A rubber ring installation mechanism for an RO machine filter element

A technology of installation mechanism and rubber ring, applied in the direction of membrane technology, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of low efficiency and waste of labor, and achieve the effect of high efficiency and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

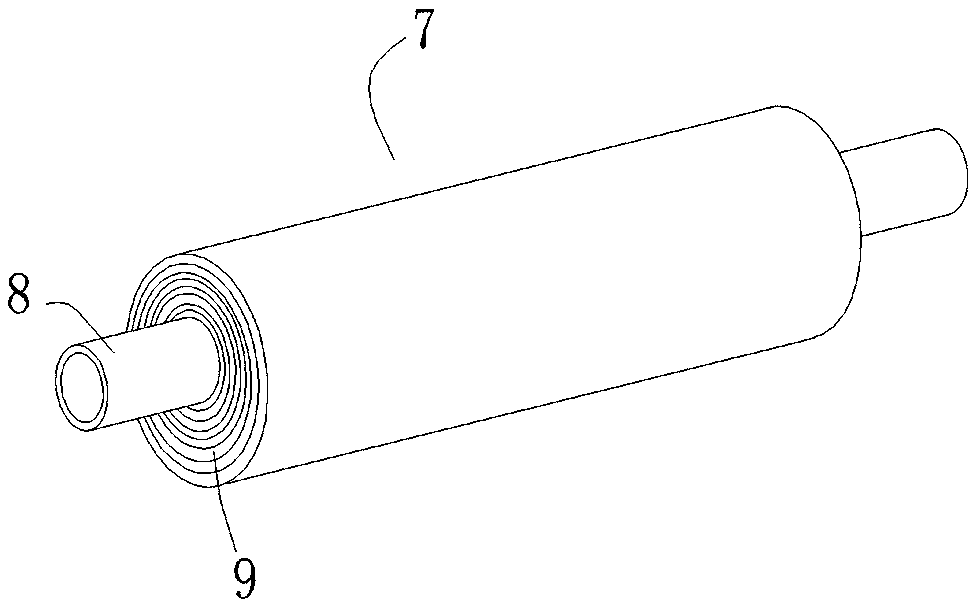

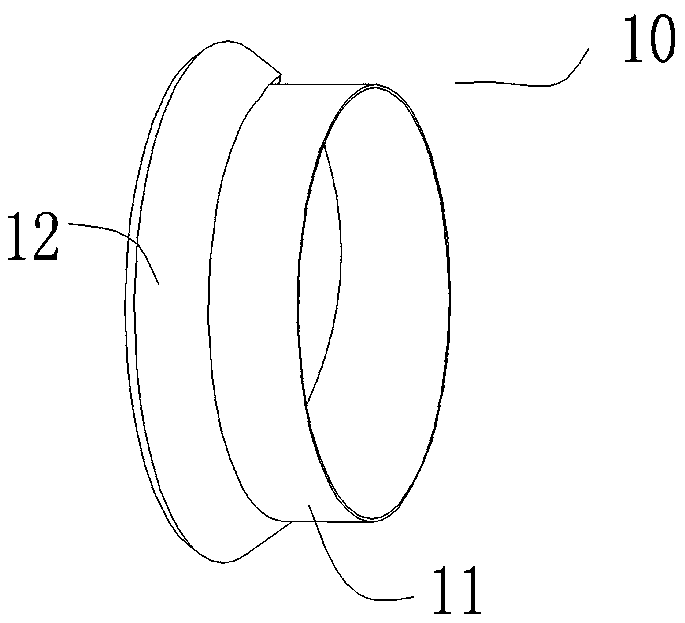

[0044] refer to Figure 1~Figure 10 , the RO machine filter element 7 includes a hollow central shaft cylinder 8. When making the RO machine filter element, the filter membrane 9 is wound on the central axis cylinder 8 layer by layer, and then the wound filter membranes at both ends are cut off to Ensure that the end face of the filter membrane is smooth, and the central shaft cylinder 8 at both ends is exposed. During assembly, a rubber ring 10 needs to be put on one end of the remaining filter membrane. One end of the rubber ring 10 is a cylinder 11 and the other end is an enlarged part 12 .

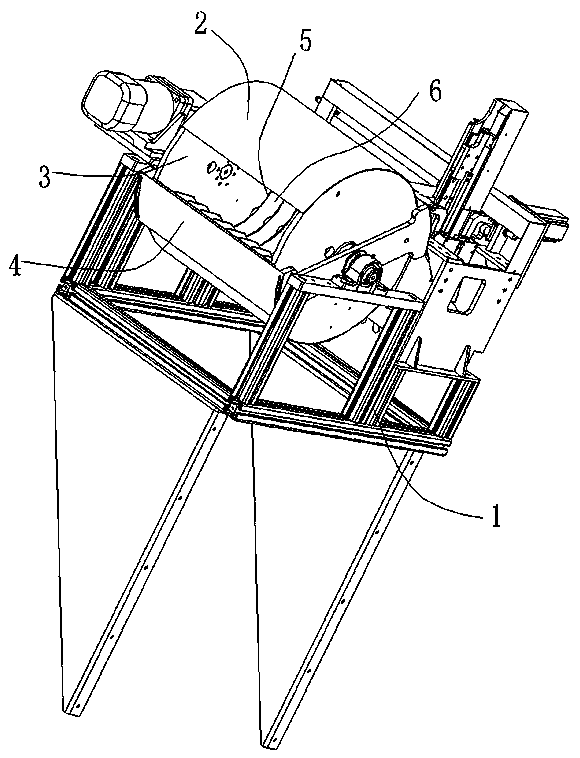

[0045] A rubber ring installation mechanism of an RO machine filter element includes a rubber ring storage mechanism, a rubber ring delivery mechanism, and a rubber ring assembly mechanism.

[0046] The rubber ring storage mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com