Etching equipment using inkjet printing

An etching equipment and inkjet printing technology, which is applied in chemical/electrolytic methods to remove conductive materials, electrical components, circuits, etc., can solve the problems of insufficient image quality, inability to achieve image quality, poor retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] see Figure 1-Figure 6 , the present invention provides etching equipment using inkjet printing, its structure includes a cover 1, a casing 2, and an etching device 3, the cover 1 is arranged on the casing 2 and is movably connected with the casing 2 through a hinge, and the etching device 3 is installed in the housing 2;

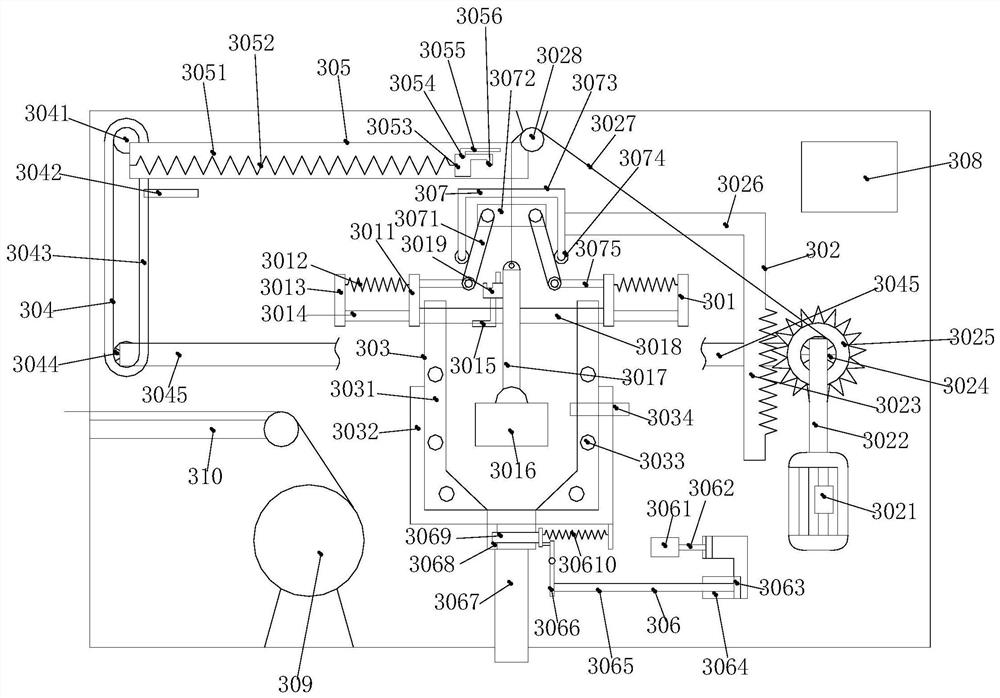

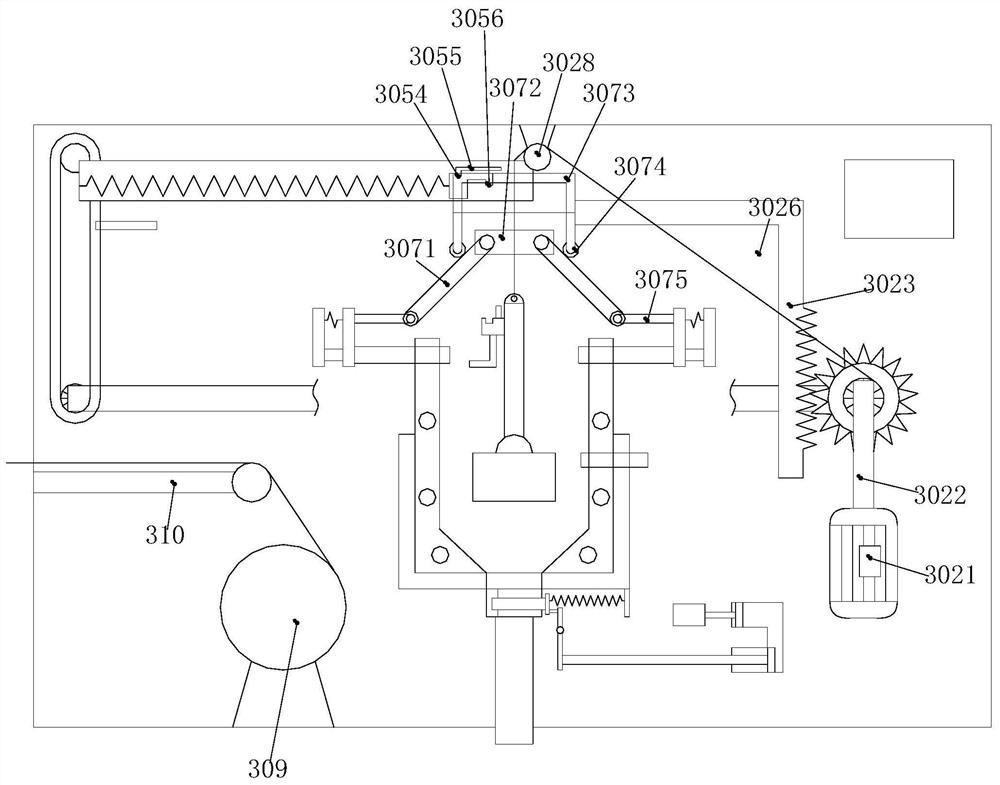

[0030] The etching device 3 is composed of a movable door mechanism 301, a drive mechanism 302, a heating mechanism 303, a mechanical transmission mechanism 304, a translation mechanism 305, a liquid discharge mechanism 306, a movable door control mechanism 307, a circuit board 308, a paper bundle 309, an etching table 310 composition;

[0031] The movable door panel mechanism 301 is mechanically cooperated with the movable door panel control mechanism 307, the described driving mechanism 302 is mechanically cooperated with the mechanical transmission mechanism 304, the described mechanical transmission mechanism 304 is mechanically connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com