Monitoring device for main bearing of shield tunneling machine

A technology for monitoring devices and main bearings, applied in bearing assembly, shafts and bearings, bearing components, etc., can solve problems such as overmaintenance, undermaintenance, and lack of theoretical basis, so as to reduce the risk of downtime, improve construction efficiency, and ensure construction safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

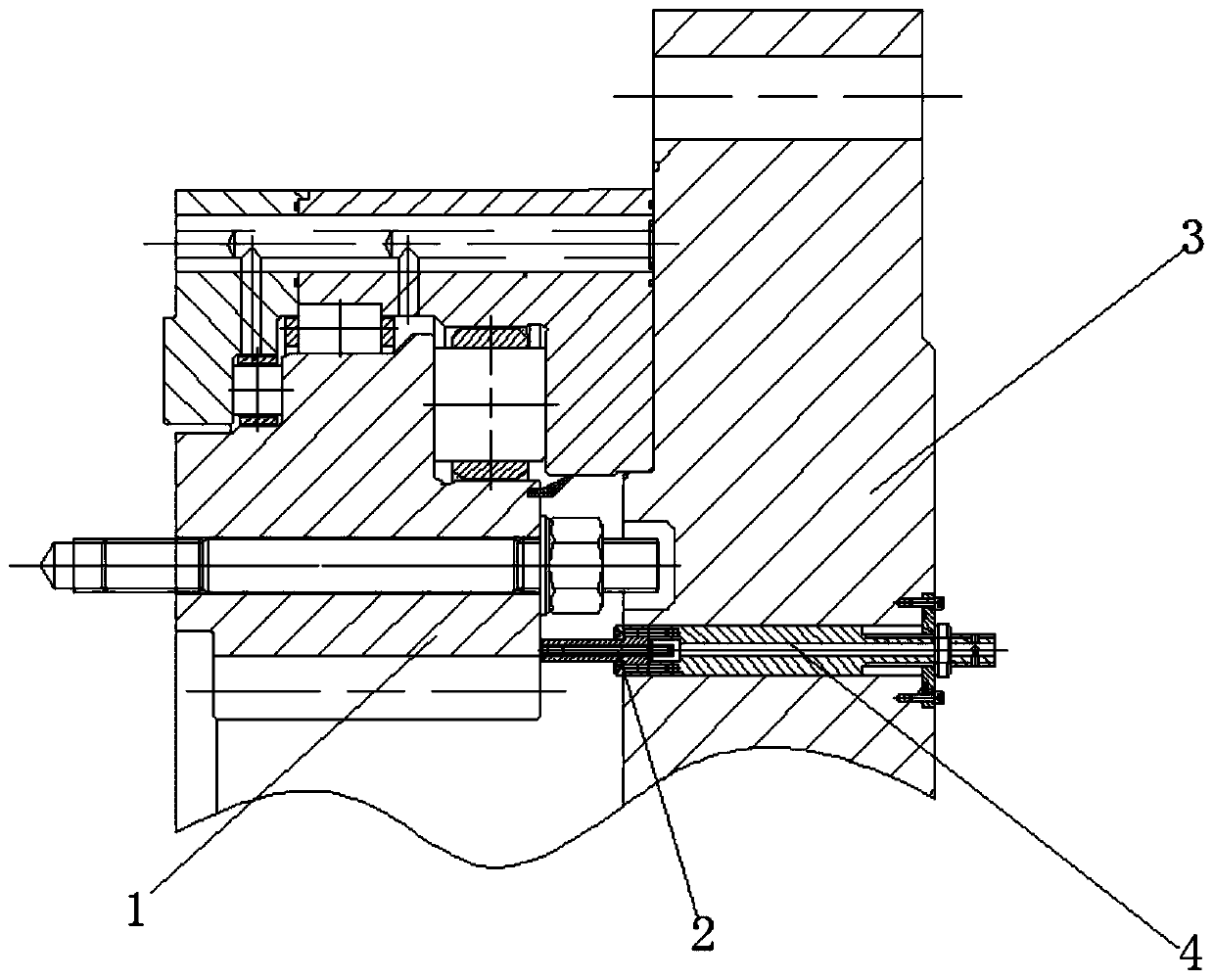

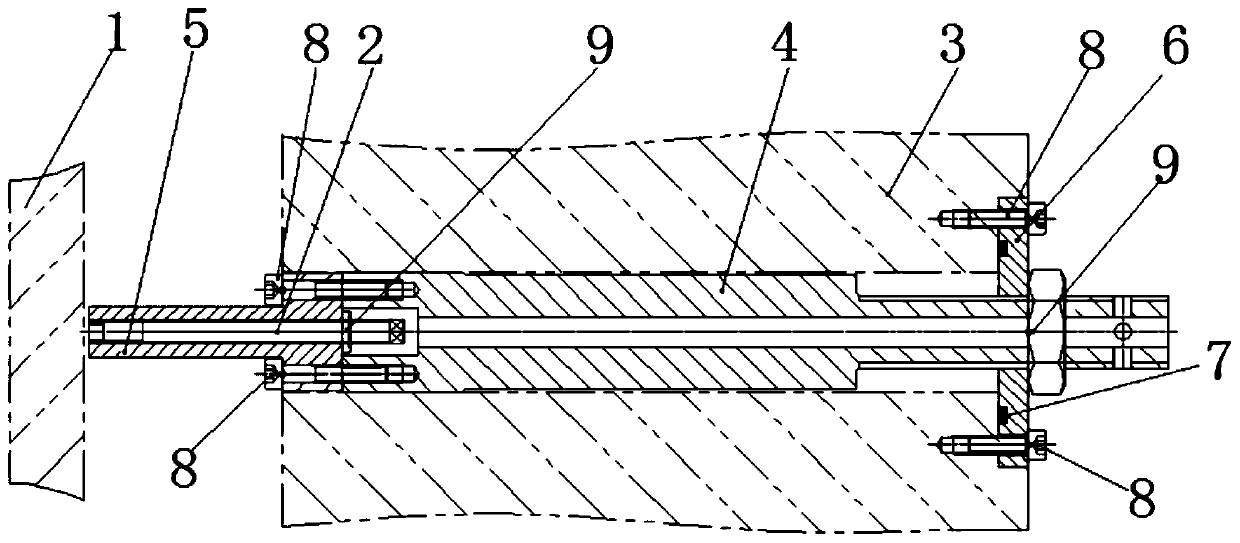

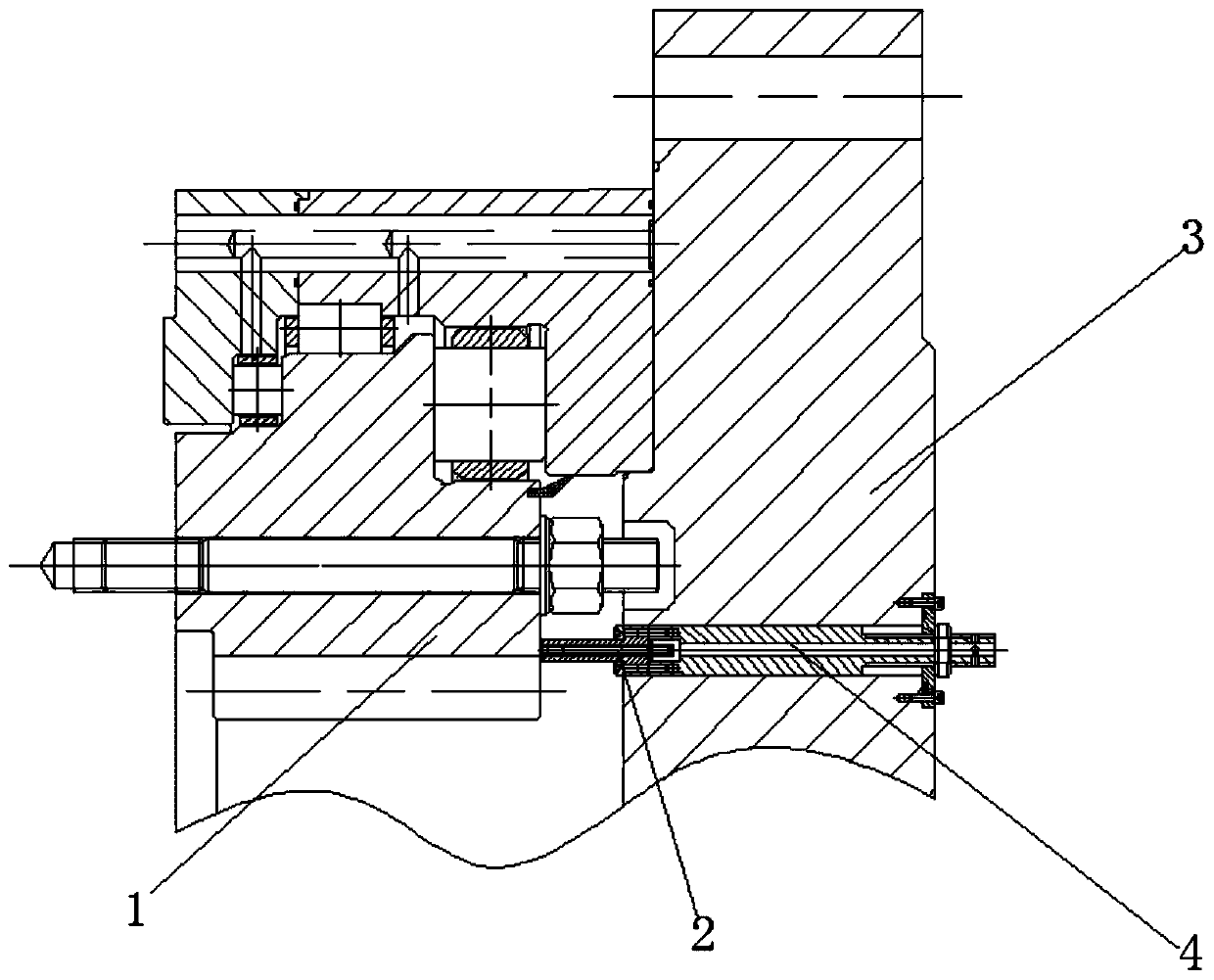

[0019] A main bearing monitoring device of a shield machine according to the present invention comprises a through hole opened on the main drive flange 3 of the shield machine, and a detection head is installed in the through hole close to the inner ring 1 of the main bearing for collecting the main bearing Sensor 2 for axial displacement signal.

[0020] Further, a nylon sleeve 5 is sleeved on the sensor 2, and an installation frame 4 inserted into the through hole of the main drive large flange 3 is sleeved on the end of the sensor 2 away from the main bearing inner ring 1, and the installation bracket 4 and the nylon sleeve 5, and the nylon sleeve 5 is fixed on the mounting frame 4 by bolts 8.

[0021] Still further, the nylon sleeve 5 is fitted on the sensor 2 through thread fit, and a nut 9 is installed on the end of the sensor 2 away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com