Bellows seal winding device

A winding device and bellows technology, applied in the field of machinery manufacturing, can solve the problems of low winding efficiency, imperfect winding, unstable quality, etc., and achieve the effects of good sealing effect, high winding precision and controllable winding length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

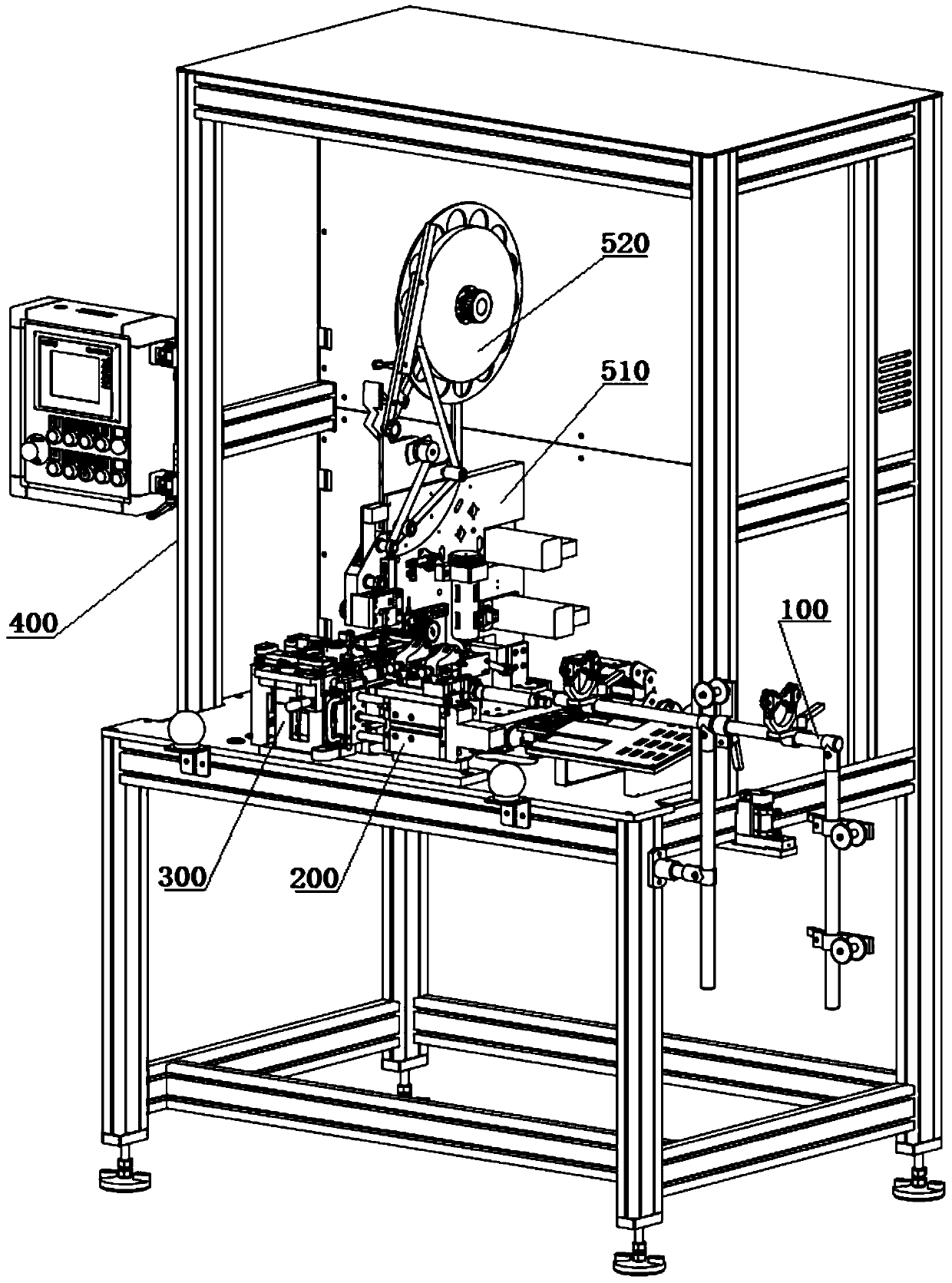

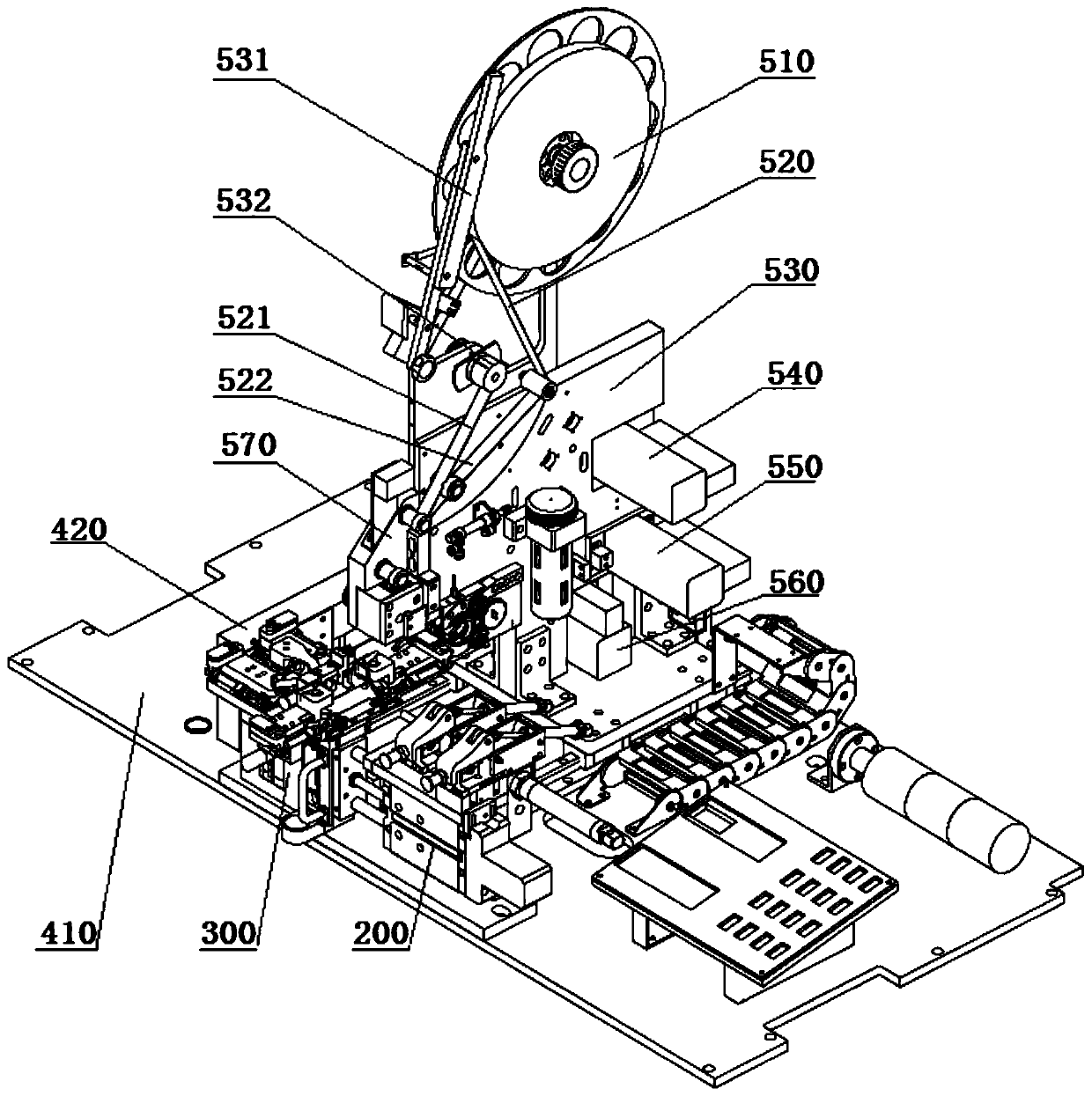

