Novel hoisting equipment with weighing sensors, and weighing method

A lifting equipment and weighing sensing technology, which is applied in the directions of cranes, hoists, and hoisting devices of trolleys, can solve problems such as inability to provide auxiliary measurement solutions, measurement results of reel displacement and weighing, and changes in mechanical properties of strain gauges. , to achieve the effect of improving data accuracy, eliminating potential safety hazards, and tightening the limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

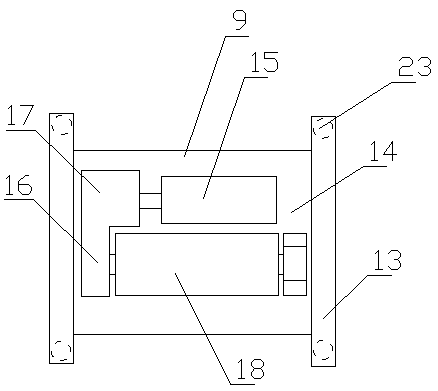

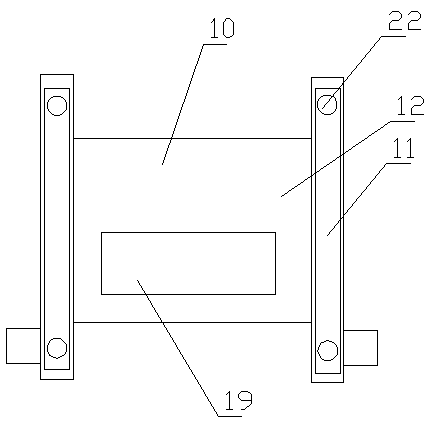

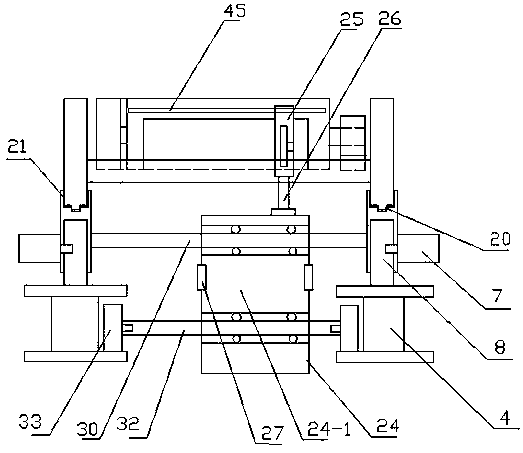

[0044] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0045] Such as Figure 1 to Figure 8 As described above, a new type of lifting equipment provided with a weighing sensor device according to the present invention includes a crane walking track 1, a bridge frame 2 and a lifting trolley 3, and the bridge frame 2 includes two sets of main girders 4 and two sets of end girders 5. The two sets of end beams 5 are respectively arranged on the crane running track 1 on both sides, and the bridge frame 2 is driven by the driving device of the cart to run along the length direction of the running track 1 of the crane. , speed reducer 16, wheel 8 and brake constitute. The two groups of main girders 4 are provided with a lifting trolley 3, and the lifting trolley 3 is driven by the trolley driving device to move along the length direction of the two groups of main girders 4. The trolley driving device is mainly composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com