An automatic tape roll cutting machine

A tape roll and cutting machine technology, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of labor occupation, low degree of automation, and low production efficiency, so as to reduce work intensity and improve production High efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

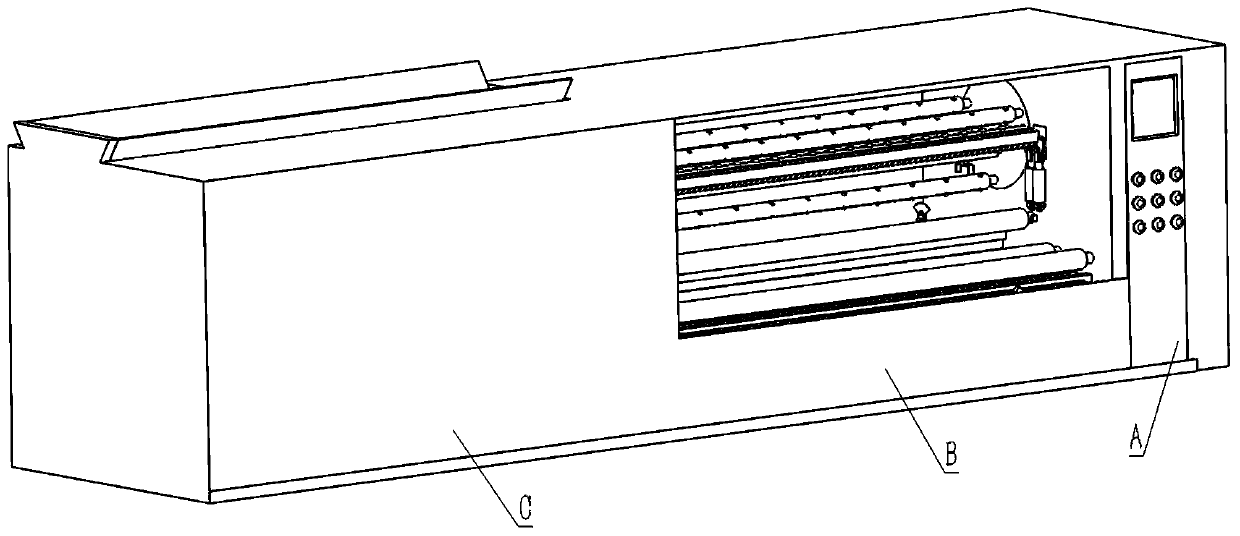

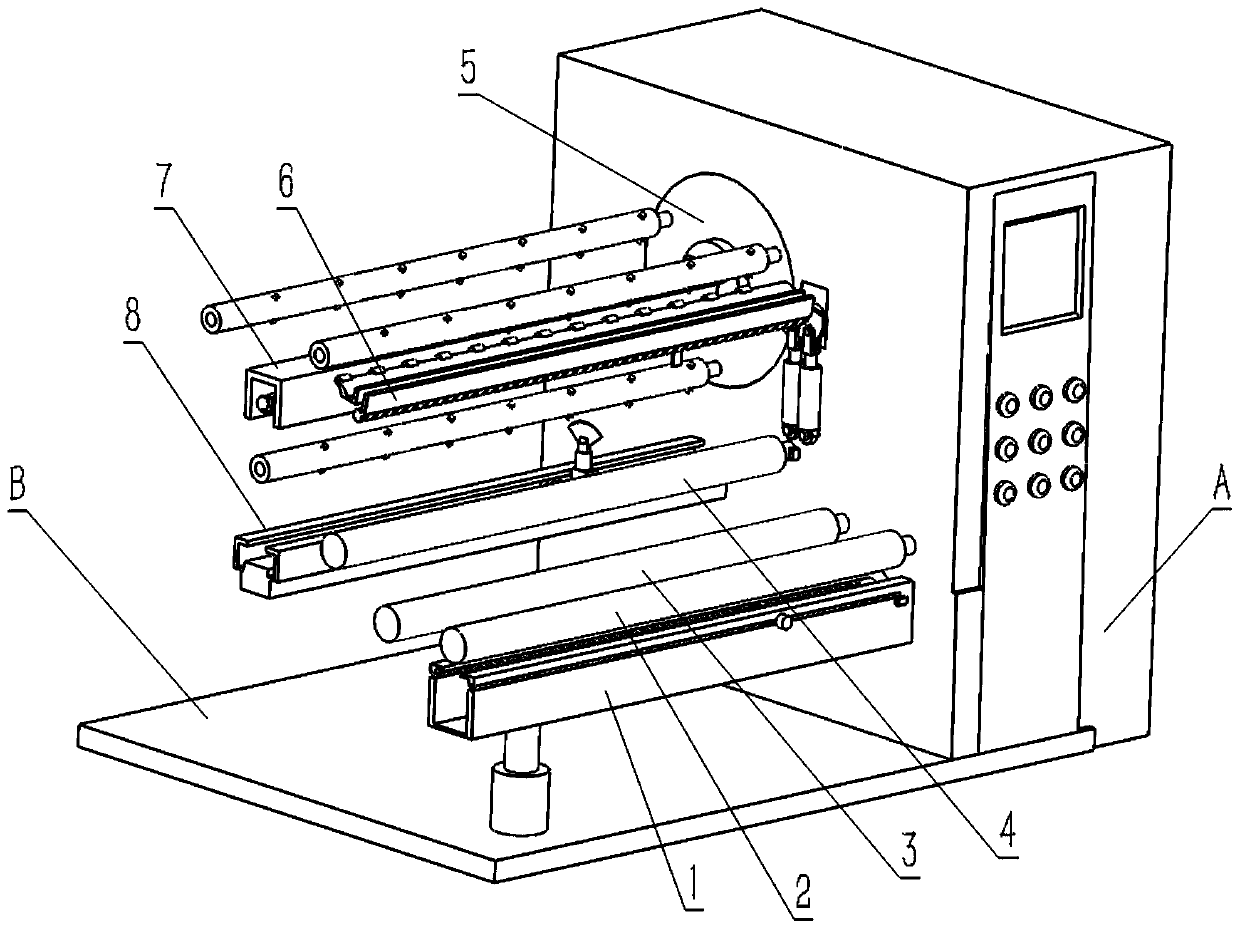

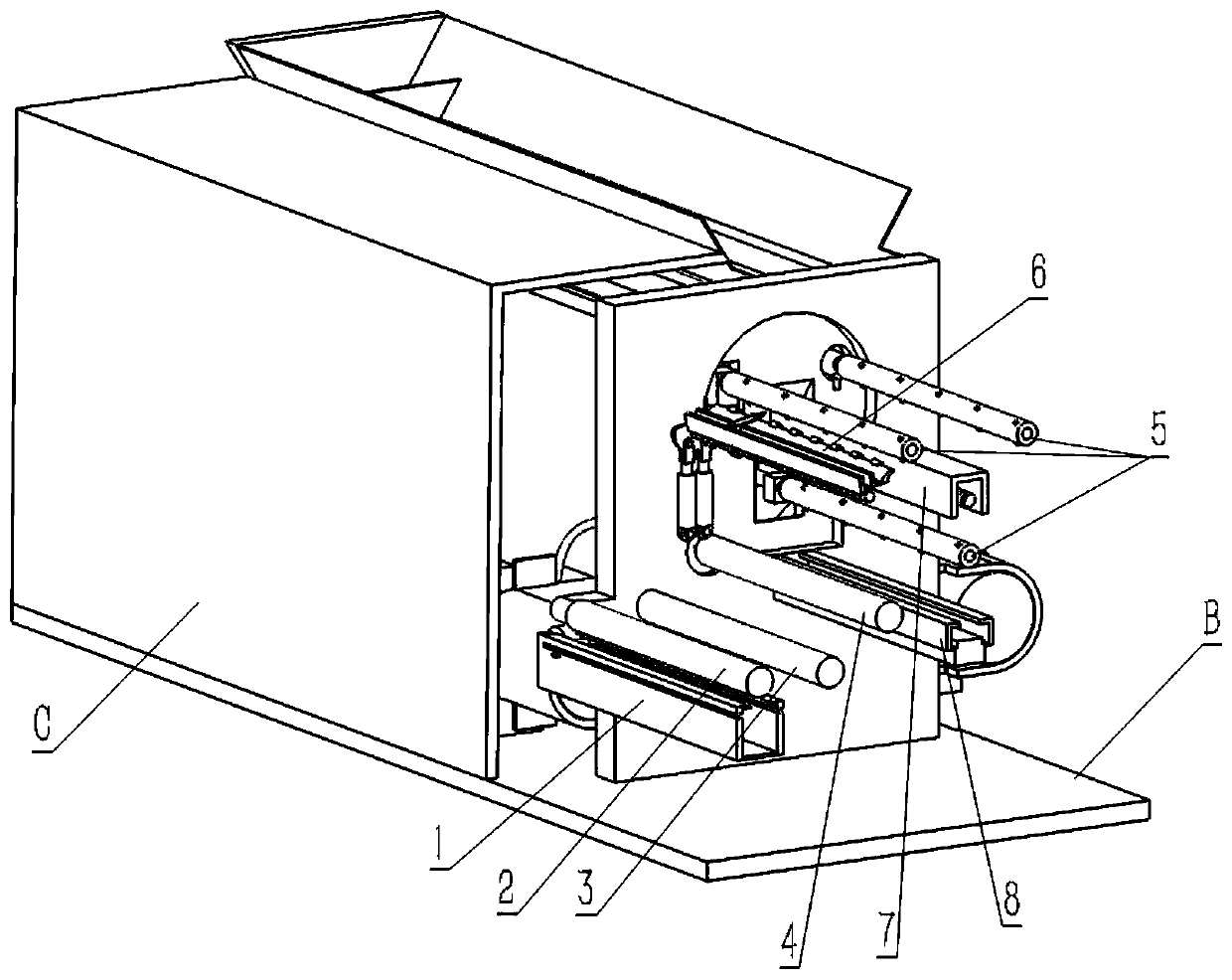

[0033] Such as Figure 1 to Figure 17 As shown, a kind of automatic adhesive tape coiling and cutting machine of the present invention adopts the technical scheme that includes an electromechanical installation control area A, a coiling and cutting processing area B, and a loading and unloading area C, and is characterized in that: the coiling and cutting processing area B The right side is the electromechanical installation control area A, the left side is the loading and unloading area C, the joint device 1 is installed on the front end floor of the coiling processing area B, and the first tension shaft 2 is installed directly above the joint device 1 A second tension shaft 3 is installed at the same height as the first tension shaft 2 and parallel to it, and a third tension shaft 4 is installed parallel to it above the second tension shaft 3, and the two ends of the third tension shaft 4 are installed There is a tension sensor 18, and a three-station tape roll device 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com