Battery pack

A technology for battery packs and battery cells, applied to battery pack components, secondary batteries, circuits, etc., can solve problems such as heavy loads and dangers, and achieve the effect of suppressing fracture and reducing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

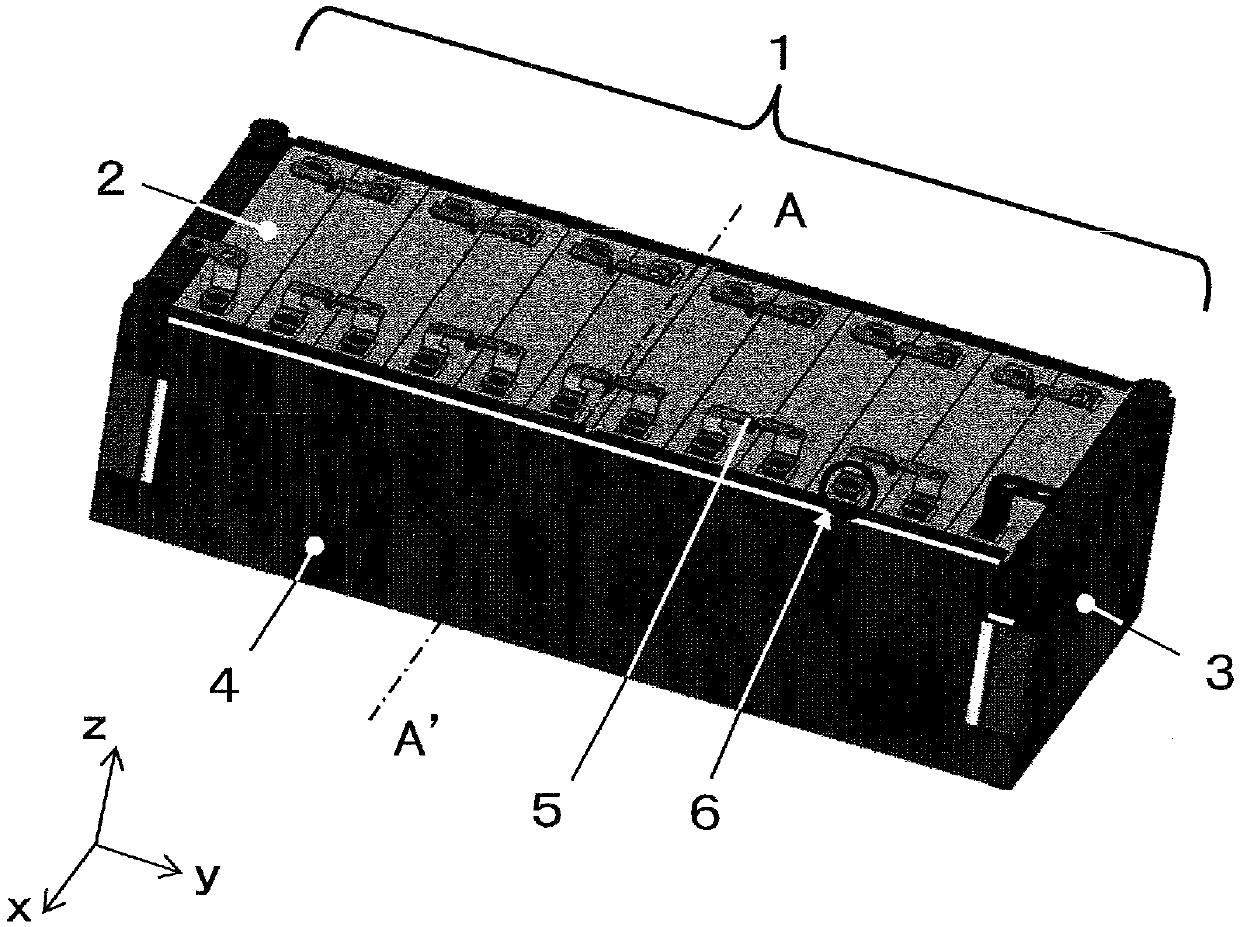

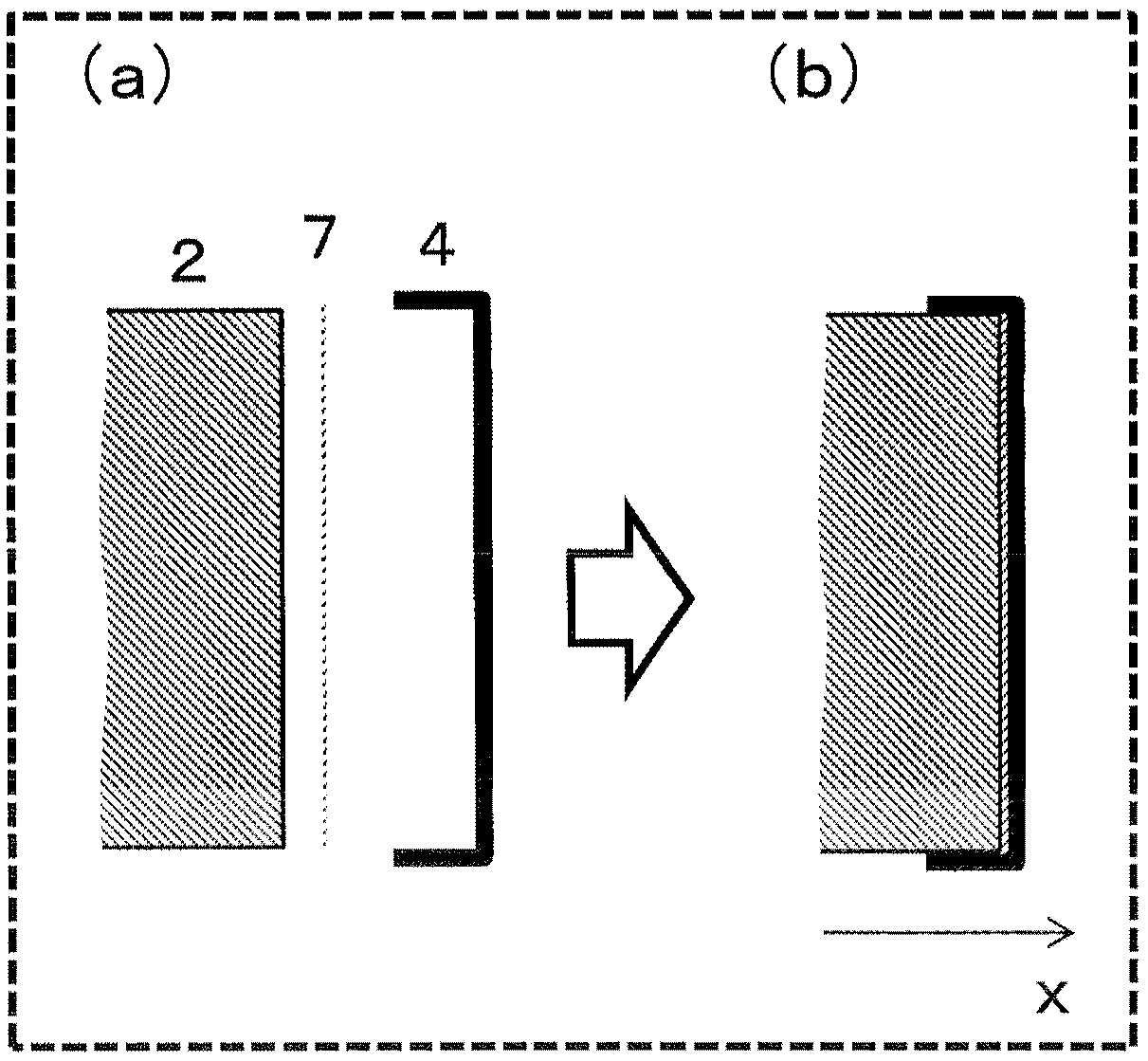

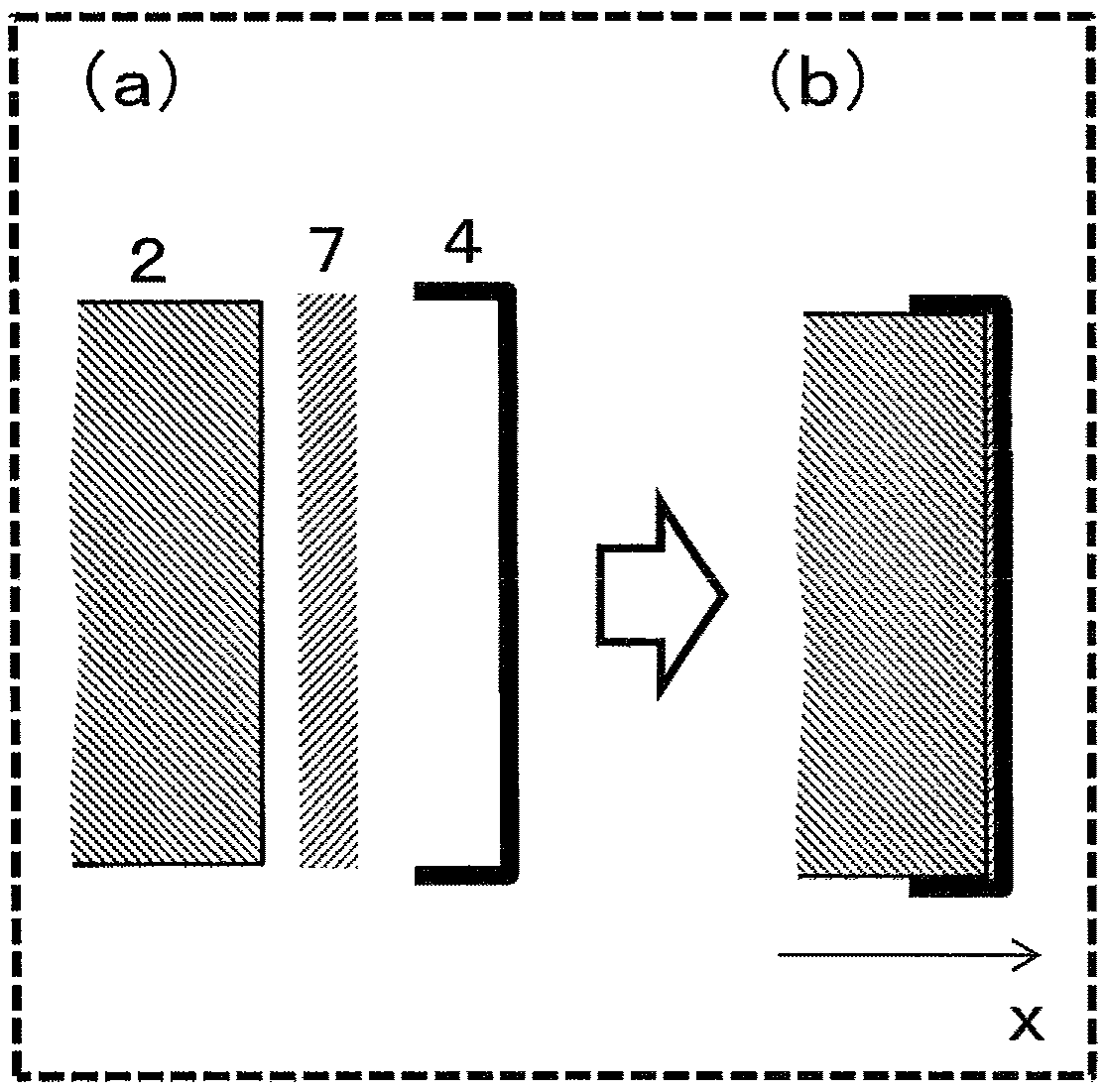

[0040] Figure 1A It is a perspective view showing the whole of the battery pack 1 according to Embodiment 1 of the present invention. Figure 1B (a) means Figure 1A An exploded view of the structure of the battery cell 2 , the thin insulator 7 and the connecting rod 4 between the battery cell 2 and the end plate 3 at one end of the battery pack 1 . Figure 1B (b) is after Figure 1A The broken line A-A' of the battery