A kind of purification method of 2-methyl-4-isothiazolin-3-one

A technology of isothiazoline and purification method, applied in the direction of organic chemistry, etc., can solve problems such as low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

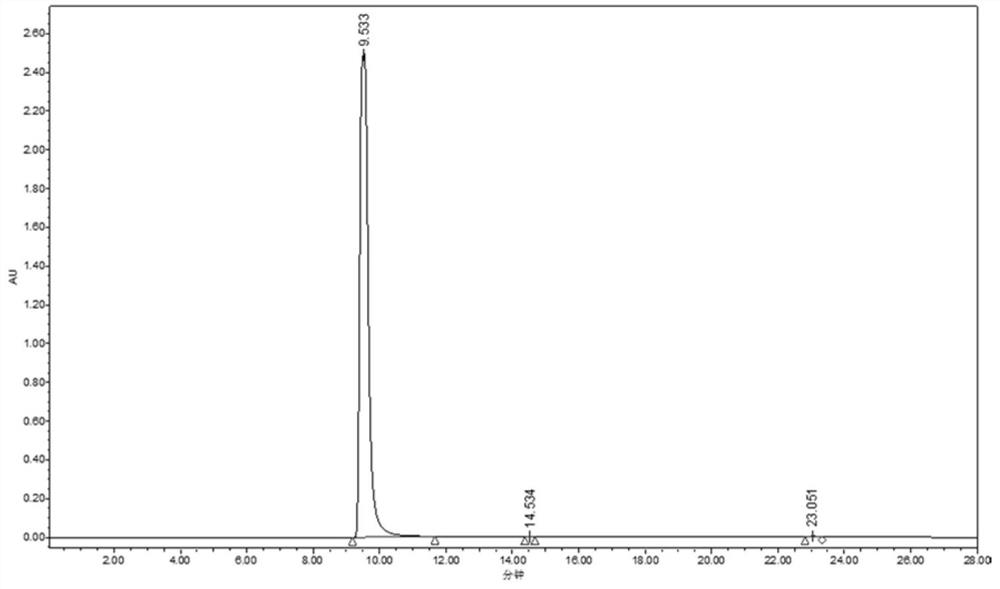

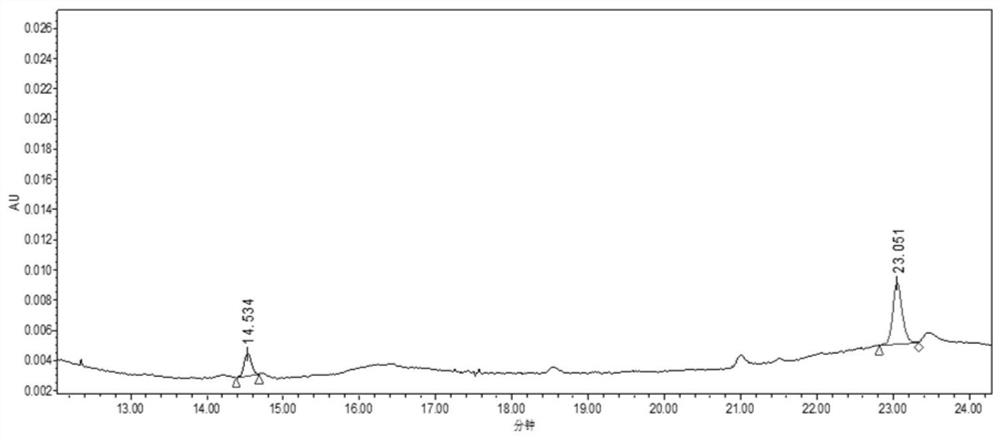

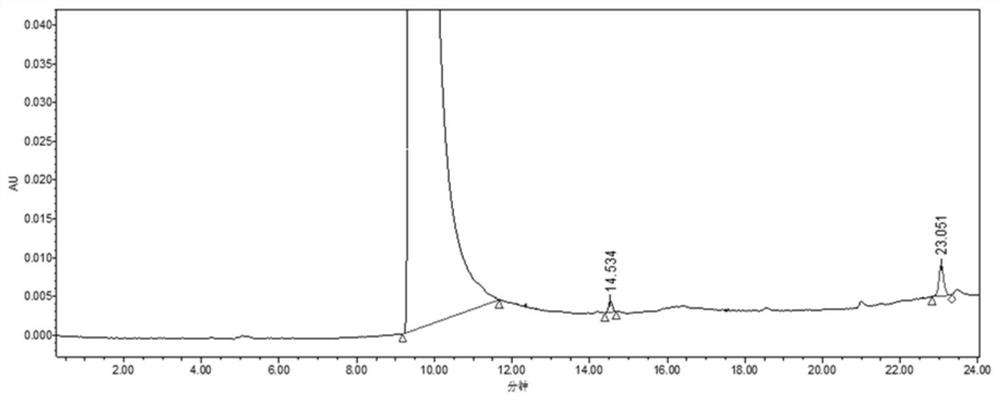

Examples

Embodiment 1

[0024] The purification method of the present embodiment 2-methyl-4-isothiazolin-3-one comprises the following steps:

[0025] (1) Mix 25g of 2-methyl-4-isothiazolin-3-one reagent (purity is 95%, purchased from Aladdin Company) with 10mL acetone (chromatographically pure 99.8%, purchased from Merck Company), and heat up to 40°C, stirred until completely dissolved, kept warm for 10 minutes, and filtered to obtain the mixed solution.

[0026] (2) Place the mixed solution in an environment of 25° C. to cool naturally for 3 hours, and then place it in an environment of 4° C. to cool for 5 hours, and then perform suction filtration to obtain crystals.

[0027] (3) The crystals were washed 3 times with petroleum ether.

[0028] The above steps (1), (2) and (3) are all completed in an inert gas glove box, and the inert gas is nitrogen.

[0029] (4) The washed crystals were subjected to vacuum freeze-drying at a temperature of -80° C., a vacuum degree of <0.12 Mbar, and a drying tim...

Embodiment 2

[0031] The purification method of the present embodiment 2-methyl-4-isothiazolin-3-one comprises the following steps:

[0032] (1) 25g of 2-methyl-4-isothiazolin-3-one reagent (purity is 95%, Bailingwei Technology Co., Ltd.) is mixed with 25mL ethyl acetate (chromatographically pure 99.9%, purchased from Merck Co.), and the temperature is raised to 50°C, stir until completely dissolved, keep warm for 20 minutes, and filter to obtain the mixture.

