Wire Harness Anti-Termite Tube Installation Device

An installation device and anti-termite technology, which is applied in the direction of cable installation device, manufacturing wiring harness, cable installation, etc., can solve the problems of poor positioning accuracy, low work efficiency, easy oxidation, corrosion and other problems of the bushing, and achieve the realization of set and height adjustment The effect of processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

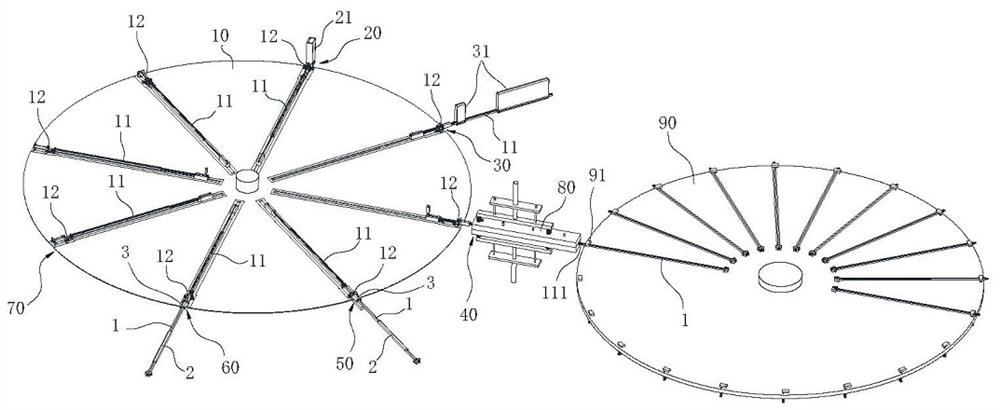

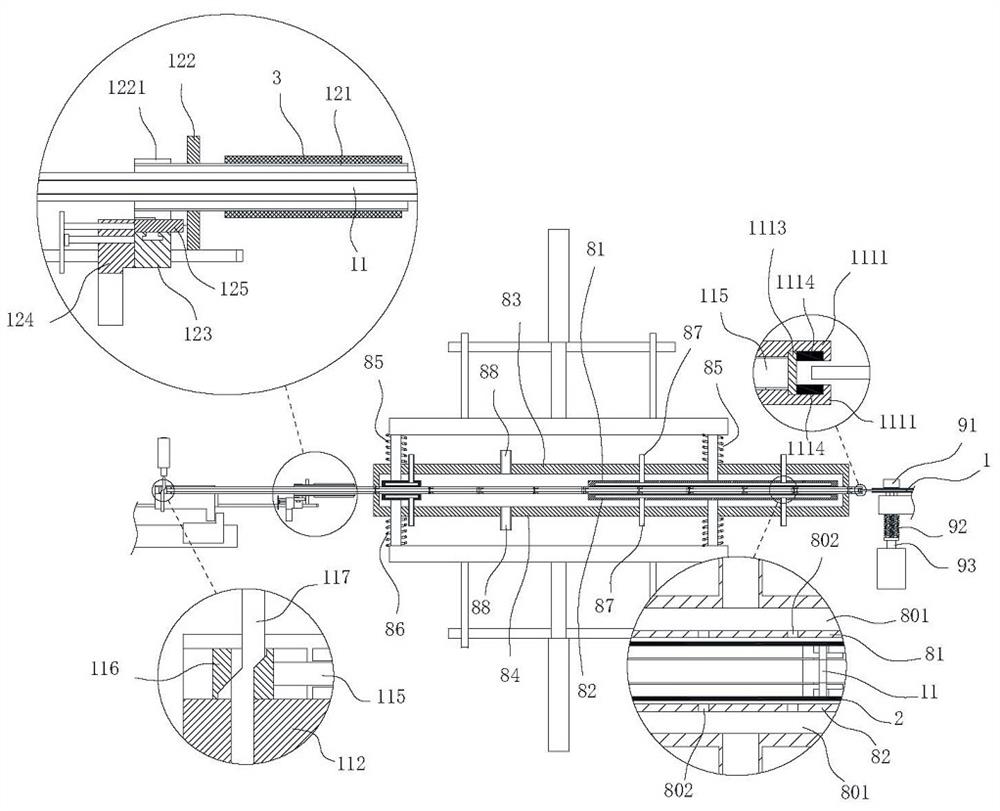

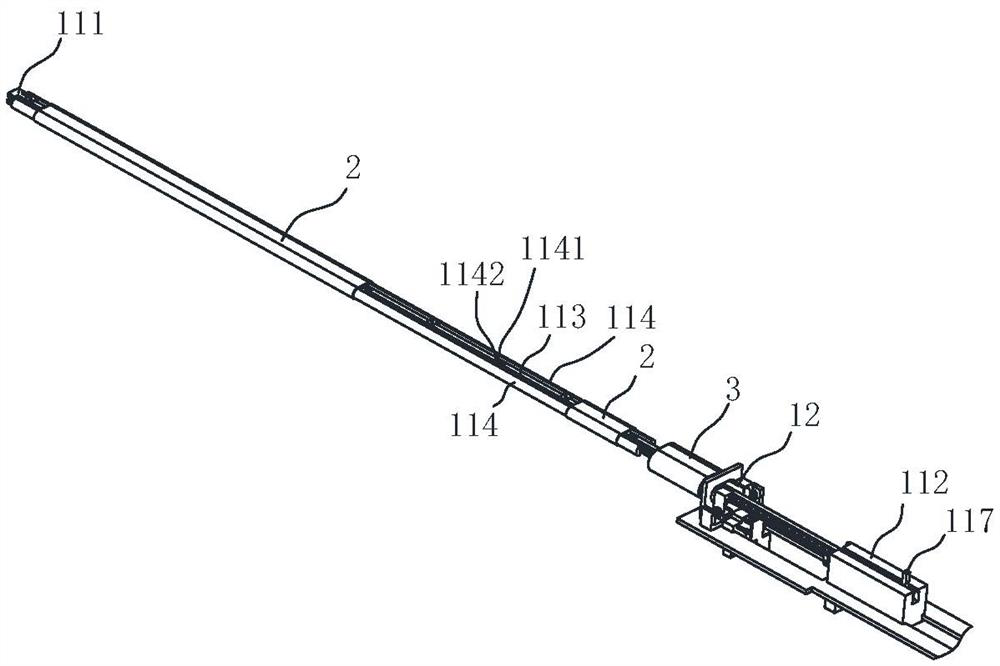

[0034] like figure 1As shown, a wire harness processing system includes a transfer mechanism 10. The transfer mechanism 10 is provided with a rod-shaped mechanical arm 11 and a pipe-supporting manipulator 12; One end of the rod-shaped manipulator 11 is provided with a gripper 111, and the sliding path of the rod-shaped manipulator 11 is arranged through the pipe-supporting manipulator 12; the transfer path of the transfer mechanism 10 is sequentially provided with a pipe-releasing station 20 and a pipe-arranging station 30 , the set station 40, the withdrawal station 50, the unloading station 60 and the reset station 70; the pipe release station 20 is provided with a pipe release mechanism, and the pipe release mechanism is used to set the anti-ant pipe 3 on the support pipe. on the manipulator 12; the pipe arranging station 30 is provided with a pipe arranging mechanism, and the pipe arranging mechanism is used to fit the heat shrinkable tube 2 on the rod-shaped mechanical ar...

