Particulate compound fertilizer containing polymeric phosphorus and preparation method thereof

A compound fertilizer and compound fertilizer technology, applied in the field of particulate compound fertilizer containing polymeric phosphorus and its preparation, can solve the problems of excessive application of chemical fertilizers, environmental pollution, cost increase, etc., and achieve the goals of reducing the amount of application, protecting the ecological environment, and reducing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

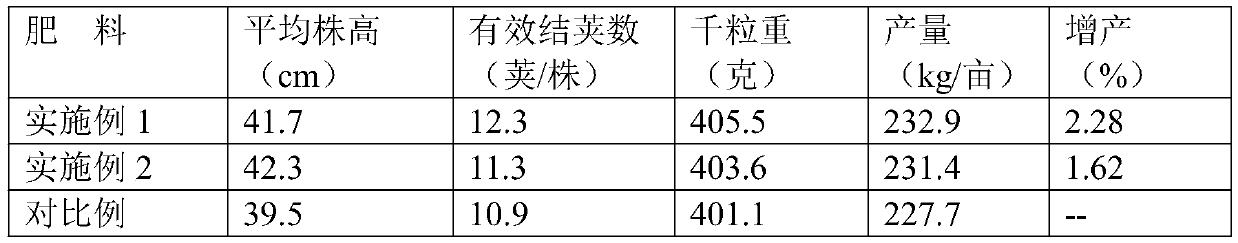

Examples

Embodiment 1

[0031] Take by weight, 28 parts of urea, wet purification phosphoric acid (P 2 o 5 Content is 54%) 65 parts are mixed, and mixing temperature is 60 ℃, and mixing time is 20 minutes, 170 ℃ of high-temperature polymerization reaction 80 minutes, reaction finishes and cools to 40 ℃, obtains powdery polyphosphorus compound fertilizer.

[0032] Weighing 1.5% humic acid of the mass of the powdery polymeric phosphorus compound fertilizer was added to the powdery polymeric phosphorus compound fertilizer to activate it. Then, the obtained powdery polymerized phosphorus compound fertilizer is subjected to a micro-granule extrusion granulation process, and sieved with a vibrating screen of 0.5-1.0mm to produce nitrogen and phosphorus (N+P 2 o 5 ) Particulate compound fertilizer products containing aggregated phosphorus with a total nutrient ≥ 76%.

Embodiment 2

[0034] Take by weight, 30 parts of urea, wet-process concentrated phosphoric acid (P 2 o 5 Content is 46%) 75 parts) and potassium sulfate 7 parts are mixed, mixing temperature is 80 DEG C, mixing time is 30 minutes, 185 DEG C of high-temperature polymerization reaction 90 minutes, reaction is finished and cooled to 50 DEG C, obtains powdery polymeric phosphorus compound fertilizer.

[0035] Weigh 2.0% of the citric acid that accounts for the mass of the powdery polymerized phosphorus compound fertilizer and add it to the powdery polymerized phosphorus compound fertilizer to activate it.

[0036] The obtained powdery polymerized phosphorus compound fertilizer is sieved by a 0.5-1.0mm vibrating sieve through a boiling fluidized granulation process to produce nitrogen, phosphorus and potassium (N+P 2 o 5 +K 2 O) The granular compound fertilizer product containing aggregated phosphorus with total nutrient ≥ 64%.

Embodiment 3

[0038] Take by weight, 31 parts of urea, wet purification phosphoric acid (P 2 o 5 Content is 54%) 30 parts, 9 parts of monoammonium phosphate and 44 parts of potassium nitrate are mixed, the mixing temperature is 100 ° C, the mixing time is 35 min, 200 ° C high temperature polymerization reaction for 120 minutes, the reaction is completed and cooled to 50 ° C to obtain powdery polymerization Phosphorus compound fertilizer.

[0039]Humic acid accounting for 2.0% of the mass of the powdery polymerized phosphorus compound fertilizer was weighed and added to the powdery polymerized phosphorus compound fertilizer to activate it.

[0040] The obtained powdery polymerized phosphorus compound fertilizer is sieved with a vibrating sieve of 0.8 to 1.5mm through a fine particle extrusion granulation process to produce nitrogen, phosphorus and potassium (N+P 2 o 5 +K 2 O) The granular compound fertilizer product containing polyphosphorus with total nutrient ≥ 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com