Segmented large-diameter screen pipes in underground directional long boreholes of coal mines and its running method

A large-diameter, long-drilling technology, used in directional drilling, mining equipment, earth-moving drilling, etc., can solve the problems of long drilling, screen buckling, and high resistance to bare holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

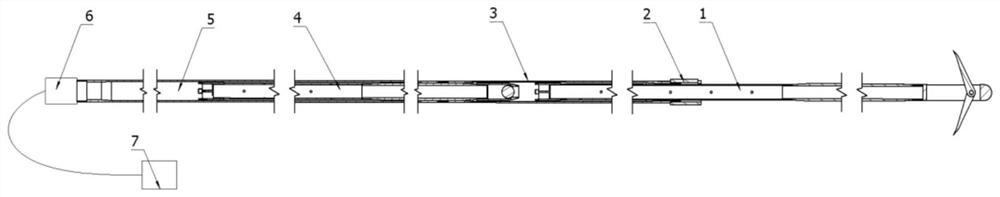

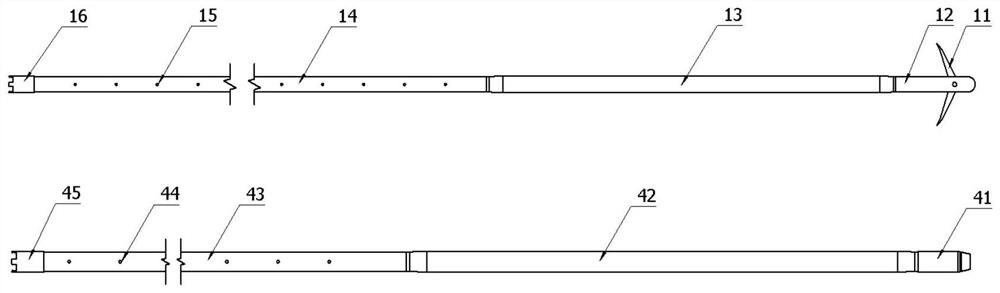

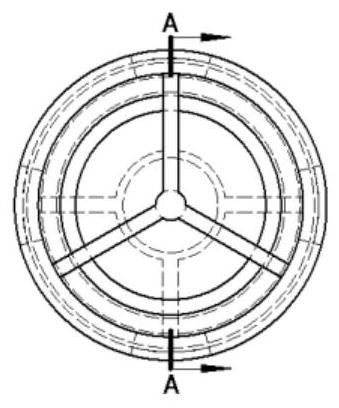

[0034] see figure 1 , figure 2 , image 3 and Figure 3A , shows the sectioned large-diameter screen pipe in the underground directional long drilling hole of the coal mine related to the method of the present invention.

[0035] The segmented large-diameter screen in the directional long borehole of the coal mine is composed of multi-segment screens, which at least include a head-section screen 1 and at least one segmented screen 4, and the head-section screen 1 can pass through the casing milling The drill pipe 3 and the openable and closable drill bit 2 located at the front end of the casing milling drill pipe 3 are located at the front end. The number of the at least one segmented screen pipe 4 can be set according to needs, and each segmented screen pipe 4 can be connected front and back and the same After penetrating through the casing milling drill pipe 3 and the openable and closing drill bit 2, it is connected to the rear end of the head section screen pipe 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com