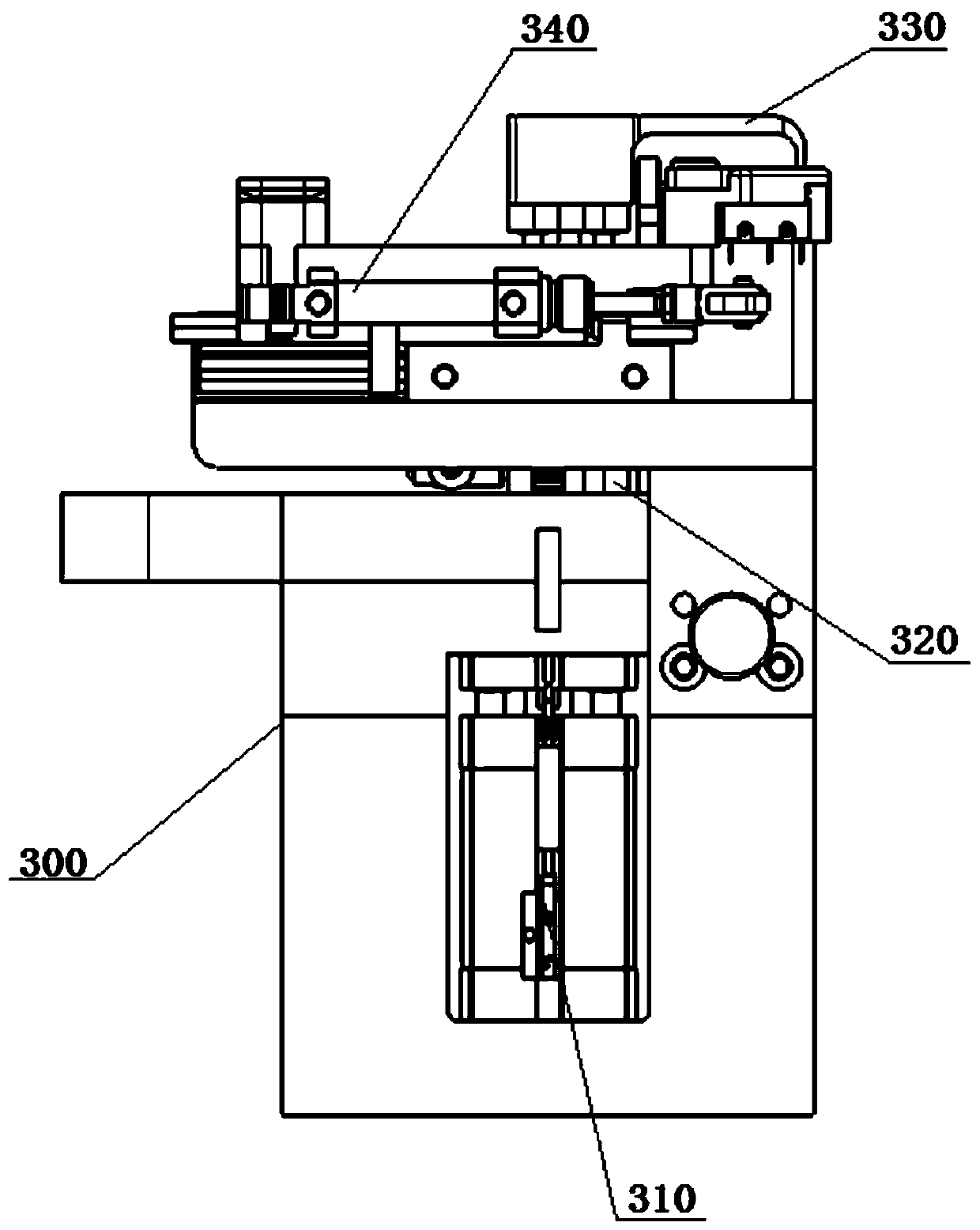

[0058] Such as Figure 1-9 As shown, the present invention provides a bellows sealing and winding device, including: a frame body 400 and a sealing device assembly arranged inside it, and the sealing device assembly specifically includes: an operation table 410, a long tube storage mechanism 100, a stretched bellows Assembly 200, pressure head fixture assembly 300 and sealing mechanism.

[0059] Such as figure 1 As shown on the console 410, it is provided with a long tube storage mechanism 100, a stretch bellows assembly 200, and a pressure head fixture assembly 300 in sequence from right to left. The sealing mechanism is arranged on the console and can be vertically direction to slide back and forth so that it approaches and moves away from the indenter clamp assembly 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com