Press-bending and expanding integrated test device for thin walled tube and method

A test device, thin-walled tube technology, applied in the field of thin-walled tube compression, bending and expansion integrated test device, can solve undisclosed problems, achieve the effect of convenient use and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

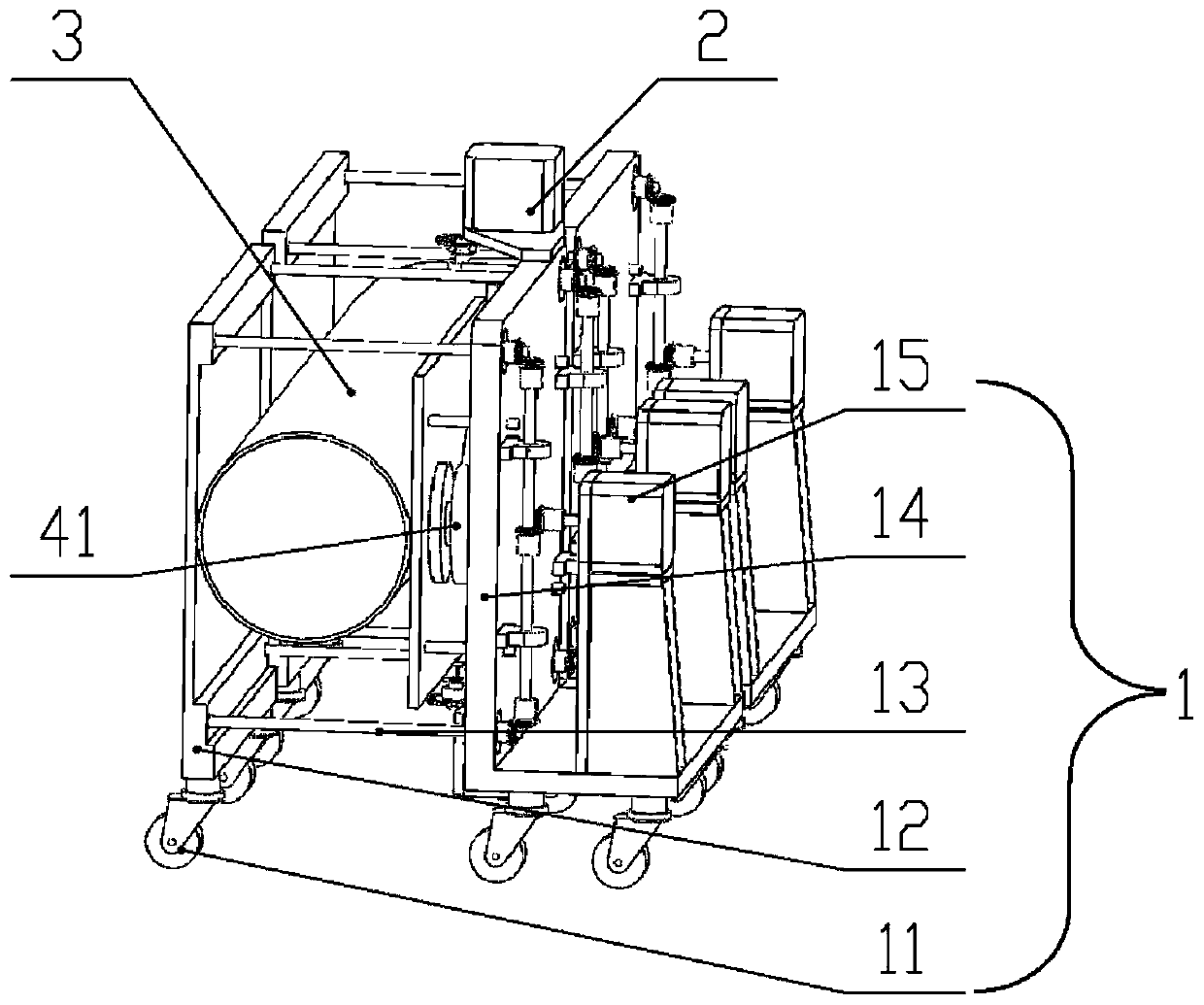

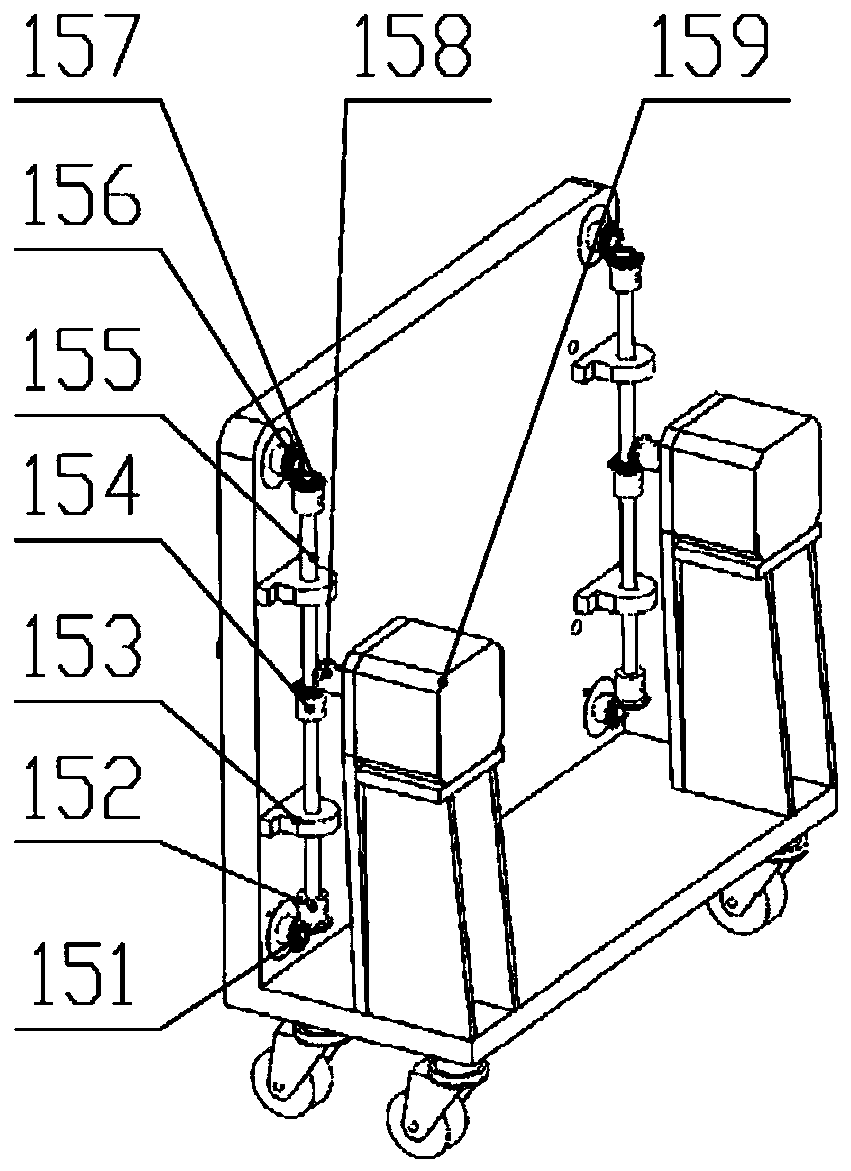

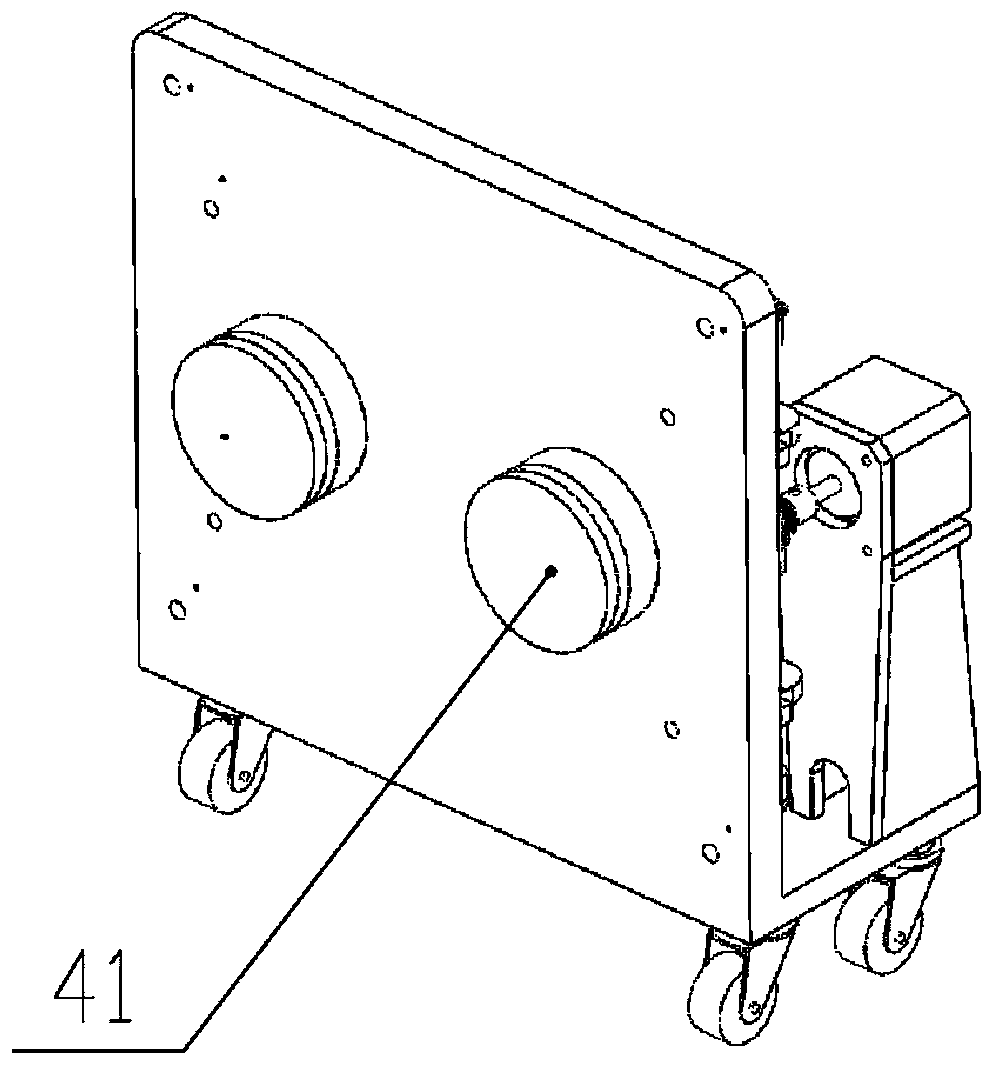

[0040] Such as figure 1 As shown, a thin-walled tube integrated test device for bending and stretching provided by this embodiment includes a flattening mechanism 1, a bending mechanism 2, and a sensor; the flattening mechanism 1 includes a pressing plate 12, a bearing plate 14, a screw mechanism 13, a transmission Mechanism 15, backing plate, bearing plate 14 is L-shaped member, and transmission mechanism 15 is fixedly installed on the right side of bearing plate 14, and pressing plate 12 is installed on the left side of bearing plate 14 movable by screw mechanism 13; Screw mechanism 13 comprises screw Rod, screw nut, the screw is fixedly installed on the pressure plate 12, the screw nut and the bearing plate 14 constitute a rotating pair, the screw passes through the bearing plate 14 through the screw nut; the screw nut and the screw constitute a ball screw transmission pair Or a roller screw transmission pair, the present embodiment is preferably a ball screw transmission p...

Embodiment 2

[0052] On the basis of Embodiment 1, the sensor also includes a displacement sensor. The displacement sensor is configured to detect the relative distance between the pressing plate 12 and the backing plate. The displacement sensor can be arranged between the pressing plate 12 and the backing plate or on the screw rod. In this embodiment Preferably, the displacement sensor is arranged on the screw rod.

Embodiment 3

[0054] On the basis of embodiment 1, the number of crushing mechanisms 1 is three, and the left, middle and right of the three crushing mechanisms 1 are arranged side by side at a time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com