A rotating sample stage device based on atomic force microscope

A technology of atomic force microscope and sample stage, which is applied in measuring devices, scanning probe microscopy, instruments, etc., can solve the problems of different force conditions, measurement result errors, and the initial sample stage cannot be rotated at an accurate angle, to achieve The effects of reducing deformation differences, adding functions, and expanding application occasions and research scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

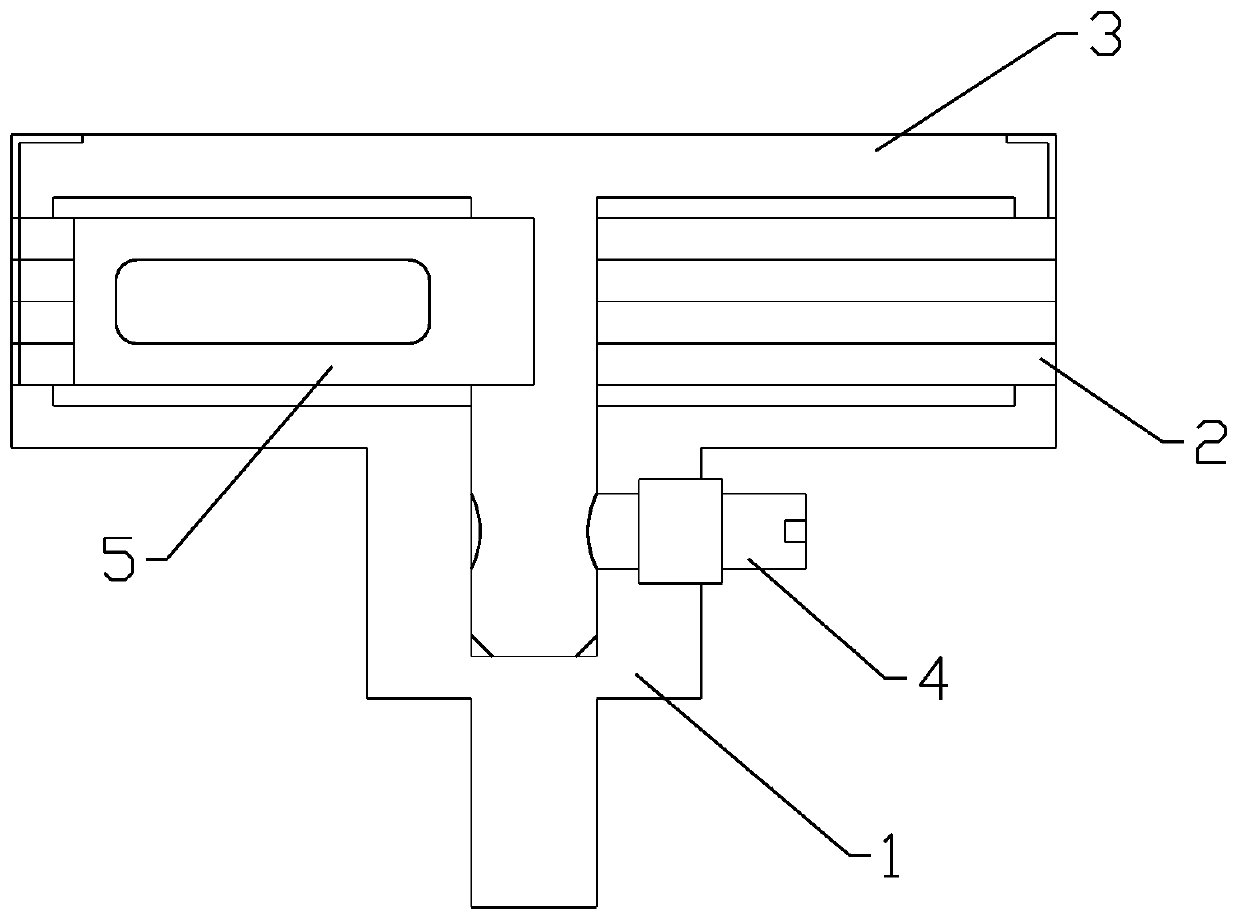

