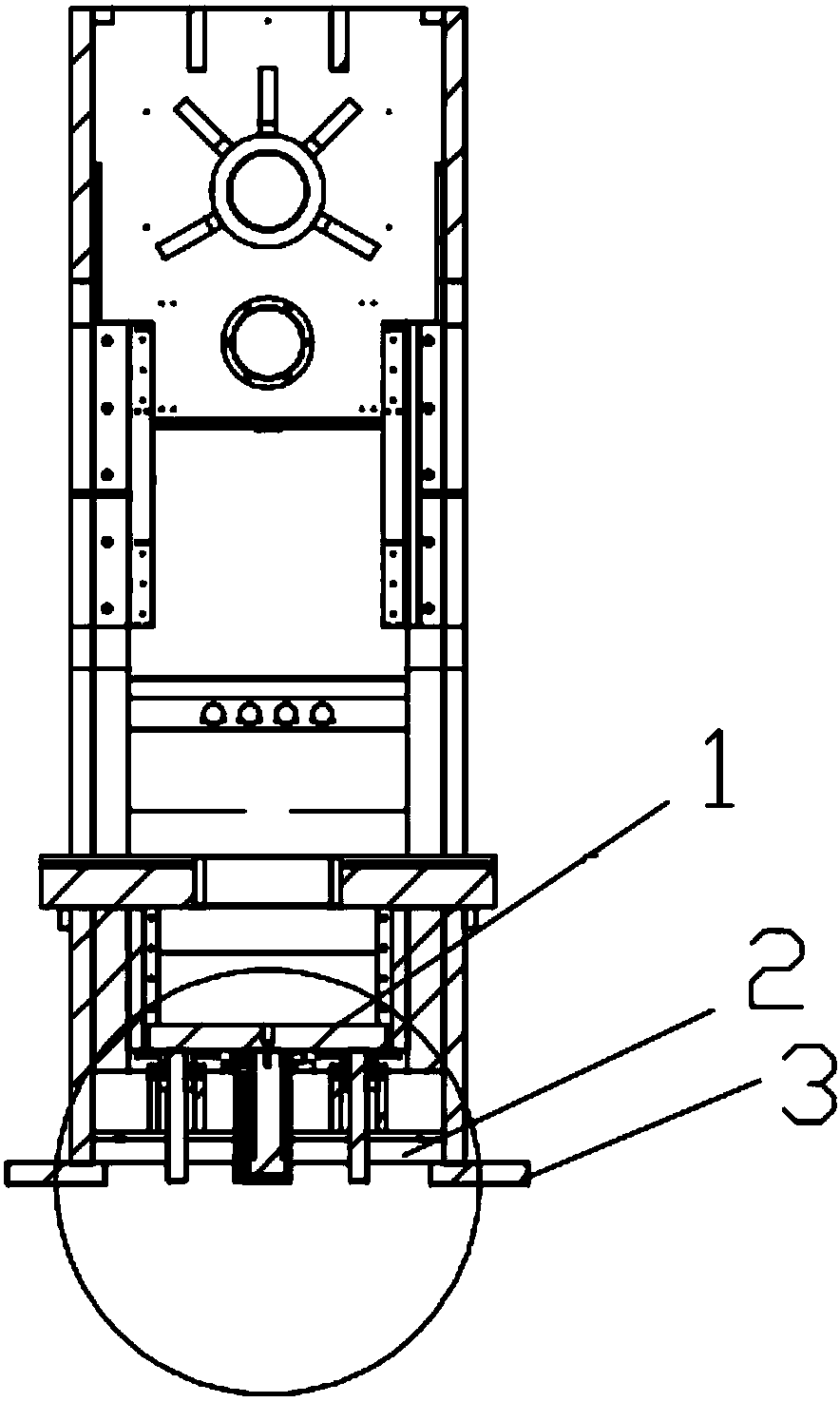

Position adjusting mechanism of punch press ejector plate

A technology of adjusting mechanism and ejector plate, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large vibration, low precision, complex movable mold structure, etc., and achieve high production efficiency, high position adjustment precision, and reduced occupied volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

