Nacelle cover of wind turbine and processing method thereof

A technology for wind turbines and nacelle covers, which is applied in wind power generation, wind turbines, machines/engines, etc., can solve the problems of time-consuming and labor-intensive laying of reinforcing ribs, quality defects of resin-rich, difficult processing, etc., so as to save production time and Labor, saving labor and time costs, and the effect of not easy resin accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

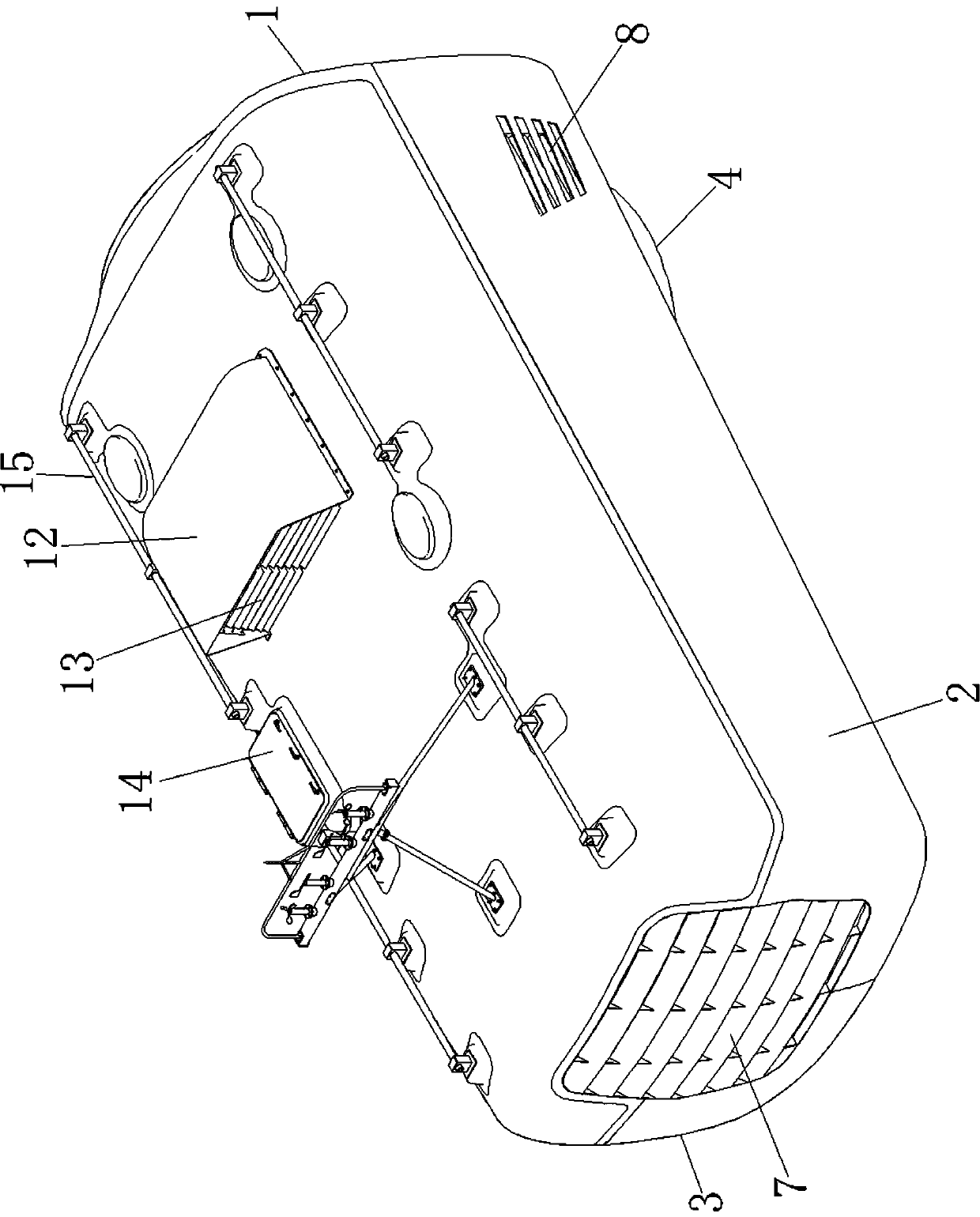

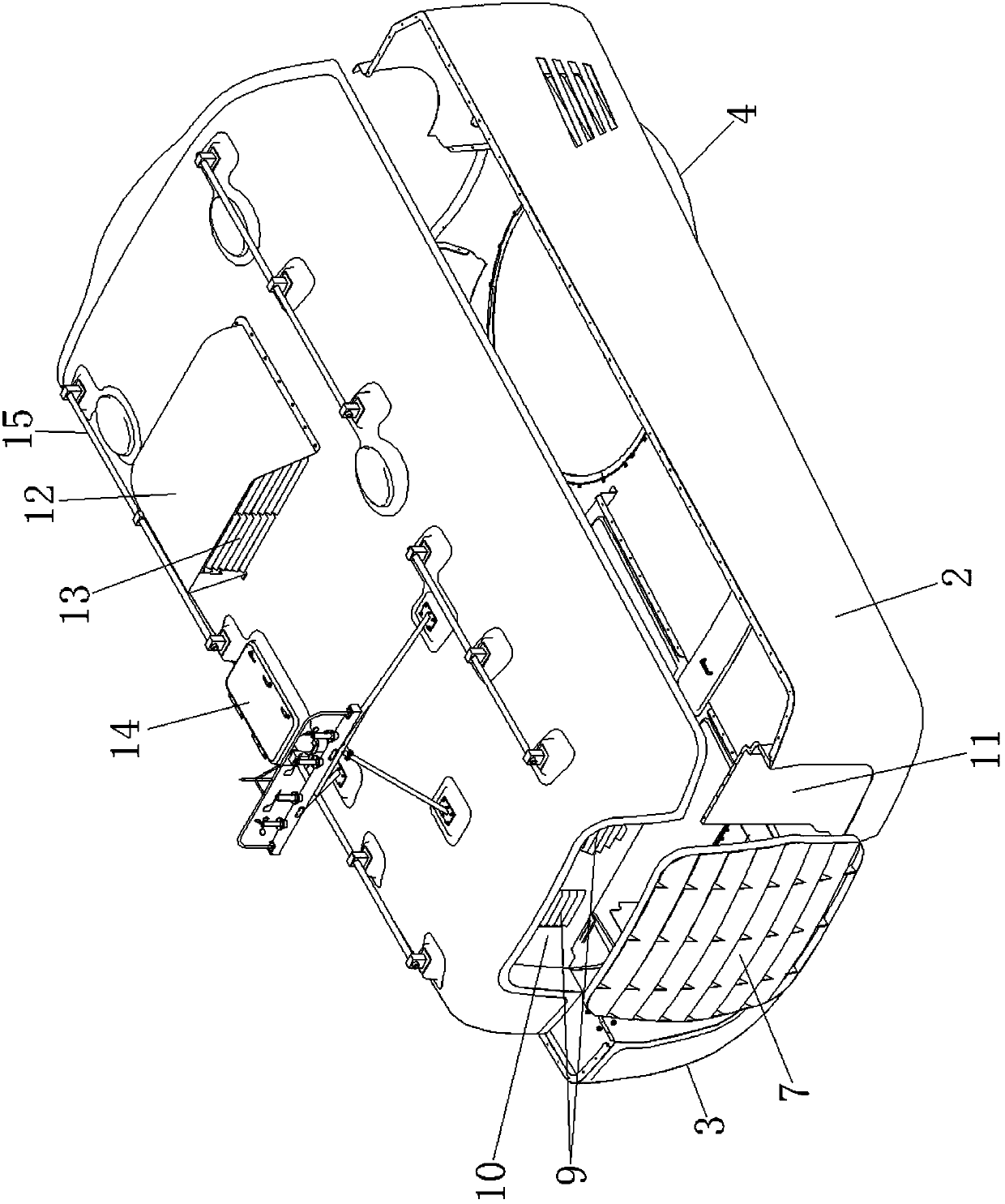

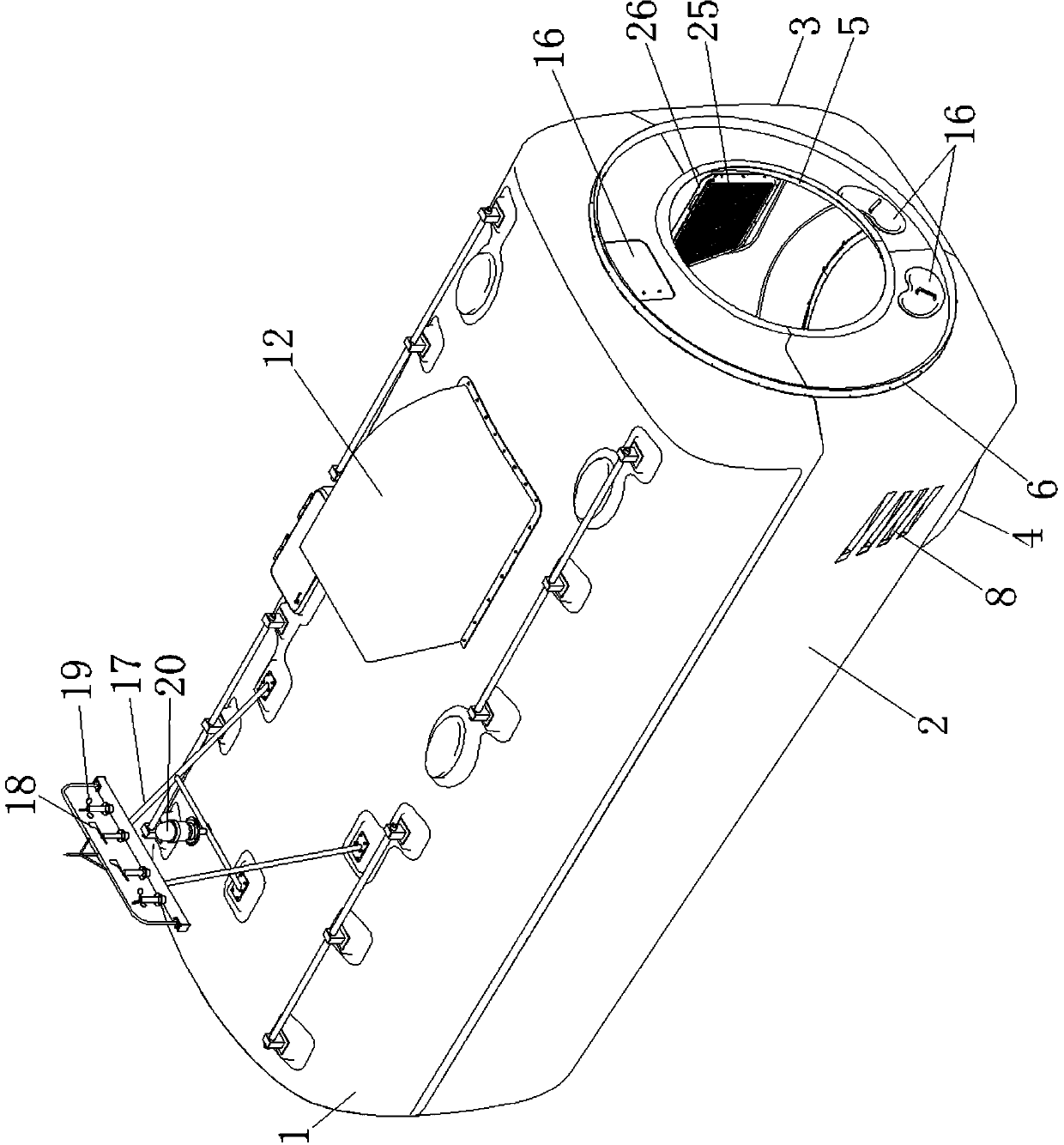

[0024] Such as Figure 1-4 As shown, a nacelle cover of a wind turbine includes a nacelle body. The front end of the nacelle body is provided with a rotor locking disk 5, and the bottom end of the front part of the nacelle body is provided with a tower installation port 4. The nacelle body includes The left engine room lower body 3, the right engine room lower body 2 connected to the right side of the left engine room lower body 3 by bolts and the engine room upper cover 1 connected to the right engine room lower body 2 and the left engine room lower body 3 by bolts, the left engine room lower body 3, and the right engine room lower body 2 And the cabin loam cake 1 is all made of the PVC outline plate 21 that is provided with some through holes, the inner glass steel layer 22 that is formed on the inner layer of the PVC outline plate 21, the outer glass fiber reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com