Fabricated building overhung balcony position external envelope structure

An enclosure structure and prefabricated technology, applied in the direction of building structure, building, housing structure support, etc., can solve the problems of imperfect design consideration, inconvenient construction, poor applicability, etc., to facilitate disassembly and lifting, eliminate safety hazards, Well-designed function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

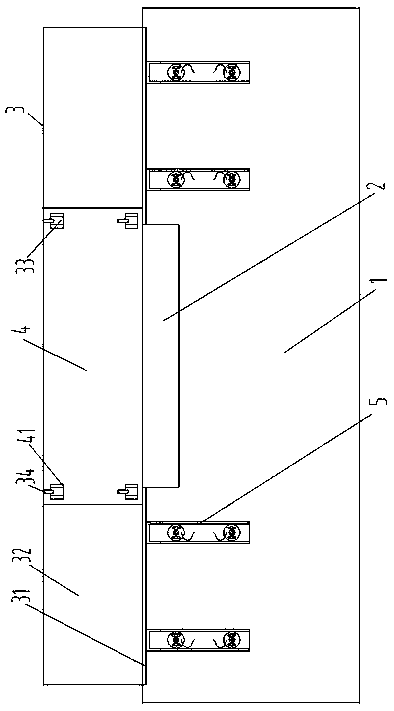

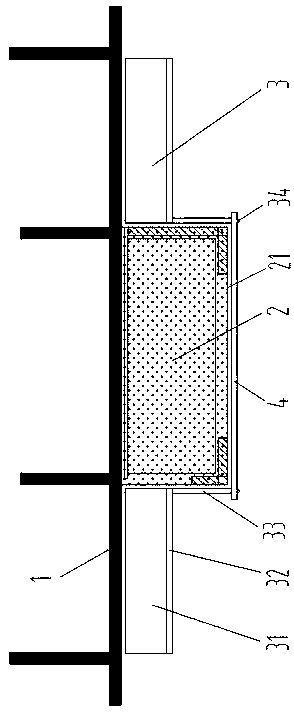

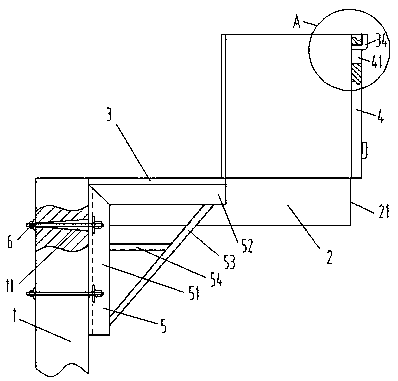

[0030] see Figure 1-3 , the outer protective structure of an overhanging balcony position of a prefabricated building in the first embodiment includes a vertical prefabricated shear wall 1, and the prefabricated shear wall 1 is provided with an overhanging and protruding prefabricated shear wall 1 above. The outer side of the balcony floor surface 2, the outer side of the prefabricated shear wall 1 is connected with two outer protection frames 3; the outer protection frame 3 includes a tripod 5 and a horizontal pedal 31, the pedal 31 The tripod 5 on the lower surface is connected with the prefabricated shear wall 1, the upper surface of the pedal 31 is connected with a vertical front guard plate 32, the front guard plate 32 is the same length as the pedal 31, and the front guard plate 32 is away from the pedal 31. One side of the prefabricated shear wall 1 is flush to protect the construction personnel on the pedal 31; the two outer protective frames 3 are respectively locate...

Embodiment 2

[0045] The difference between the second embodiment and the first embodiment is that, in actual situations, the shape of the prefabricated shear wall 1 and the positional relationship with the overhanging balcony floor surface 2 also have other forms, see Figure 10 , the balcony floor surface 2 is located near the corner of the prefabricated shear wall 1, and one of the two outer protective frames 3 connected to the outer side of the prefabricated shear wall 1 is perpendicular to the balcony floor surface 2, that is, the figure is located at The outer protective frame 3 at the left end of the balcony floor surface 2, on the outer protective frame 3 at the left end, the extension shield 33 extending from one end of the front guard plate 32 close to the balcony floor surface 2 is L-shaped (top view), which also serves to protect the balcony floor. The function of the corresponding end of the face 2, the connecting piece 34 is still arranged on the extension guard plate 33, speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com