[0033] (2) Place the mixed solution in an environment of 20° C. to cool naturally for 3 hours, and then place it in an environment of 8° C. to cool for 5 hours, and then perform suction filtration to obtain crystals.

[0034] (3) The crystals were washed 3 times with petroleum ether.

[0035] The above steps (1), (2) and (3) are all completed in an inert gas glove box, and the inert gas is argon.

[0036] (4) The washed crystals were subjected to vacuum freeze-drying at a temperature of -40° C., a vacuum degree of <0.12 Mbar, and a...

Embodiment 3

[0038] The purification method of the present embodiment 2-methyl-4-isothiazolin-3-one comprises the following steps:

[0039] (1) 25g of 2-methyl-4-isothiazolin-3-one reagent (purity is 95%, Bailingwei Technology Co., Ltd.) is mixed with 25mL ethyl acetate (chromatographically pure 99.9%, purchased from Merck Co.), and the temperature is raised to 45°C, stirred until completely dissolved, kept warm for 15 minutes, and filtered to obtain the mixture.

[0040] (2) The mixture was naturally cooled at 23°C for 3 hours, then cooled at 0°C for 5 hours, and suction filtered to obtain crystals.

[0041] (3) The crystals were washed 3 times with petroleum ether.

[0042] The above steps (1), (2) and (3) are all completed in an inert gas glove box, and the inert gas is nitrogen.

[0043] (4) The washed crystals were subjected to vacuum freeze-drying at a temperature of -80° C., a vacuum degree of <0.12 Mbar, and a drying time of 4 days, and finally 21.2 g of snow-white crystals were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com