A compound forming machine for anorectal application

A molding machine, anorectal technology, applied in the direction of dressings, viscous dressings, etc., can solve the problems of mutual misalignment, poor molding effect, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

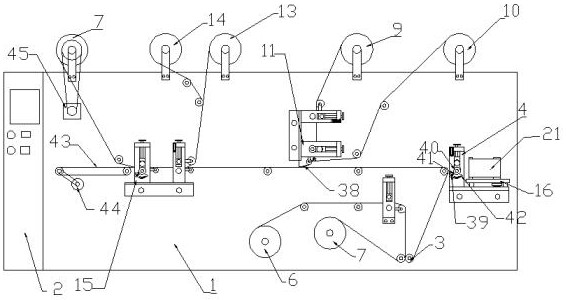

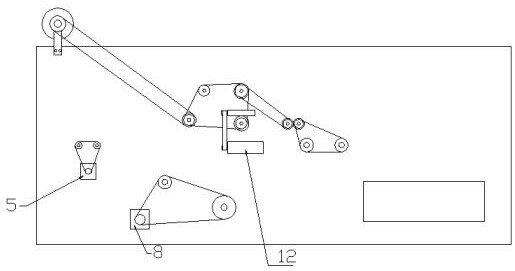

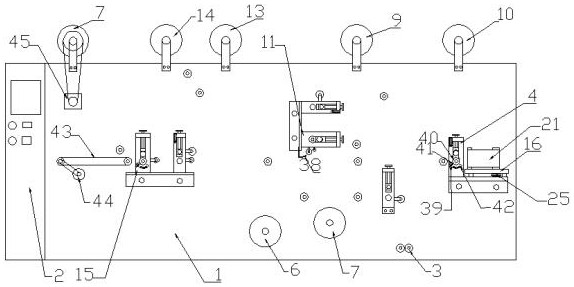

[0038] As the basic embodiment of the present invention, this implementation discloses a compound molding machine for anorectal application, the specific structure is as follows figure 1 As shown, it includes a frame 1, one end of the frame 1 is provided with a controller 2, and the frame 1 is provided with a plurality of guide rollers 3 located in the same plane, so as to ensure that the base layer is quickly and efficiently on the frame 1. Stable transmission, and at the same time, a horizontal processing surface is formed on the frame 1 to ensure the effective connection between various processing equipment, and the frame 1 is divided into cotton processing area, base layer laying area and laminating shearing area in sequence according to functions. Cotton shearing machine 4 and driving motor 5 are arranged in the cotton shearing area, and described cotton shearing machine 4 comprises support 22, and the support 22 is provided with die-cutting roller knife 24 by rolling bear...

Embodiment 2

[0040] This embodiment is another preferred embodiment of the present invention, and its specific structure is as follows: figure 1 As shown, the cotton shearer 4 inlet end is also provided with a cotton pressing machine 16, and the cotton pressing machine 16 is symmetrically provided with a left pressing roller 17 and a right pressing roller 18 that cooperate with each other, and the left pressing roller 17 and the right pressing roller 18 are arranged symmetrically. The right press rollers 18 are connected by a transmission gear 25, and the transmission motor 5 is connected to any one of the left press roller 17 or the right press roller 18 by a transmission gear 25; The left rotary shaft 19 and the right rotary shaft 20 that are compatible with the left press roller 17 and the right press roller 18, a cotton pressing belt 21 is sleeved between the left rotary shaft 19 and the left press roller 17, and the right rotary shaft 20 and the right press roller 18 There is an embos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com