Rotating roller with high frequency impact and flexible removal

A technology of high-frequency impact and rotating rollers, which is applied to snow surface cleaning, cleaning methods, construction, etc., can solve the problems of clearing crushing equipment and ice and snow removal equipment that cannot cope with different working conditions, so as to improve strength and stability, increase Stability, less wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

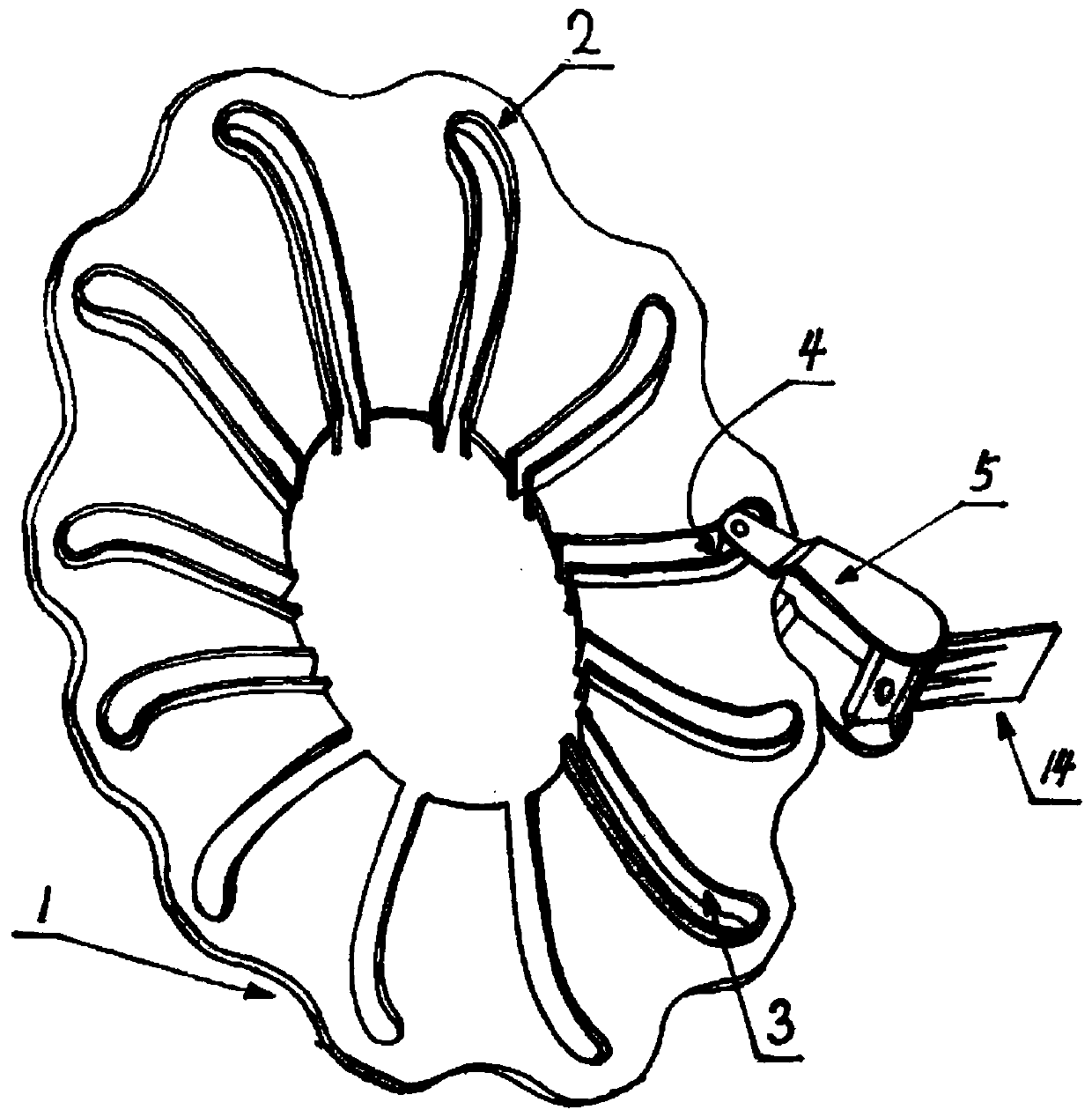

[0055] This embodiment involves a high-frequency impact and flexible cleaning rotating roller, which is specifically realized through the following technical solutions:

[0056] The main structure of the rotating roller includes a main shaft (shaft tube), a wheel disc 1, and an impact device. A plurality of discs 1 are fixed at intervals on the main shaft, and a plurality of impact devices are arranged on the periphery of the discs 1 . The main structure of the impact device includes rollers 4, two side beams 5 of the slats resisting the plane or arc surface of the blade 15, the mounting seat 10, the impact blade 14, and a buffer layer 16 can also be added.

