Method for preparing glucoraphanin from glucoerucin

A technology of arugulaside and sulforaphane, which is applied in the field of biochemical pharmacy, can solve the problems of excessive use of reagents, complicated operation, cost and energy consumption, etc., and achieves the effects of good large-scale industrial application, simple operation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

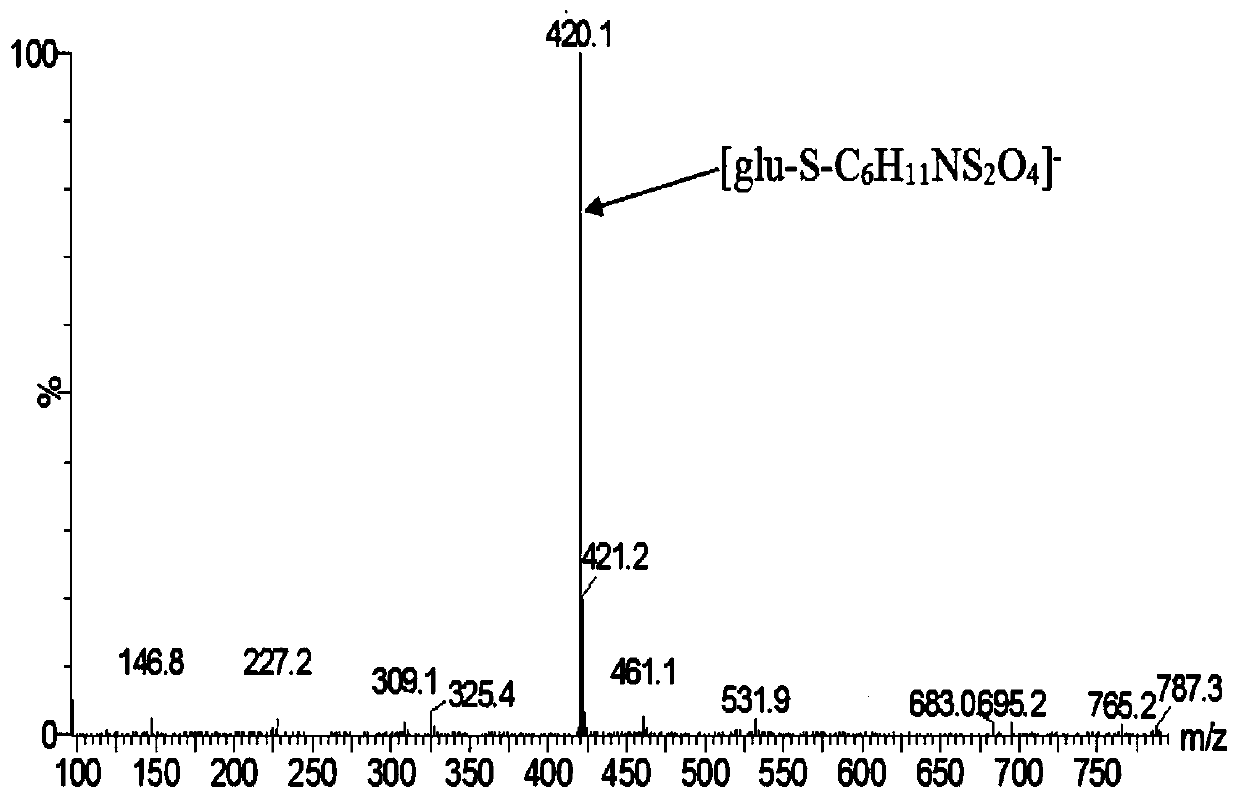

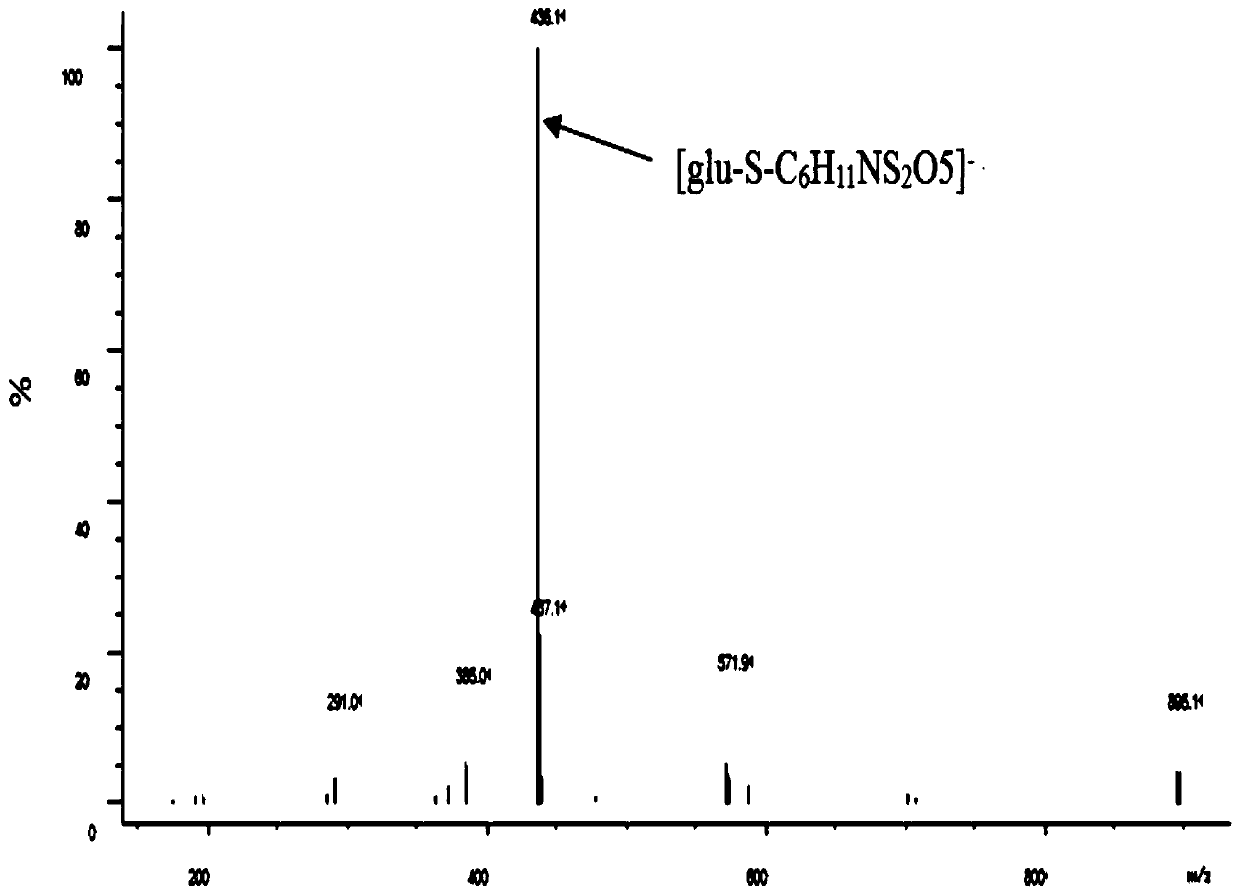

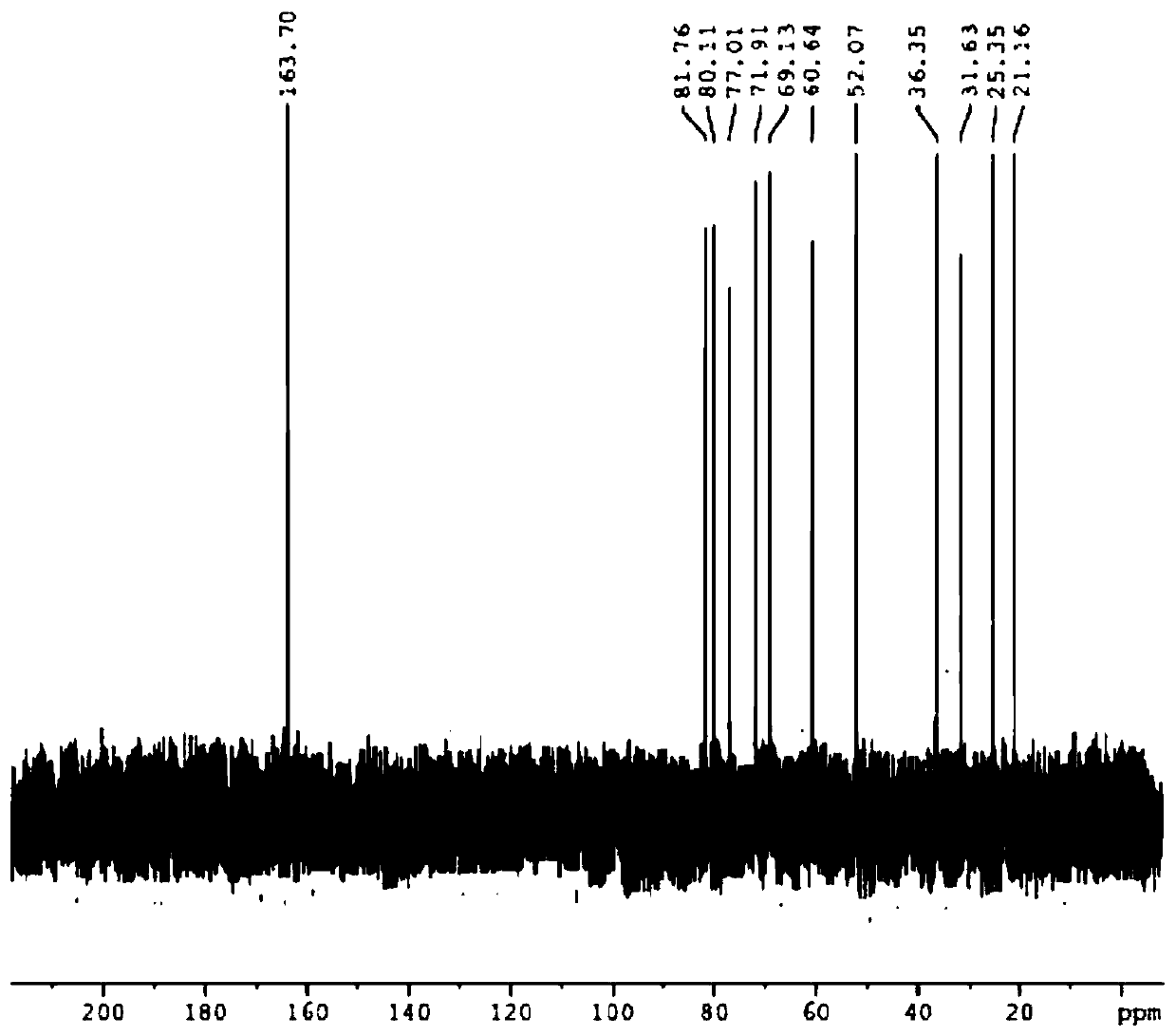

[0030] Preparation of Glucose Sulforaphane (GRA): Glucose sulforaphane is obtained by oxidizing solid aruginoside GER.

[0031] In another specific embodiment of the present invention, in the preparation process of the arugin (GER), the high-temperature stir-frying treatment conditions are specifically: stir-frying at 110-130° C. (preferably 120° C.) for 15-30 min (preferably 20 min) If the temperature is too low, it is not conducive to the subsequent degreasing, and if the temperature is too high, the active ingredients such as arugin will be inactivated.