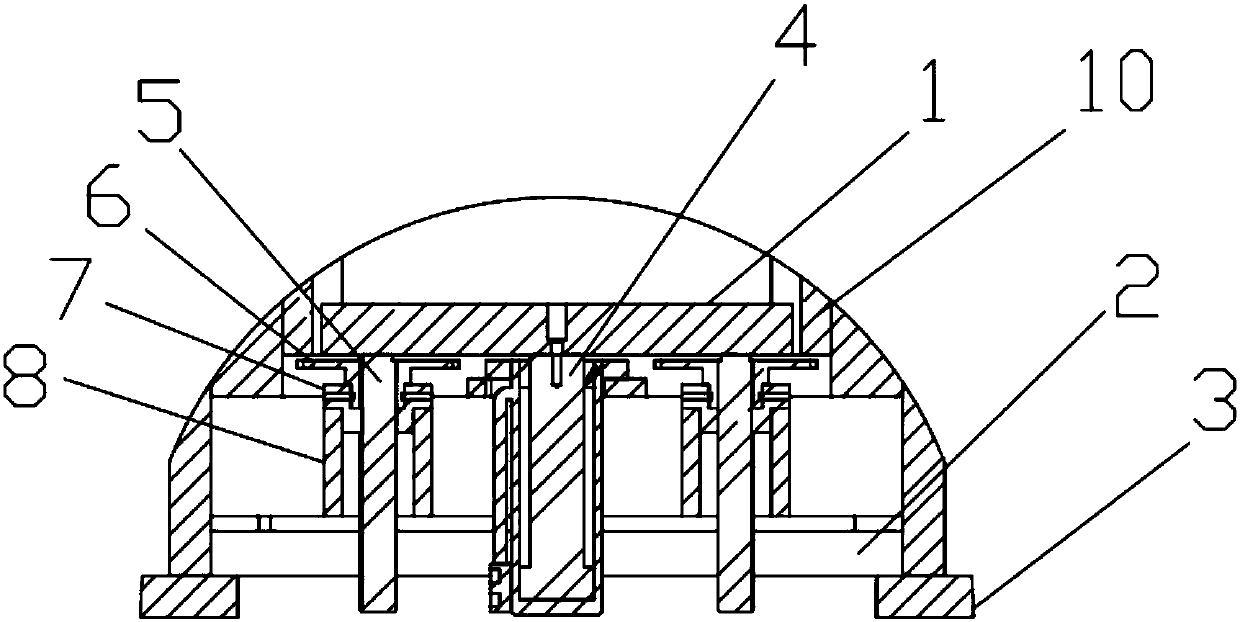

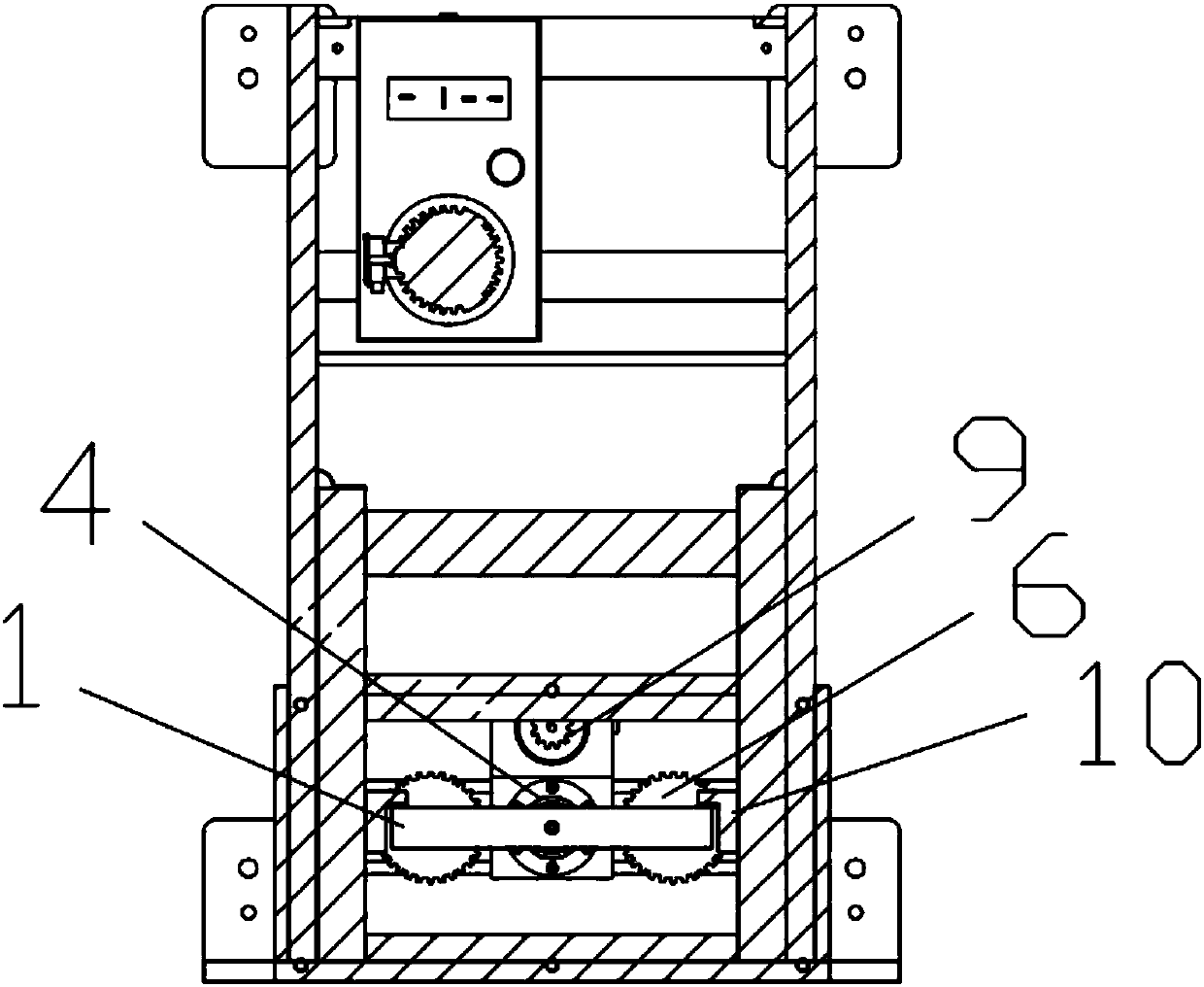

[0018] When in use, first open the oil cylinder 4, under the limit action of the guide plate 10, adjust the position of the ejector plate 1 through the piston rod of the oil cylinder 4, and adjust the distance between the ejector plate 1 and the punching die to adapt to the workpiece. Stamping needs, further, turn on the disc motor, drive the driving sprocket 9 at one end of the disc motor shaft to rotate, the driving sprocket 9 drives the driven sprocket 6 on both sides to rotate through the chain, and the driven sprocket 6 is on the bearing 7 Under the support, the screw rod 5 is rotated to move upwards. Further, the upper end of the screw rod 5 bears against the ejector plate 1. Under the support of the screw rod 5, the movable mold of the punching machine presses downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com