A heat pump dishwasher and its control method

A dishwasher and heat pump technology, which is applied in the field of heat pump dishwashers and controls, can solve the problems of slow temperature return and energy waste, and achieve the effects of fast cooling, good heat exchange effect, and prevention of pooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

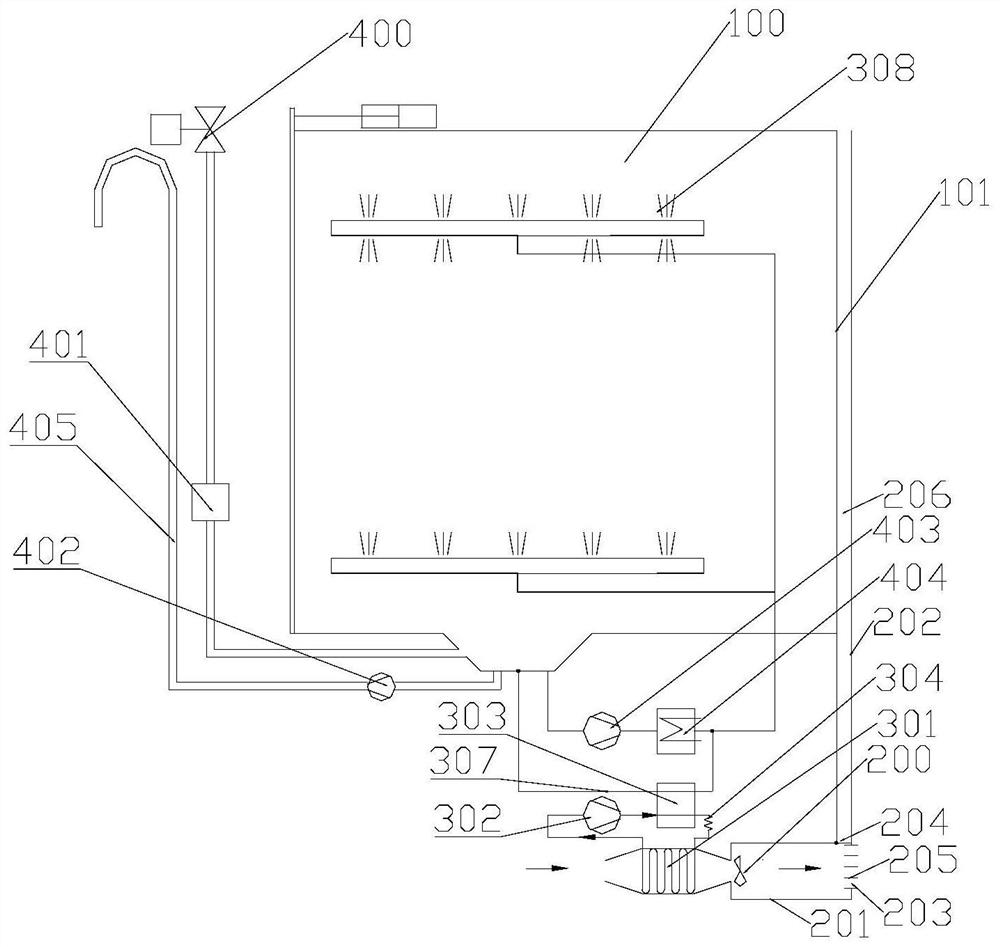

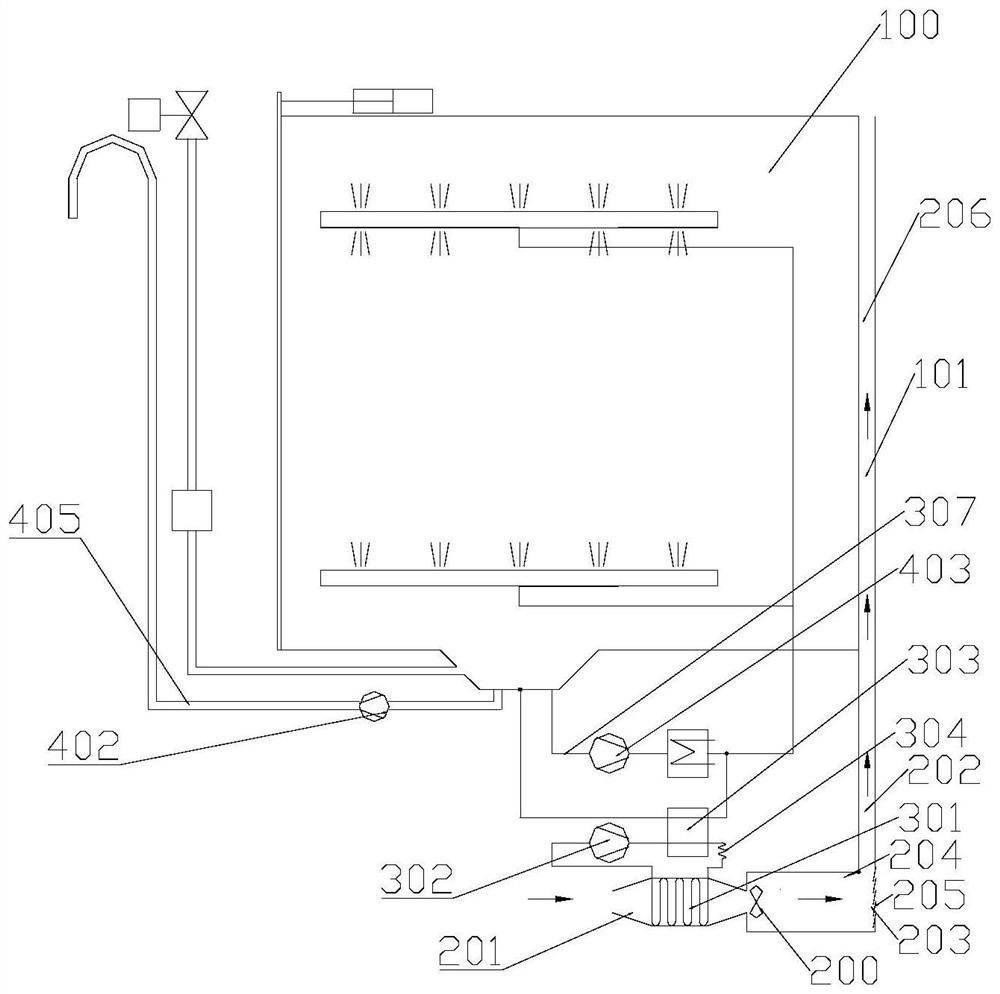

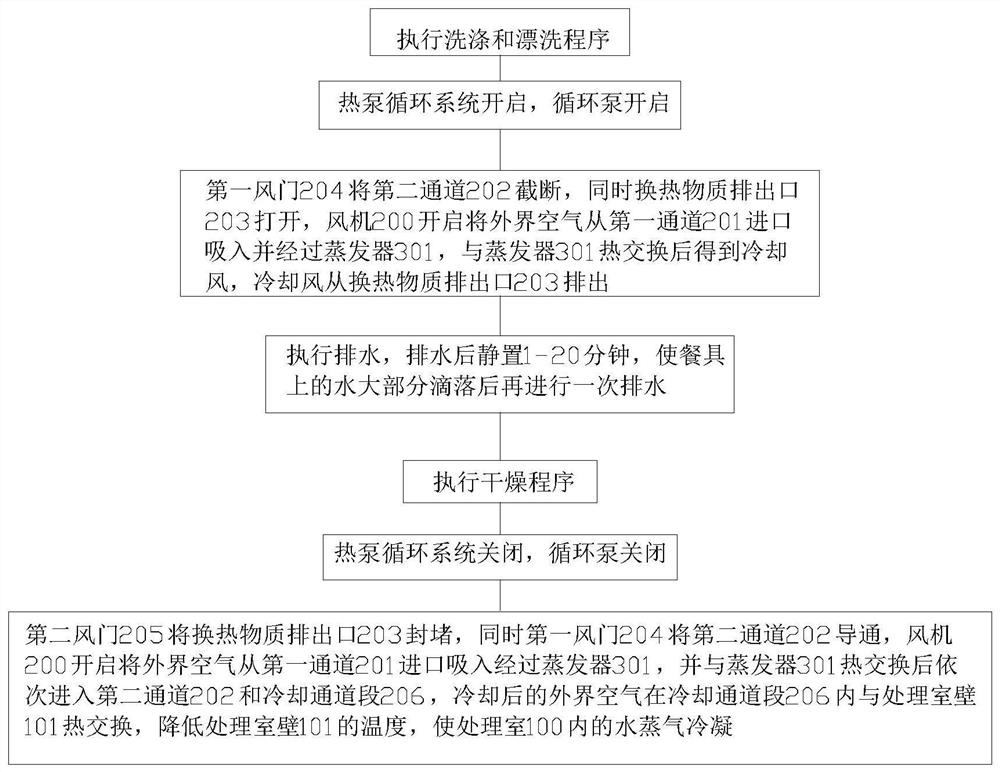

[0044] Such as Figure 1-2 As shown, a dishwasher includes a processing chamber 100 for washing dishes with washing water, a cooling device 301, and a cooling system, and the cooling system carries a heat exchange material and cools the processing chamber wall 101 after being cooled by the cooling device 301, so that The water vapor in the processing chamber 100 condenses on the processing chamber wall 101 to realize the drying of the tableware.

[0045] By setting up a cooling system, the cooling system carries the heat exchange material through the cooling device, and uses the cooling function of the cooling device 301 to cool down the heat exchange material passing through the