[0032] In another specific embodiment of the present invention, the specific method of degreasing is: adding petroleum ether to the pulverized arugula seeds, stirring, soaking and degreasing, and the material-to-liquid ratio of the pulverized arugula seeds to the petroleum ether is 1 g: 1.5-3 mL (preferably 1g: 2mL);

[0033] In yet another specific embodiment of the present invention, the specific method of the thermal e...

Embodiment 1

[0047] (1) Preparation of arugin (GER)

[0048] Stir fry 100 g of arugula seeds at 120° C. for 20 minutes, and then pulverize after cooling. 200 mL of petroleum ether was added for stirring, soaking and degreasing, and the supernatant was removed by centrifugation. The solid powder was naturally air-dried at room temperature. Take the air-dried solid powder, add 1 L of deionized water, extract with boiling water at 120°C for 20 minutes, suction filter and collect the filtrate. The filter cake was extracted twice, and the two filtrates were combined to obtain a crude extract of GER.

[0049] Two resin columns in series are used for separation and purification from crude extract, the first resin column is filled with polyglycidyl methacrylate (PGMA) resin for decolorization of crude extract, and the second resin column is filled with strong base Anion exchange resin D261 resin is used for adsorption separation. After the adsorption reached saturation, 10% ammonia water was se...

Embodiment 2

[0057] (1) Preparation of arugin (GER)

[0058] Stir fry 100 g of arugula seeds at 120° C. for 20 minutes, and then pulverize after cooling. Add 250 ml of petroleum ether for stirring, soaking and degreasing, centrifuging to remove the supernatant, and the solid powder is naturally air-dried at room temperature. The air-dried solid powder was added to 1.1 L of deionized water, extracted with boiling water at 120° C. for 20 minutes, and the filtrate was collected by suction filtration. The filter cake was extracted twice, and the two filtrates were combined to obtain a crude extract of GER.

[0059] Two resin columns in series are used for separation and purification from crude extract, the first resin column is filled with polyglycidyl methacrylate (PGMA) resin for decolorization of crude extract, and the second resin column is filled with strong base Anion exchange resin D261 resin is used for adsorption separation. After the adsorption reached saturation, 10% ammonia wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com