High-load bearing performance pottery clay pavement brick

A high-load-bearing, clay technology, applied in the field of building materials, can solve problems such as weak bearing capacity and easy breakage, and achieve the effects of reducing manufacturing costs, avoiding breakage, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses a high-load-bearing pavement clay brick, comprising the following raw materials: Chongqing clay, Renshou clay, Guihua Town clay, sintered clay and industrial waste, the weight ratio of the Chongqing clay, Renshou clay and Guihua Town clay is: 30%; the mass ratio of Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 1:1:2; the mass ratio of sintered pottery clay to industrial waste residue is 1:1.2. In this embodiment, the industrial waste slag is specifically selected from iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red bricks, and the ratio of iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red brick is 1:0.5:1.

[0051] The preparation of above-mentioned high load-bearing pavement clay brick comprises the following steps:

[0052] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay, ...

Embodiment 2

[0061] This embodiment discloses a high-load-bearing pavement clay brick, comprising the following raw materials: Chongqing clay, Renshou clay, Guihua Town clay, sintered clay and industrial waste, the weight ratio of the Chongqing clay, Renshou clay and Guihua Town clay is: 40%; the mass ratio of Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 1:0.8:2.1; the mass ratio of sintered pottery clay to industrial waste residue is 1:1.5. In this embodiment, the industrial waste slag is specifically selected from iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red bricks, and the ratio of iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red brick is 1:0.5:1.

[0062] The preparation of above-mentioned high load-bearing pavement clay brick comprises the following steps:

[0063] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery cl...

Embodiment 3

[0072] This embodiment discloses a high-load-bearing pavement clay brick, comprising the following raw materials: Chongqing clay, Renshou clay, Guihua Town clay, sintered clay and industrial waste, the weight ratio of the Chongqing clay, Renshou clay and Guihua Town clay is: 45%; the mass ratio of Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 0.8:1:2.1; the mass ratio of sintered pottery clay to industrial waste residue is 1:0.7. In this embodiment, the industrial waste slag is specifically selected from iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red bricks, and the ratio of iron and steel plant waste slag, lithium salt plant industrial waste slag and waste red brick is 1:0.5:1.

[0073] The preparation of above-mentioned high load-bearing pavement clay brick comprises the following steps:

[0074] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery cl...

PUM

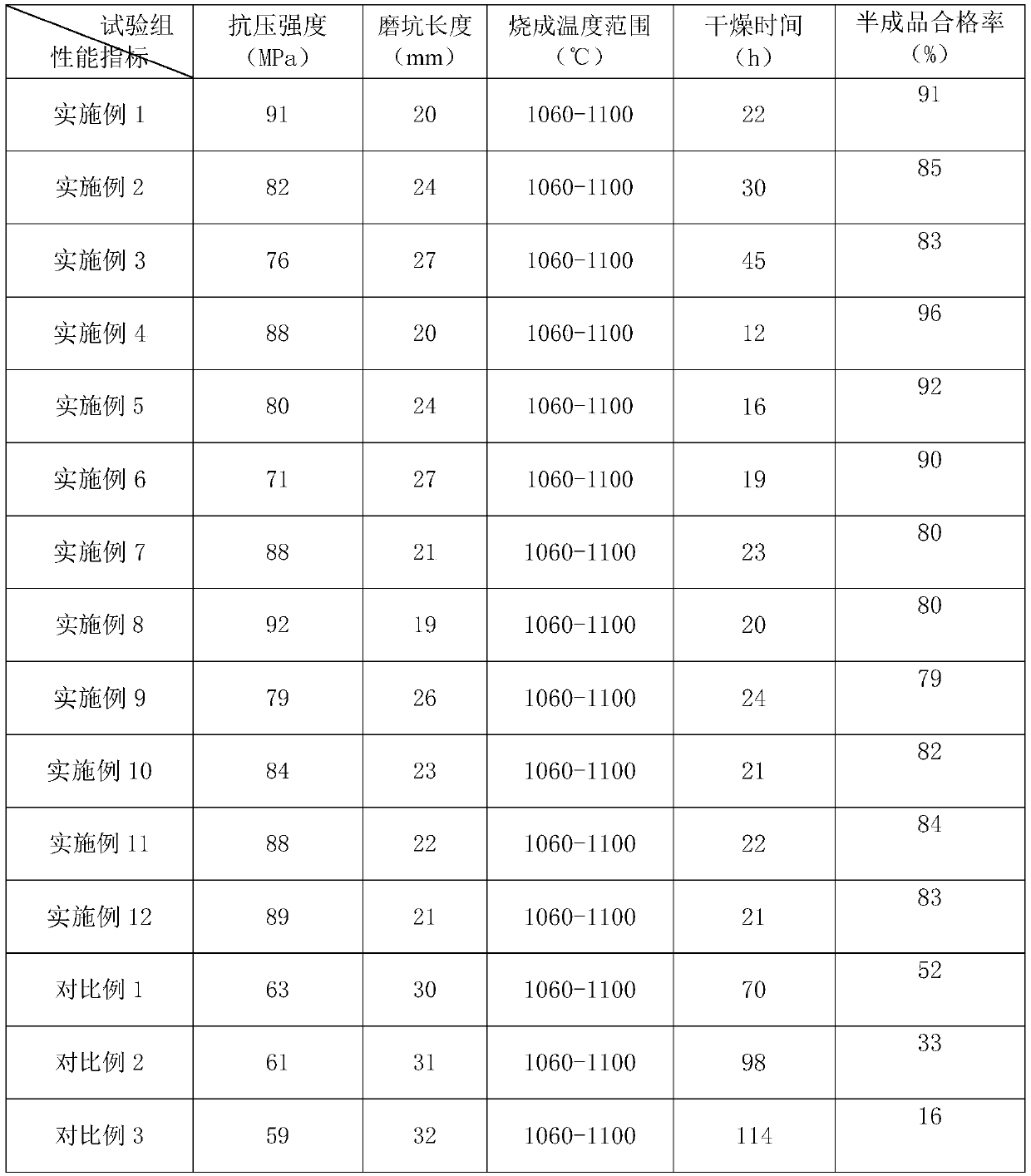

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com