A production material management system and method

A technology of management system and management method, which is applied in the field of automatic production management, can solve the problems of improving efficiency and reducing costs in the manufacturing industry, losing batch data, and wasting a lot of man-hours, etc., so as to improve traceability, improve accuracy, avoid confusing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

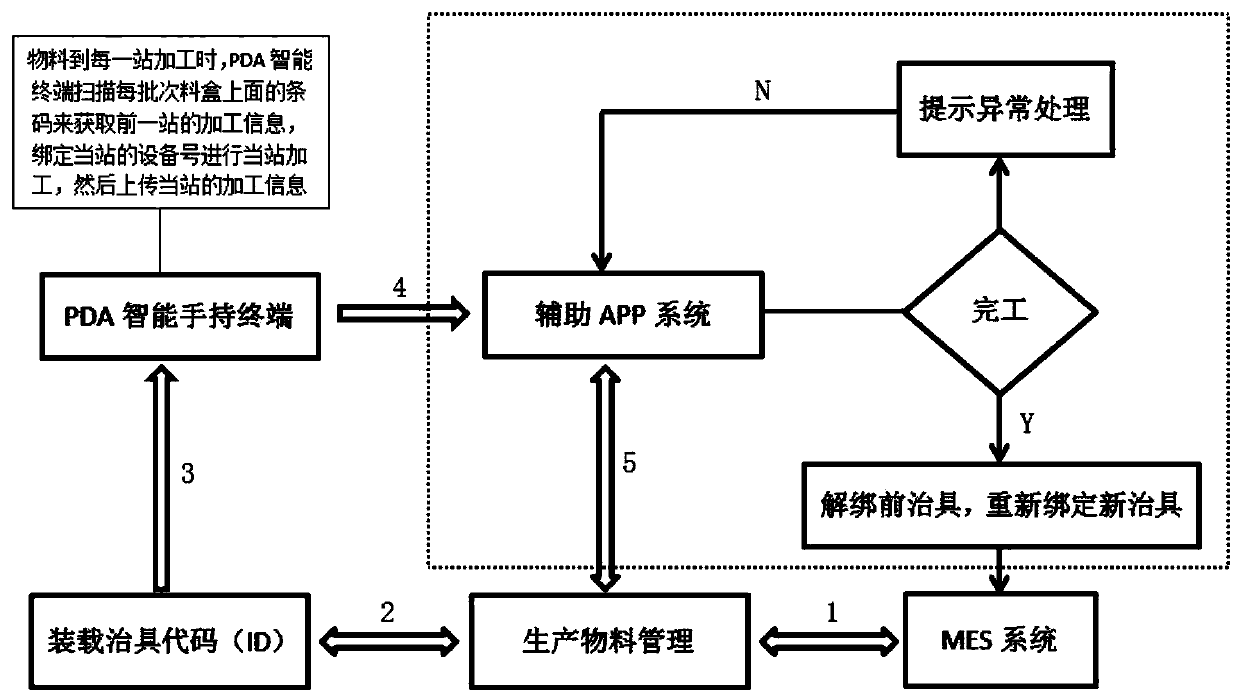

[0024] The invention provides a management system and method for production materials. Its working principle is to bind the jig when entering the station by assigning a unique code to the jig, and unbind the jig when leaving the station. Enter the processing information of the fixture at the current station to avoid confusion during material transfer, ensure data accuracy and traceability, and improve operational efficiency.

[0025] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

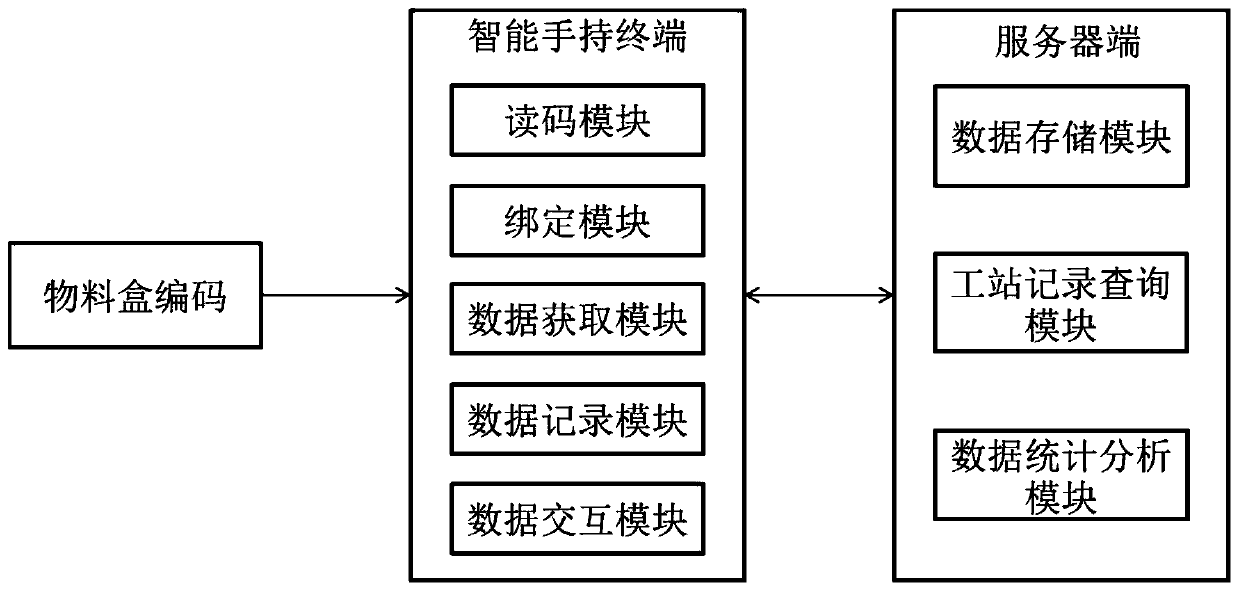

[0026] Such as figure 1 and figure 2 As shown, a management system for production materials, the system includes: a smart hand-held terminal, a server and a material box code, the smart hand-held terminal is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com