[0057] 1. Roulette Part 1

[0058] Such as figure 1 As shown, the wheel disc 1 of the rotating roller for high-frequency impact and flexible removal is a part that connects and drives the impact device to rotate; The rolling roller needs a track surface, and the narrow inner surface of the long hole of the sheet-shaped...

Embodiment 2

[0080] When this embodiment is in use, the specific operation steps are carried out as follows:

[0081] This technology is a substantial improvement to the previous roulette and impact device. The roulette 1 rotates at a high speed, the roulette 1 is connected and drives the impact device to rotate, and the impact device is thrown away under the action of centrifugal force, and the impact blade 14 is Impact frequency and impact speed, rotary impact clears crushed objects. When running into a hard obstacle and unable to pass, the roller 4 on the top of the impact device slides and rolls towards the center of the wheel 1 in the long hole wide table 2 of the wheel 1, so that the impact device has room to retreat. It is used to remove and crush lighter, thinner and slender objects. It can crush objects by impact. It can selectively remove and crush soft objects from harder objects, avoiding or not damaging harder objects. Because it is an impact movement, the relative instantane...

Embodiment 3

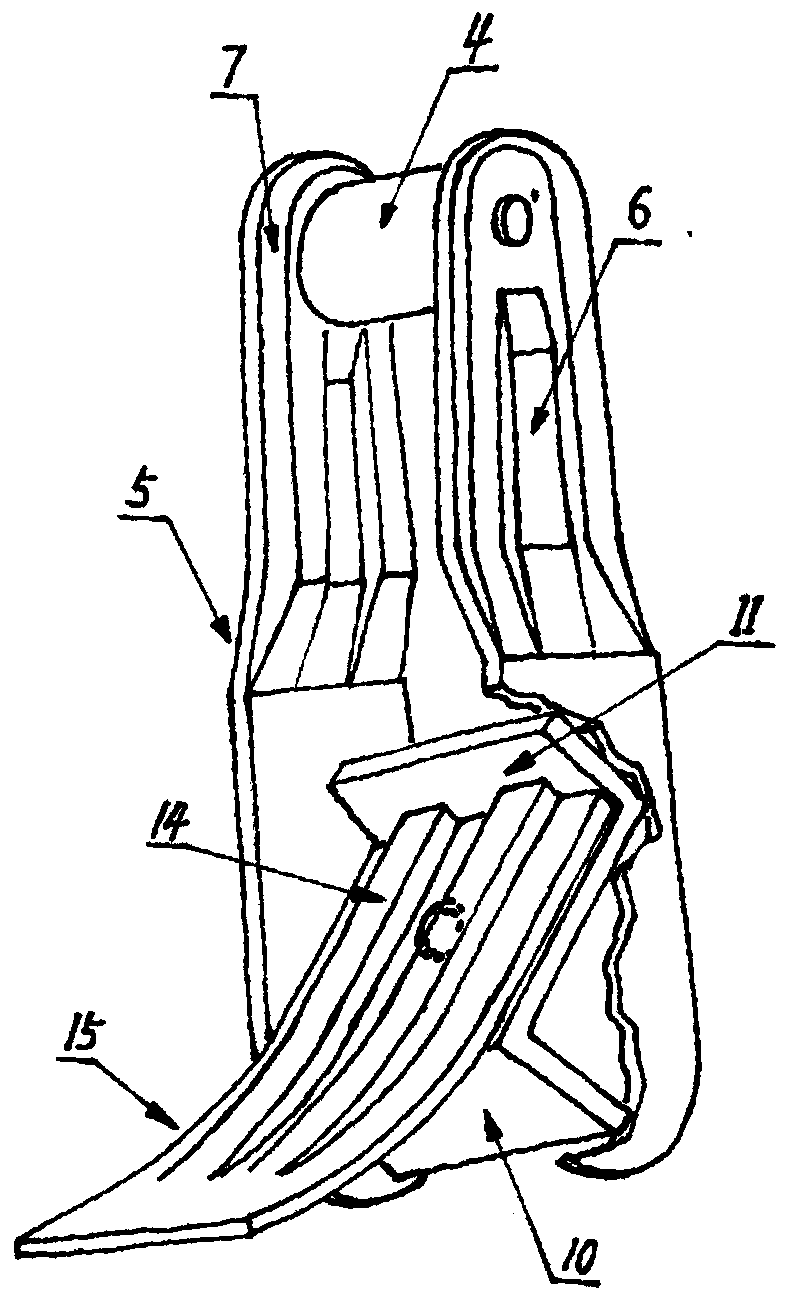

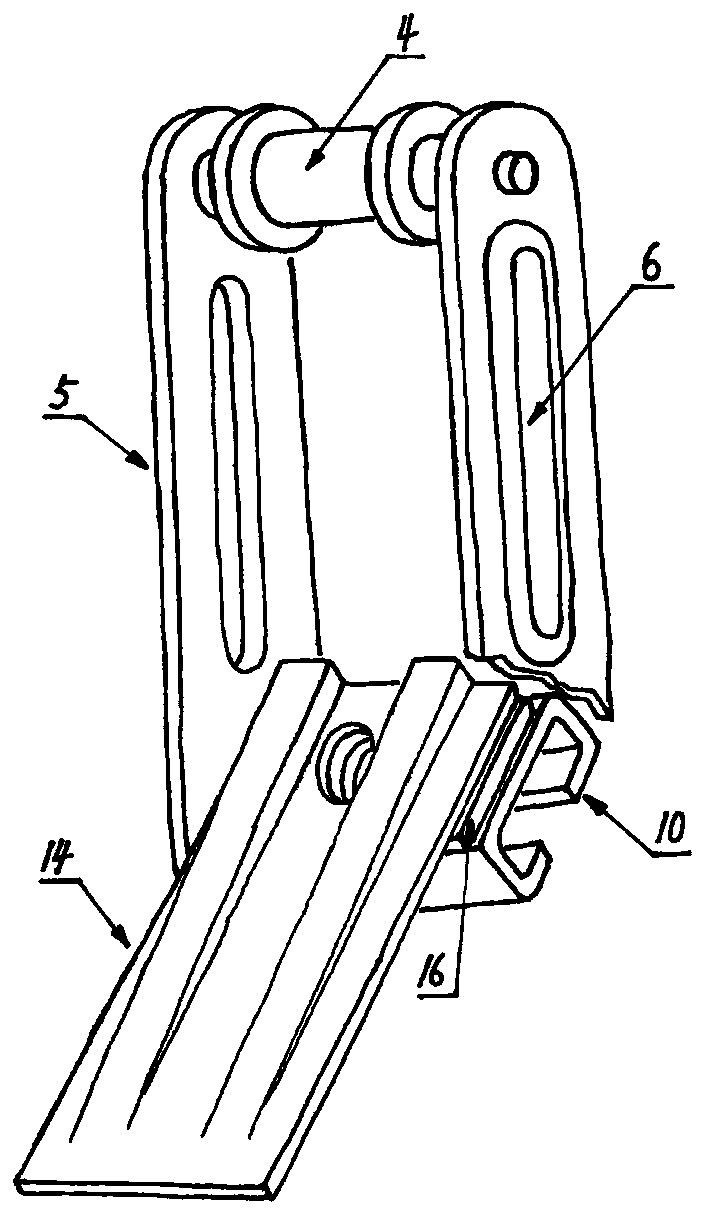

[0083] Such as figure 2 Shown, a kind of high-frequency impact and the rotating roller of flexible removal, roller 4 is installed on the inner surface of the upper end of beam plate 5 on both sides. The beam plates 5 on both sides are bent beam plates, which are in a symmetrical assembly relationship with a narrow top and a wide bottom as a whole. There are concave-convex grooves 6 and slopes 7 on the top of the beam plates 5 on both sides. The concave-convex grooves 6 have a strengthening effect on the beam plates 5 on both sides. When the strength of the beam plates 5 on both sides is sufficient, the concave-convex grooves 6 may not be used; Impact device imports roulette, also can not have inclined-plane 7. The lower part of the beam plate 5 on both sides is a flat plate. The mounting base 10 is a curved plate that is bent into a "Z" shape in section, and the "Z" section of the mounting base 10 two ends is welded or hinged to the bottom inner surface of the beam plates 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com