cooling device 301, and the cooled heat exchange material exchanges heat with the processing chamber wall 101, The temperature of the heat-exchanging substance rises, the temperature of the processing chamber wall 101 decreases, and the water vapor in the cooling chamber encounters the lower temperatu...

Embodiment 2

[0048] Such as Figure 1-2 As shown, this embodiment is a further limitation of Embodiment 1. The dishwasher also includes a heat pump cycle system. The heat pump cycle system includes a compressor 302, a condenser 303, a throttling device 304, and an evaporator 301. The compressor 302, condenser The device 303, the throttling device 304 and the evaporator 301 are connected to each other to form a refrigerant circuit. The cooling device 301 is an evaporator 301 of a heat pump cycle system. The cooling system carries a heat exchange substance through the evaporator 301 , and the heat exchange substance cools down the temperature of the processing chamber wall 101 after being cooled by the evaporator 301 .

[0049] The compressor 302 is turned on, the cooling system carries the heat exchange material through the evaporator 301, the refrigerant absorbs the energy of the heat exchange material outside the evaporator 301 and evaporates itself, so that the temperature of the heat ex...

Embodiment 3

[0085] Such as Figure 1-2 As shown, this embodiment is a specific implementation of Embodiment 1 and Embodiment 2. A dishwasher includes a door body 103, a body 102, a drainage system, a spray system, a heat pump circulation system and a cooling system. A processing chamber 100 is provided in the body, and the processing chamber includes a coverable body and a cover, and the body and the cover are closed to form a closed processing chamber. The washing water enters the treatment chamber 100 through a water inlet pipeline, on which a water inlet valve 400 and a respirator 401 are arranged. The user opens the door body and places the tableware to be washed into the processing chamber 100 through the opening. According to needs, a shelving basket or a shelving rack may also be provided in the processing chamber 100, and the tableware is placed on the shelving basket or the shelving rack.

[0086] A circulating water channel 307 is provided at the bottom of the dishwasher, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com