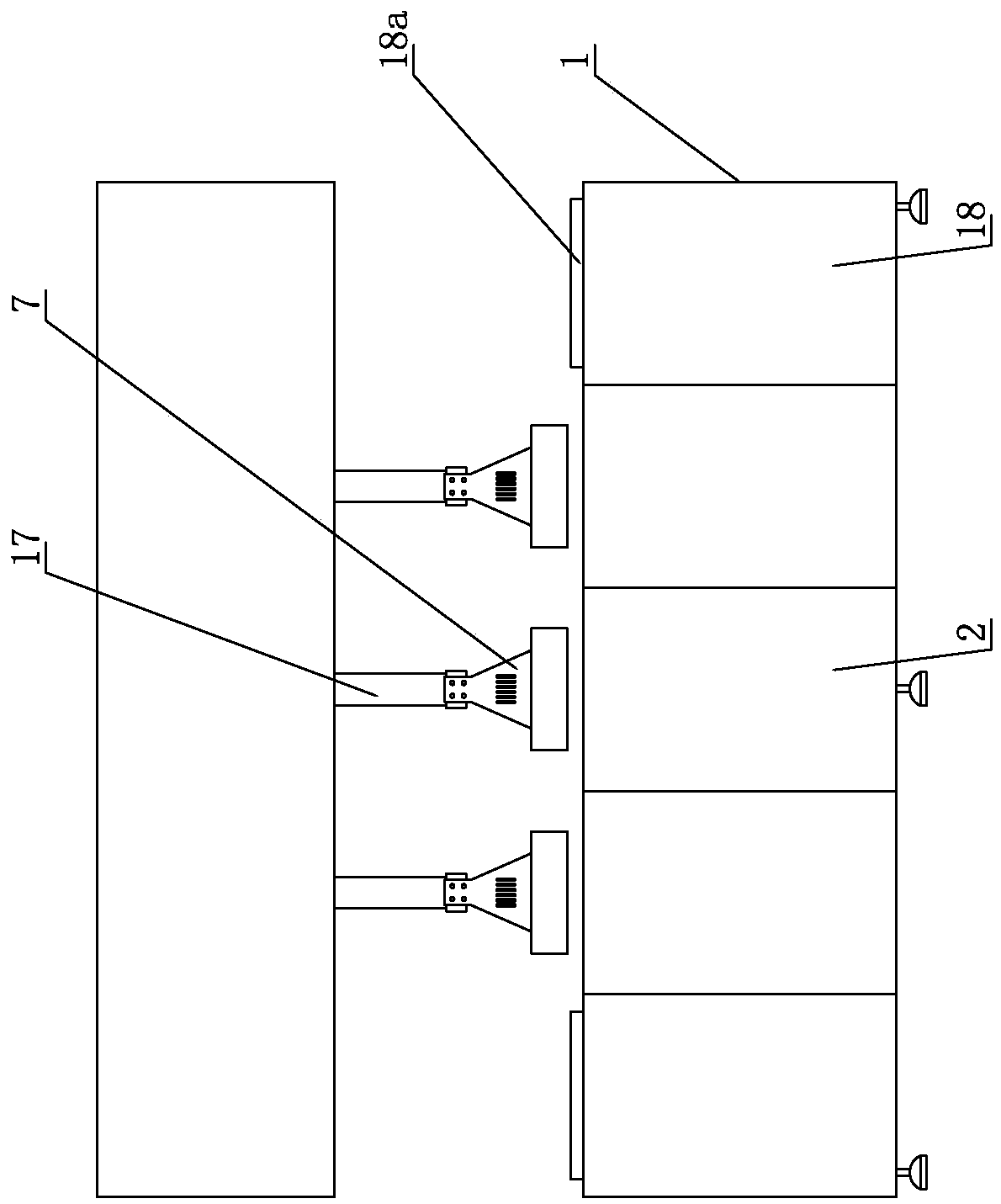

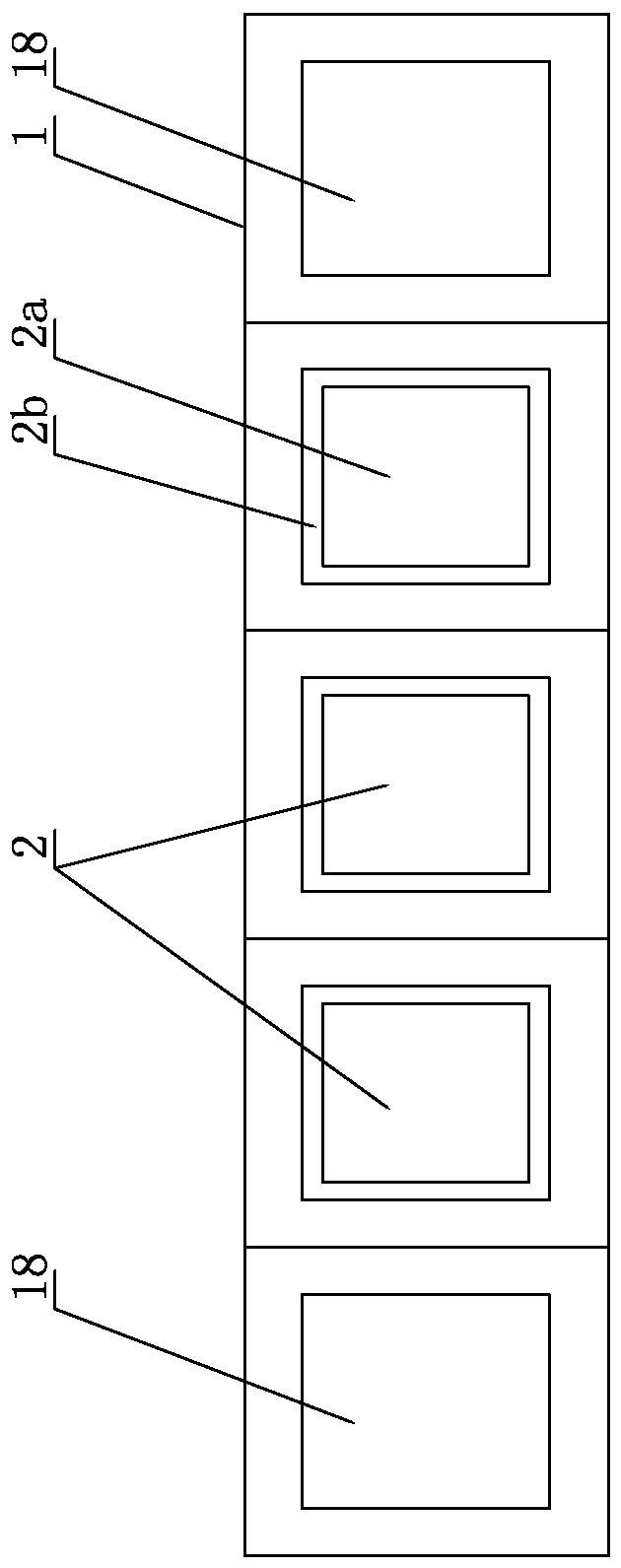

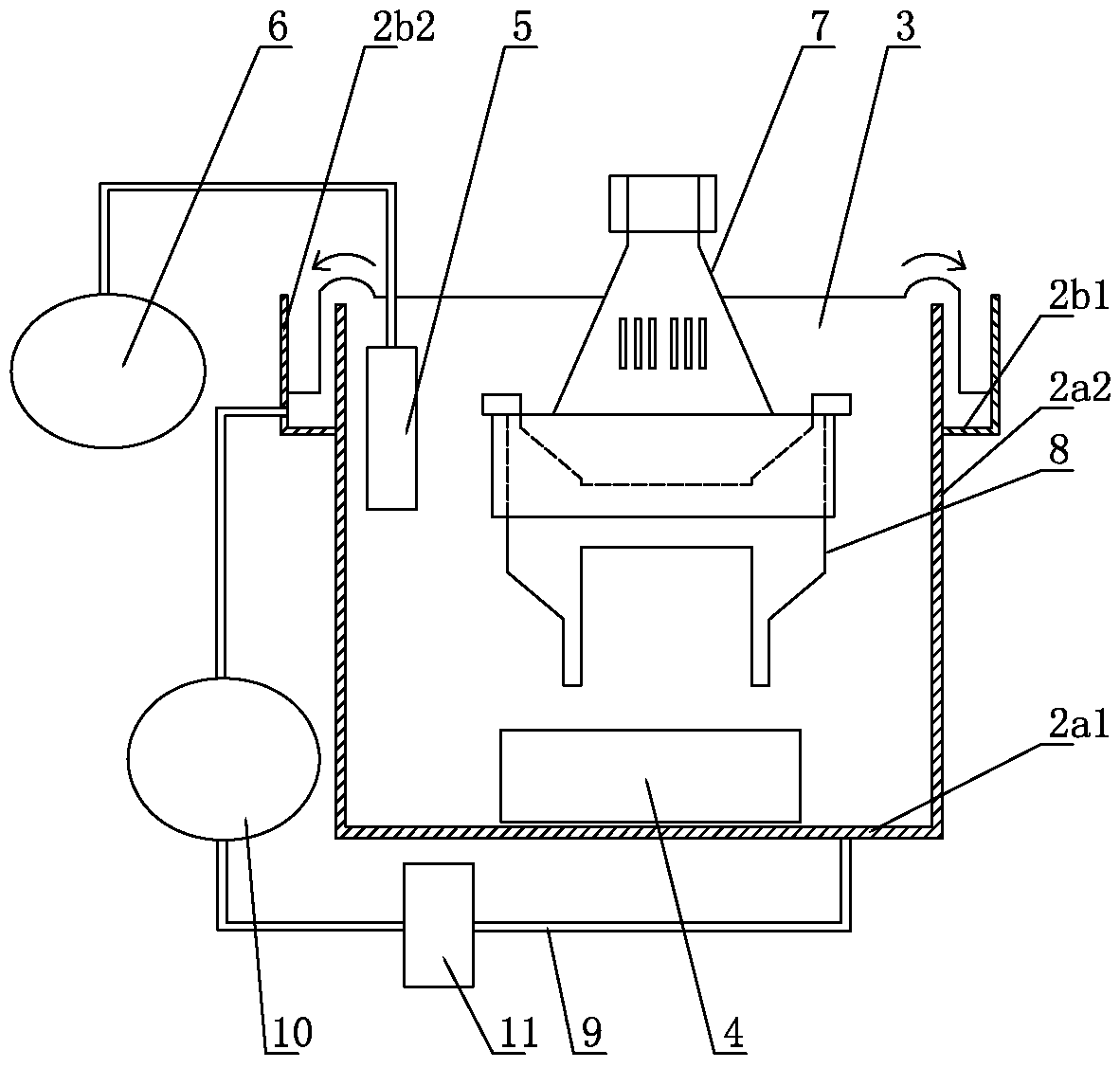

[0037] Such as Figure 1-11 , is a photoresist removing device for an integrated circuit chip, comprising a machine 1, on which a plurality of photoresist removing tanks 2 are arranged in sequence, and each photoresist removing tank 2 includes an inner tank 2a and an outer tank body 2b, the outer tank body 2b is located on the outer periphery of the inner tank body 2a, and the inner tank body 2a is filled with a photoresist removal liquid 3 that can overflow into the outer tank body 2b, and the main formula of the photoresist removal liquid 3 is "nitromethylpyrrolidone , sulfones (such as dimethyl sulfoxide), alcohols (2-aminoethanol), amines (such as ethanolamine), alkalis (such as tetramethylammonium hydroxide)" one or more of them; An ultrasonic generator 4 is arranged in the tank body 2a, and a heating device 5 is also arranged in the inner tank body 2a. The heating device 5 is electrically connected to the temperature control system 6, and a liftable wafer carrier 7 is pl...