pack 1 and the section of the battery pack 1 perpendicular to the arrangement direction (y direction) only show the schematic cross-sectional view of the battery unit 2, the connecting rod 4 and the insulator 7 of (a). Figure 1C (a) means Figure 1A An exploded view of the structure of the battery cell 2 , the thick insulator 7 and the connecting rod 4 between the battery cell 2 and the end plate 3 at one end of the battery pack 1 . Figure 1C (b) is after Figure 1A The broken line A-A' of the battery pack 1 and the section of the battery pack 1 perpendi...

Embodiment approach 2

[0073] In Embodiment 1, the structure in which the compressed insulator 7 arranged between the battery cells 2 and the connecting rods 4 is interposed is adopted. In the battery pack according to Embodiment 2, the structure is different in that the assembled battery pack 1, the insulator 7 is bonded to one or both of the connecting rod 4 or the battery unit 2 . Since the insulator 7 is bonded to at least one of the connecting rod 4 or the battery cell 2, the displacement of the battery cell 2 when impacted in the alignment direction is smaller than that of the first embodiment in which only friction acts. Therefore, it is possible to further reduce the load on the welding portion acting between the electrode terminal 6 and the bus bar 5 .

[0074] In addition, for the case where the outer surface of the battery cell 2 is made of a metal material or the connecting rod 4 made of a metal material, by roughening the surface, the coefficient of friction can be increased, and a bett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| dynamic friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com