Four-layer structure screen protection film and manufacturing process thereof

A technology of screen protection film and manufacturing process, applied in the directions of lamination, protective clothing, protective equipment, etc., can solve the problems of difficult to stick, easy to hurt fingers and glue surface, easy to absorb air dust and cilia, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

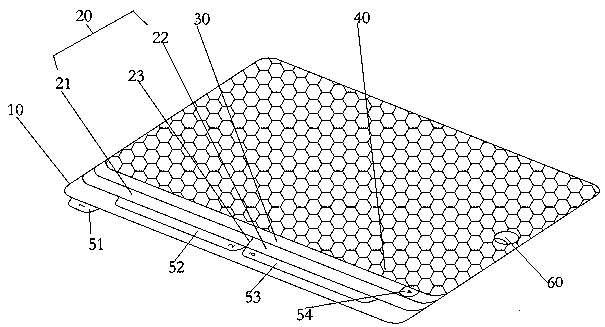

[0047] Such as figure 1As shown, a screen protective film with a four-layer structure includes a bottom release film 10, a single-sided silicone segmented composite release film 20, a single-sided silicone hardened practical film 30, and a top protective film arranged sequentially from bottom to top. 40. In order to improve product quality, the bottom release film 10, the single-sided silica gel segmented composite release film 20, the single-sided silica gel hardened practical film 30, and the top protective film 40 in this embodiment all use PET transparent films, wherein, The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com