Wall construction device

A construction device and wall technology, applied in construction, building structure, construction material processing, etc., can solve problems affecting on-site construction, poor stability, poor safety, etc., to ensure construction quality, good stability, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

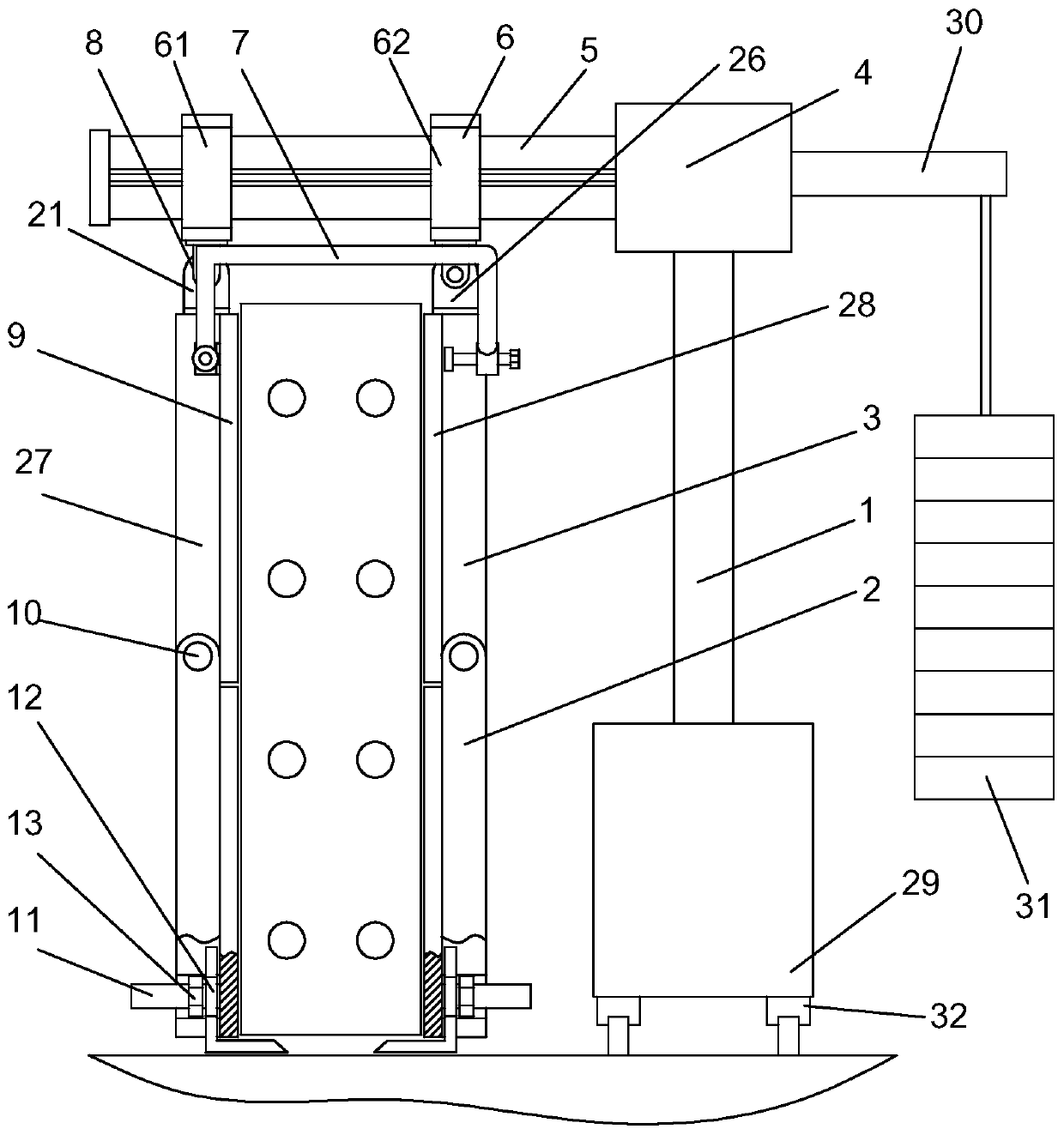

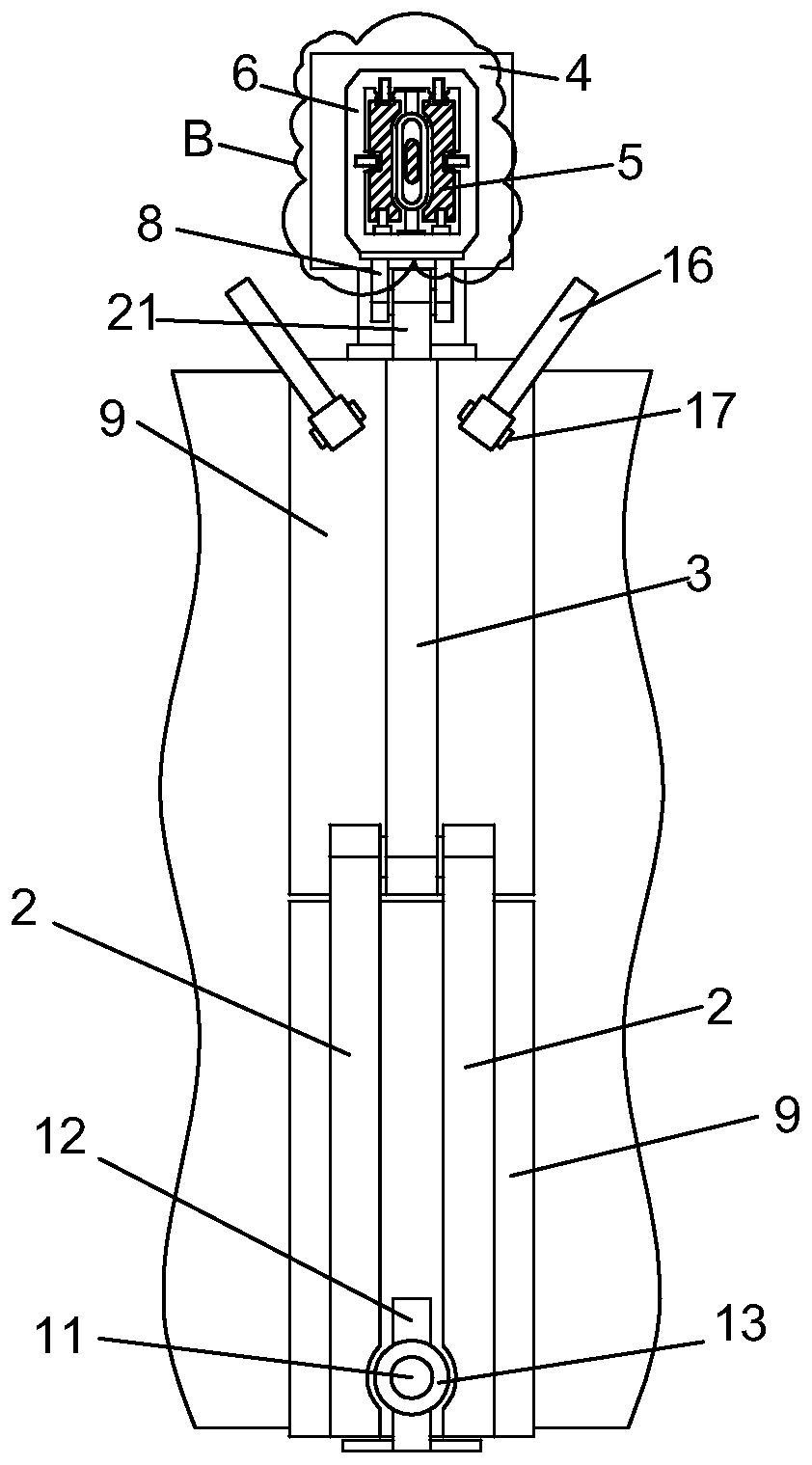

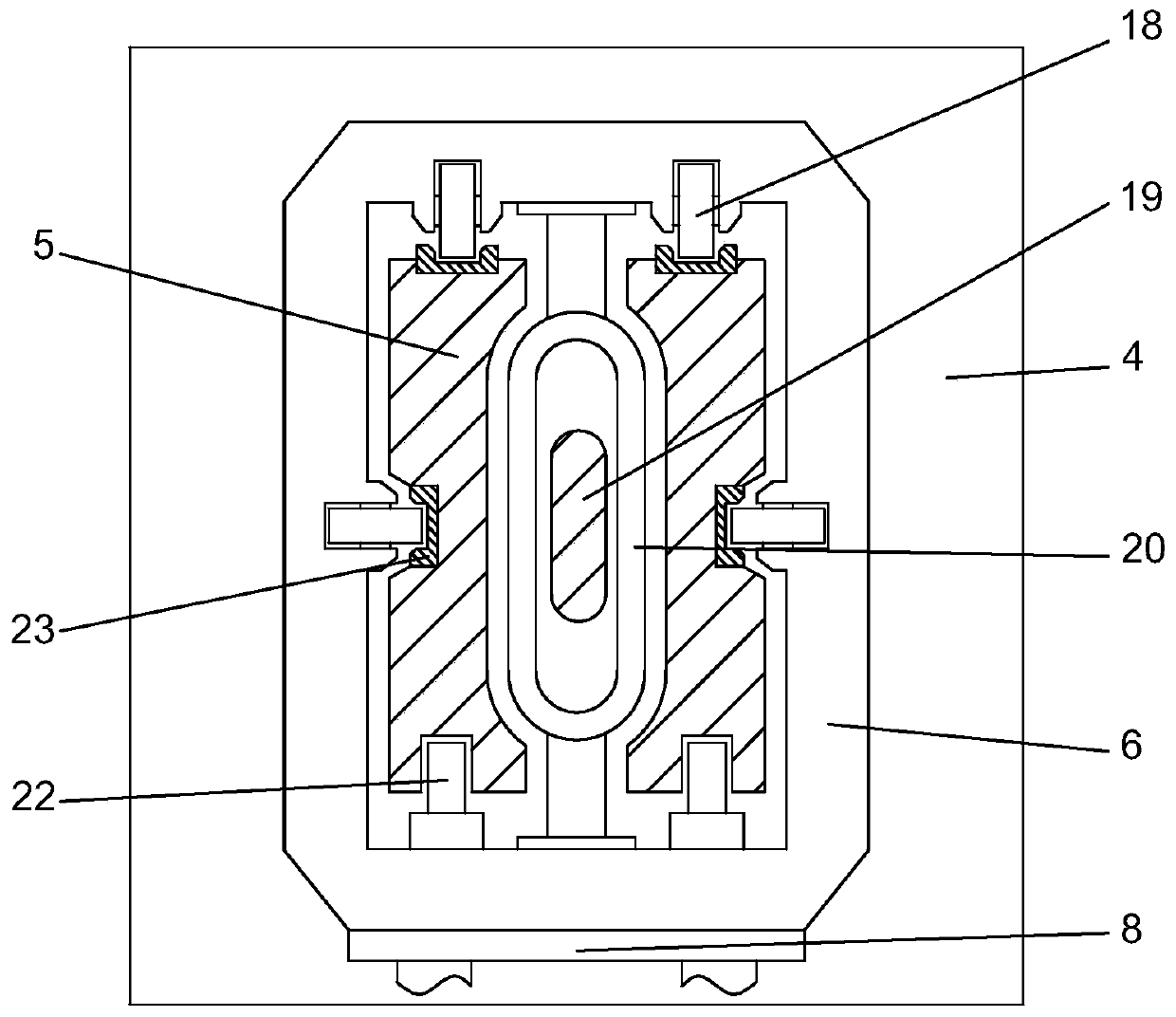

[0027] Concrete embodiment: see appendix Figure 1~4, a wall construction device, comprising a bracket 1, an assembly seat 4 is installed on the top of the bracket 1, a guide rail 5 is installed on the left end of the assembly seat 4, and a sliding joint is slidably connected to the outer side of the guide rail 5, and the bottom of the two sliding joints The first crimping piece 27 and the second crimping piece 28 which are left-right symmetrical are rotatably connected to the end, and the left end of the assembly seat 4 is provided with a limiting plate 19 . The lower end of the support 1 is fixed with a base 29, both the support and the base can be heavy solid iron products, the right end of the assembly seat 4 is fixed with a balance beam 30, and a counterweight 31 is hung on the balance beam, and the counterweight 31 is a plurality of separate structures , easy to increase or decrease, and can be hung on the balance beam through the tray and the lanyard. The bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com