Method for electrocatalytic preparation of zero-defect disorderly stacked graphene nanofilm and application

A graphene film, defect-free technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of high requirements for graphene preparation, and achieve the goals of improving light conversion efficiency, high sound clarity, and reducing repair temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

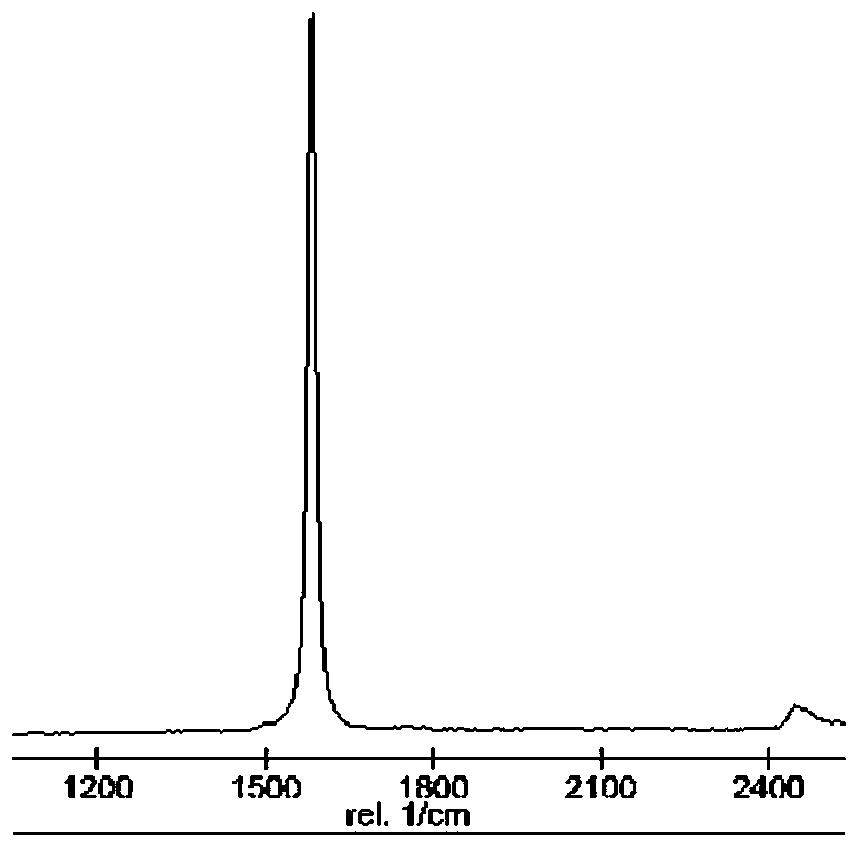

Image

Examples

Embodiment 1

[0038] (1) The graphene oxide is formulated into a graphene oxide aqueous solution with a concentration of 0.5ug / mL, and the mixed cellulose ester (MCE) is used as a substrate to suction and filter into a film.

[0039] (2) Place the graphene oxide film attached to the MCE film in an airtight container and fumigate at a high temperature of 60 degrees HI for 1 hour.

[0040] (3) Coating the melted paraffin uniformly on the surface of the reduced graphene oxide film by evaporation, casting, etc., and slowly cooling at room temperature.

[0041] (4) The graphene film coated with the solid transfer agent is slowly washed with ethanol to dissolve the MCE film.

[0042] (5) The graphene film supported by the solid transfer agent obtained above is slowly volatilized off the solid transfer agent at 120 degrees to obtain an independent self-supporting graphene film, the thickness of the graphene film is about 30 atomic layers, and the transparency is 95 %.

[0043] (6) Gradually heat the graphe...

Embodiment 2

[0048] (1) The graphene oxide is formulated into a graphene oxide aqueous solution with a concentration of 10ug / mL, and the mixed cellulose ester (MCE) is used as a substrate to suction and filter to form a film.

[0049] (2) Place the graphene oxide film attached to the MCE film in an airtight container and fumigate at a high temperature of 100 degrees HI for 10 hours.

[0050] (3) Coating the melted rosin uniformly on the surface of the reduced graphene oxide film by evaporation, casting, etc., and slowly cooling at room temperature.

[0051] (4) Place the graphene film coated with the solid transfer agent in acetone to remove the MCE film.

[0052] (5) The graphene film supported by the solid transfer agent obtained above slowly volatilizes the rosin at 300 degrees to obtain an independent self-supporting graphene film with a thickness of about 60 atomic layers and a transparency of 10%.

[0053] (6) Gradually heat the graphene film to 2000°C at a rate of 45°C / min for 1 hour, and the...

Embodiment 3

[0058] (1) The graphene oxide is formulated into a graphene oxide aqueous solution with a concentration of 8ug / mL, and the mixed cellulose ester (MCE) is used as a substrate to suction and filter to form a film.

[0059] (2) Place the graphene oxide film attached to the MCE film in a closed container and fumigate for 8 hours at 80 degrees HI.

[0060] (3) Coat the melted norbornene uniformly on the surface of the reduced graphene oxide film by evaporation, casting, etc., and cool slowly at room temperature.

[0061] (4) Place the graphene film coated with the solid transfer agent in isopropanol to remove the MCE film.

[0062] (5) The graphene film supported by the solid transfer agent obtained above is slowly volatilized off the solid transfer agent at 100 degrees to obtain an independent self-supporting graphene film with a thickness of about 200 atomic layers.

[0063] (6) Gradually raise the graphene film to 2000°C with a heating rate of 20°C / min for 1 hour, and then energize the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com