Method and powder for preparing copper water jacket based on low pressure cold spray additive manufacturing technology

A technology of additive manufacturing and cold spraying, applied in the direction of pressure inorganic powder coating, additive processing, etc., can solve the problems of casting defects, poor thermal cooling performance, difficult processing and production, etc., achieve good heat conduction and cooling effect, and ensure heat exchange Effect, the effect of low cost of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

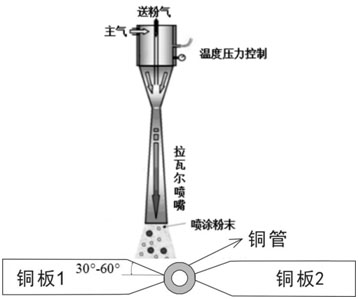

[0013] The present invention is a method and powder for preparing a copper water jacket based on a low-pressure cold spray additive manufacturing technology, and a method for preparing a copper water jacket based on a low-pressure cold spray additive manufacturing technology. The steps are as follows:

[0014] (1) Before spraying, sandblast the copper plates and copper pipes used to prepare the copper water jacket to remove the scale and stains on the cold sprayed surface of the copper plates and copper pipes;

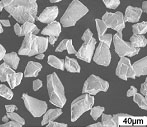

[0015] (2) Use powder materials to prepare cold sprayed copper plates and copper pipes after sandblasting; the spraying parameters are: the working gas for cold spraying is compressed air, the carrier gas temperature is 260-320°C, and the carrier gas pressure is 0.6 -0.8MPa, the spraying distance is 10-20mm, and the spraying speed is 0.4-0.6m / s;

[0016] (3) Put the copper water jacket prepared by cold spraying into the heat treatment furnace. After heat treatment for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com