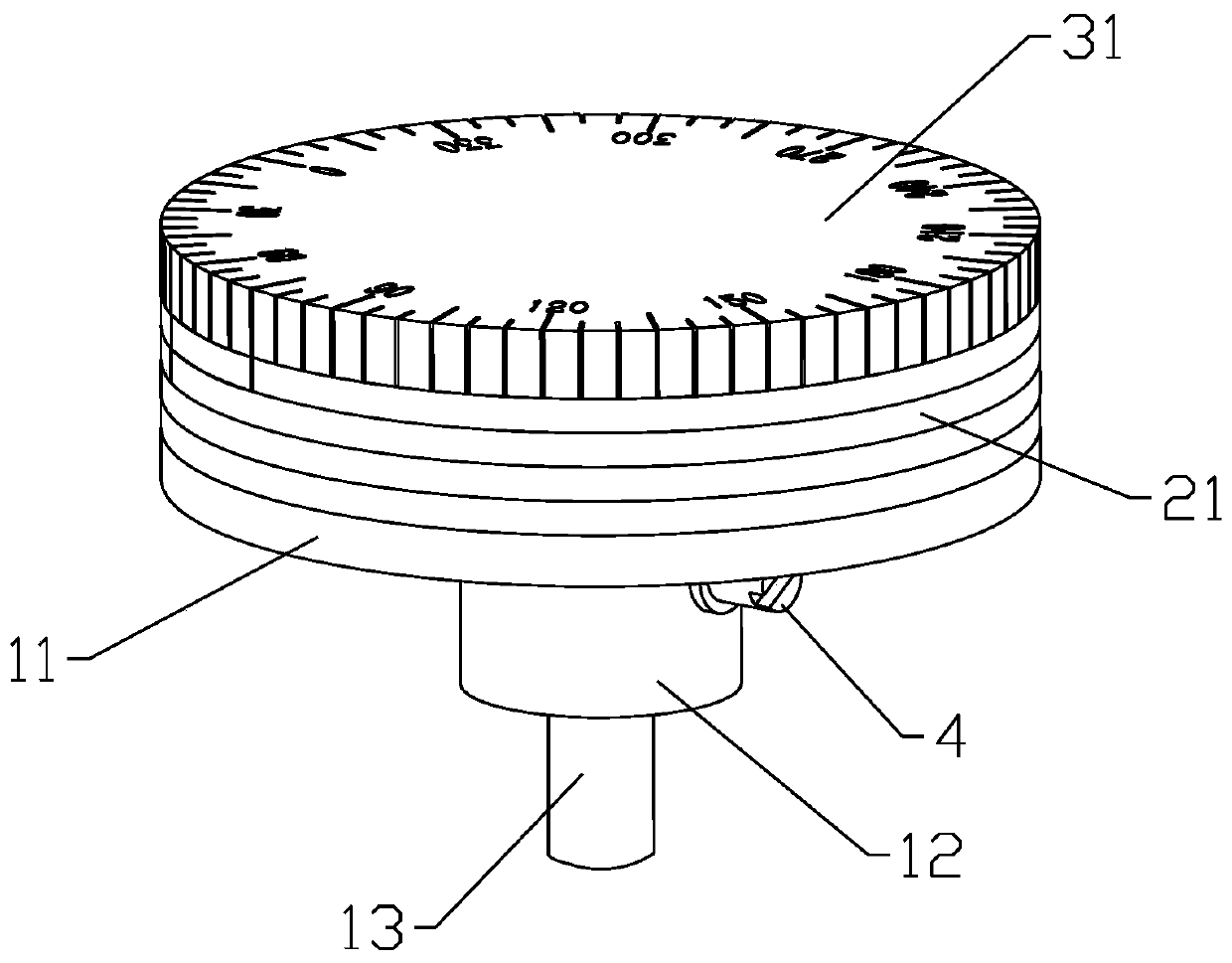

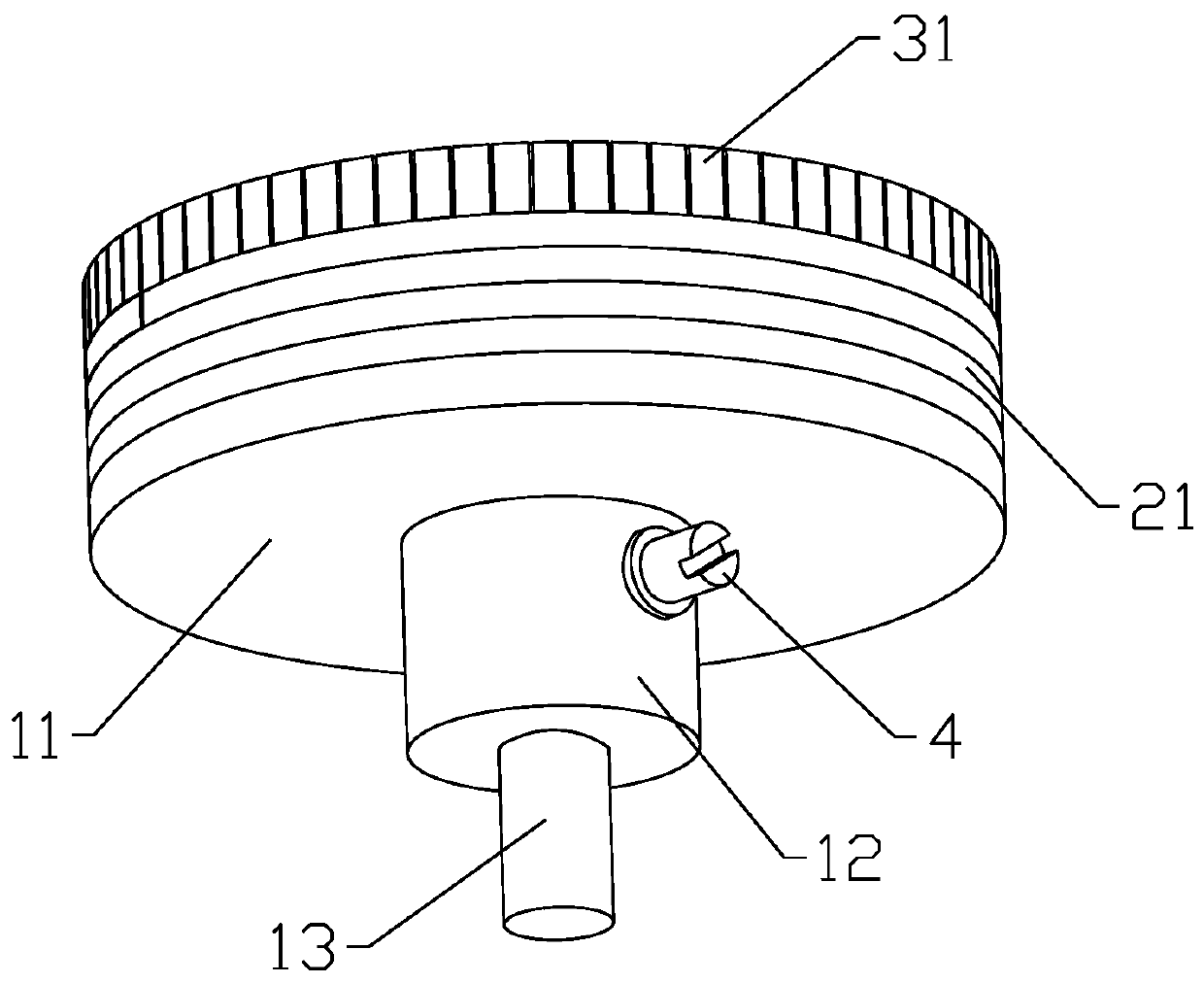

[0033] Please refer to figure 1 , figure 2 and image 3 , this embodiment provides a rotating sample stage device based on an atomic force microscope, which includes: a base 1, a thin ring body 2, a top cover 3, a pin 4 and a spring leaf 5, and the top cover 3, the thin ring body 2 and the base 1 The shapes are matched, and the top cover 3 rotates around the central axis of the three to drive the sample to rotate. It processes a plurality of thin ring bodies 2 with a uniform standard. The inner side of the thin ring body 2 is processed with a plurality of evenly distributed convex teeth 22. The thin ring bodies 2 are stacked with staggered angles in turn to form a whole, so that the protruding teeth 22 in different thin ring bodies 2 can completely divide the circumference, and the bottom surface of the whole thin ring body matches with the edge protrusion of the upper boss 11 of the base 1, and Fixedly connected by welding, the lower boss 12 of the base 1 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com