Circulating recycling device for adhesive solvent

A solvent circulation and transmission pipeline technology, applied in filtration loops, filtration separation, separation methods, etc., can solve the problems of affecting production efficiency, low filtration efficiency, slow recovery speed, etc., to increase production efficiency, simple structure, and remove odors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

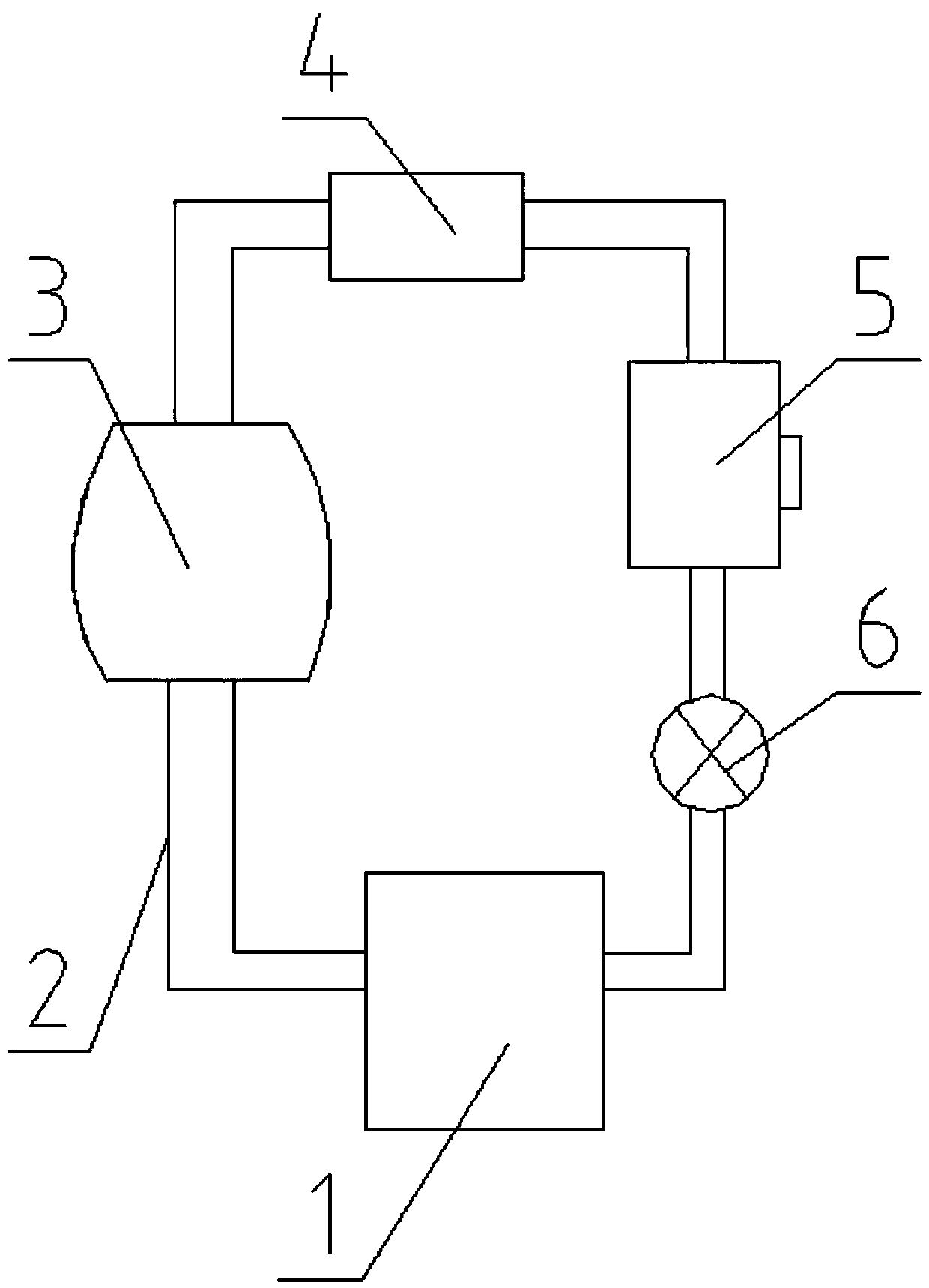

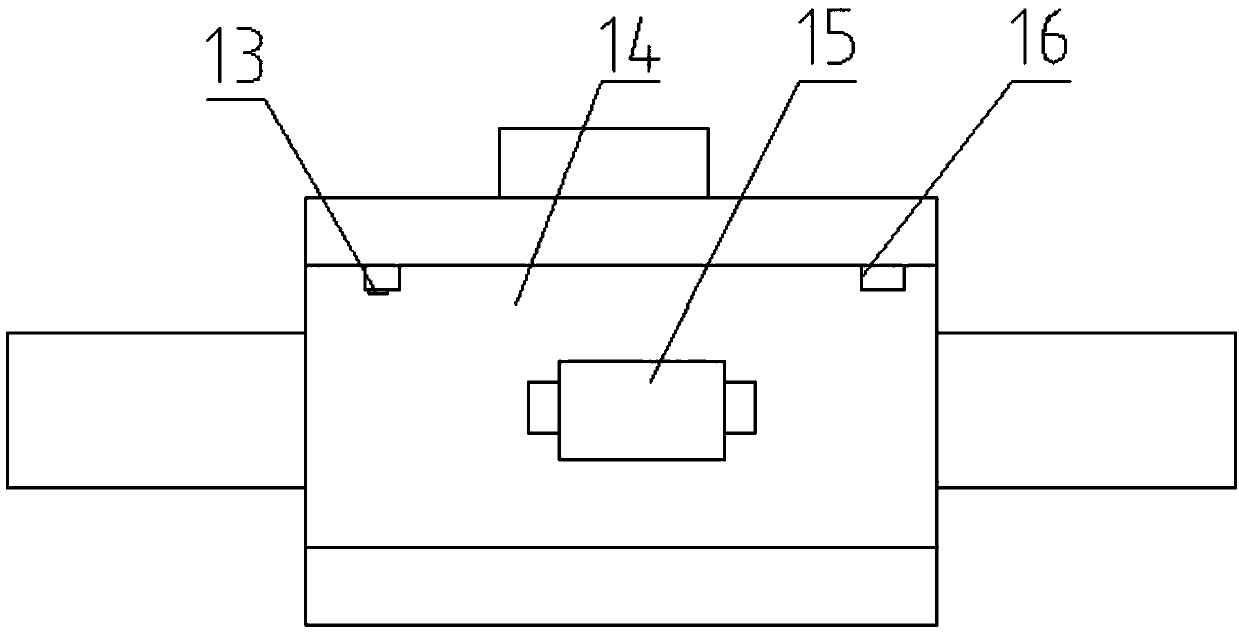

[0021] Such as Figure 1-Figure 4 As shown, an adhesive solvent recycling device includes a liquid collection bucket 1, a transmission pipeline 2, a filter 3, a cooler 4, a heater 5, a drive pump 6, a cooling pipe 8, a heating resistor 15, and a filter plate 10, The two ends of the liquid collection barrel 1 are provided with transmission pipes 2, the liquid collection barrel 1 is used to collect waste liquid and store solvent, the transmission pipe 2 is used to transmit solvent liquid, and the transmission pipe 2 is provided with a filter 3, and the filter 3 is used for filtering Solvent, the inside of the filter 3 is provided with a filter plate 10, the filter plate 10 is used to initially filter large particles, the filter plate 10 is provided with a filter hole 9, the filter hole 9 is used for solvent discharge, and the bottom of the filter plate 10 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com