Pre-welding cleaning device for battery cover plate sealing welding

A battery cover and cleaning device technology, applied in cleaning methods and appliances, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of high labor costs and difficulty in ensuring the consistency of cleaning levels, and achieve consistency Sexuality and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

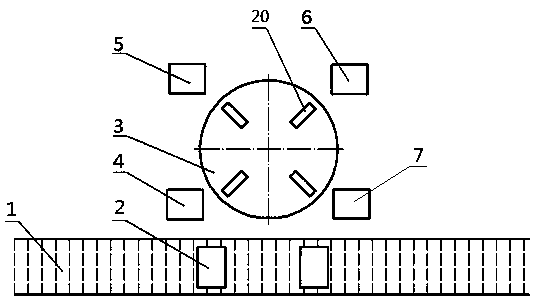

[0024] Specific embodiment one of the battery cover plate sealing welding pre-welding cleaning device of the present invention, as figure 1 As shown, it includes a turntable 3 arranged on one side of the conveyor belt 1. The turntable 3 includes a loading station 4, a cleaning station 5, an air-drying station 6 and a blanking station 7. There are four positioning stations on the turntable 3. The slot 20 is used for rough positioning of the battery cell, so that the cover plate does not slip or displace when the battery cell rotates on the turntable 3 . The turntable 3 is provided with four lifting platforms, and the four positioning grooves 20 are respectively arranged on the four lifting platforms of the turntable 3. The lifting platforms are pneumatic jacking mechanisms in the prior art, and will not be repeated here. The turntable 3 will stop briefly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com