Embodiment 2

[0057] A wire harness prepared by the following method:

[0058] Step 1: Cut the wire 1 to a preset length, and peel off both ends of the wire 1 to leak out the core;

[0059] Step 2: Install a terminal on one end of wire 1;

[0060] Step 3: Put the heat shrinkable tube 2 on the wire 1 from the other end of the wire 1, adjust the heat shrinkable tube 2 to the preset position, and heat the heat shrinkable tube 2 to wrap it on the wire 1;

[0061] Step 4: Set the anti-termite tube 3 to the preset position on the wire 1 from the end described in Step 3, and the wire harness is completed;

[0062] In the steps 3 and 4, the heat shrinkable tube 2 and the anti-termite tube 3 are assembled using the wire harness processing system described in Embodiment 1.

Embodiment 3

[0064] A method of using the processing system described in Embodiment 1 to set the heat shrinkable tube 2, comprising the following steps:

[0065] Step 1: Set the heat shrinkable tube 2 on the rod-shaped mechanical arm 11 described in Example 1;

[0066] Step 2: Clamp the end of the wire 1 with the gripper 111 of the rod-shaped mechanical arm 11, and fix the heat shrinkable tube 2 with the tube fixing mechanism 80 shown in Embodiment 1;

[0067] Step 3: Pull the rod-shaped robotic arm 11, and pull the wire 1 into the heat shrinkable tube 2;

[0068] Step 4: Heat the heat shrinkable tube 2 to wrap it on the wire 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com