Embodiment 2

[0049] Such as Figure 1-11 , is a photoresist removing device for an integrated circuit chip, comprising a machine 1, on which a plurality of photoresist removing tanks 2 are arranged in sequence, and each photoresist removing tank 2 includes an inner tank 2a and an outer tank body 2b, the outer tank body 2b is located on the outer periphery of the inner tank body 2a, the inner tank body 2a contains a photoresist liquid 3 that can overflow into the outer tank body 2b, the inner tank body 2a is provided with an ultrasonic generator 4, and the inner tank body 2a A heating device 5 is also provided in the tank body 2a, and the heating device 5 is electrically connected to the temperature control system 6. A liftable wafer carrier 7 is placed in the inner tank body 2a, and a wafer boat 8 is positioned on the wafer carrier 7 , a number of parallel wafers are vertically placed in the crystal boat 8; the outer tank 2b is connected to the bottom of the inner tank 2a through an extern...

Embodiment 3

[0060] Such as Figure 1-11 , is a photoresist removing device for an integrated circuit chip, comprising a machine 1, on which a plurality of photoresist removing tanks 2 are arranged in sequence, and each photoresist removing tank 2 includes an inner tank 2a and an outer tank body 2b, the outer tank body 2b is located on the outer periphery of the inner tank body 2a, the inner tank body 2a contains a photoresist liquid 3 that can overflow into the outer tank body 2b, the inner tank body 2a is provided with an ultrasonic generator 4, and the inner tank body 2a A heating device 5 is also provided in the tank body 2a, and the heating device 5 is electrically connected to the temperature control system 6. A liftable wafer carrier 7 is placed in the inner tank body 2a, and a wafer boat 8 is positioned on the wafer carrier 7 , a number of parallel wafers are vertically placed in the crystal boat 8; the outer tank 2b is connected to the bottom of the inner tank 2a through an extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com