A vacuum bottle packaging equipment

A technology of packaging equipment and vacuum bottles, which is applied in the direction of pressurized/vaporized packaging, can solve problems such as insufficient technical considerations, shortened food storage time, and accelerated food deterioration, so as to prolong storage time, ensure vacuum degree, and improve The effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

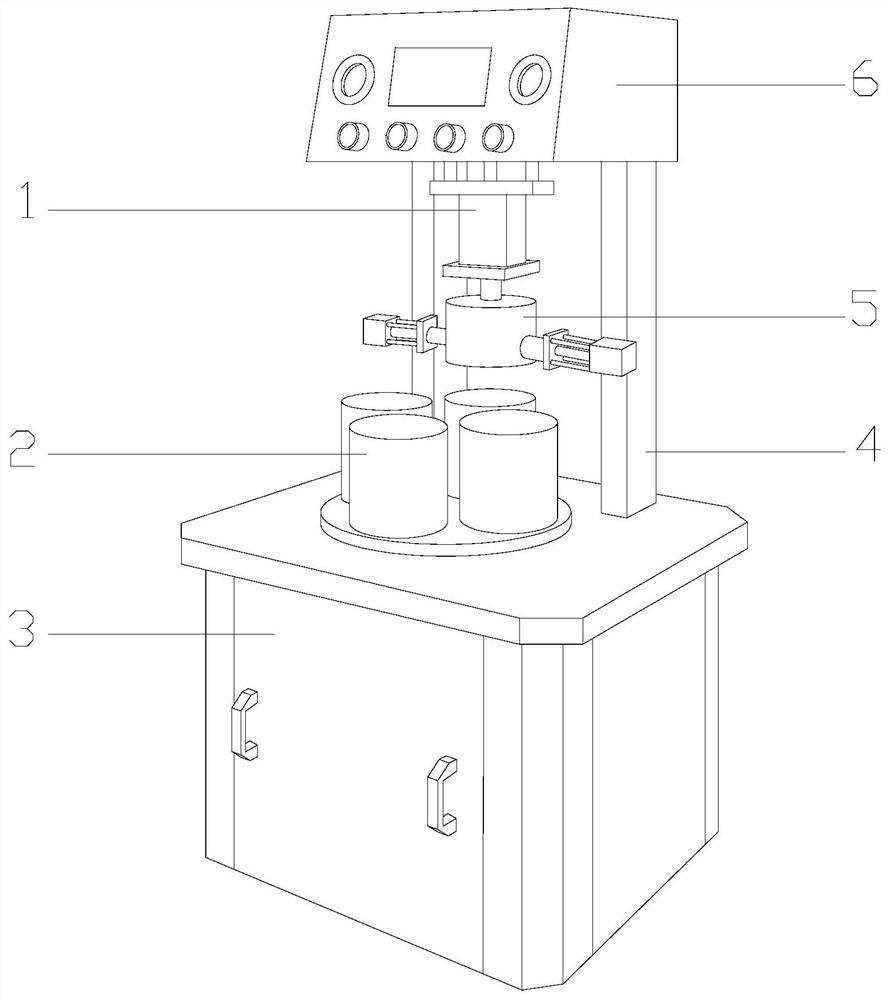

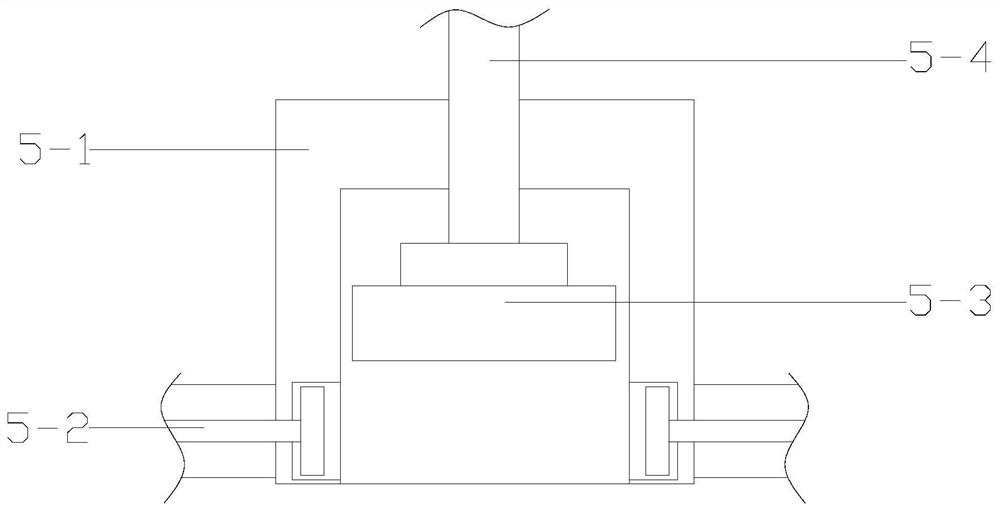

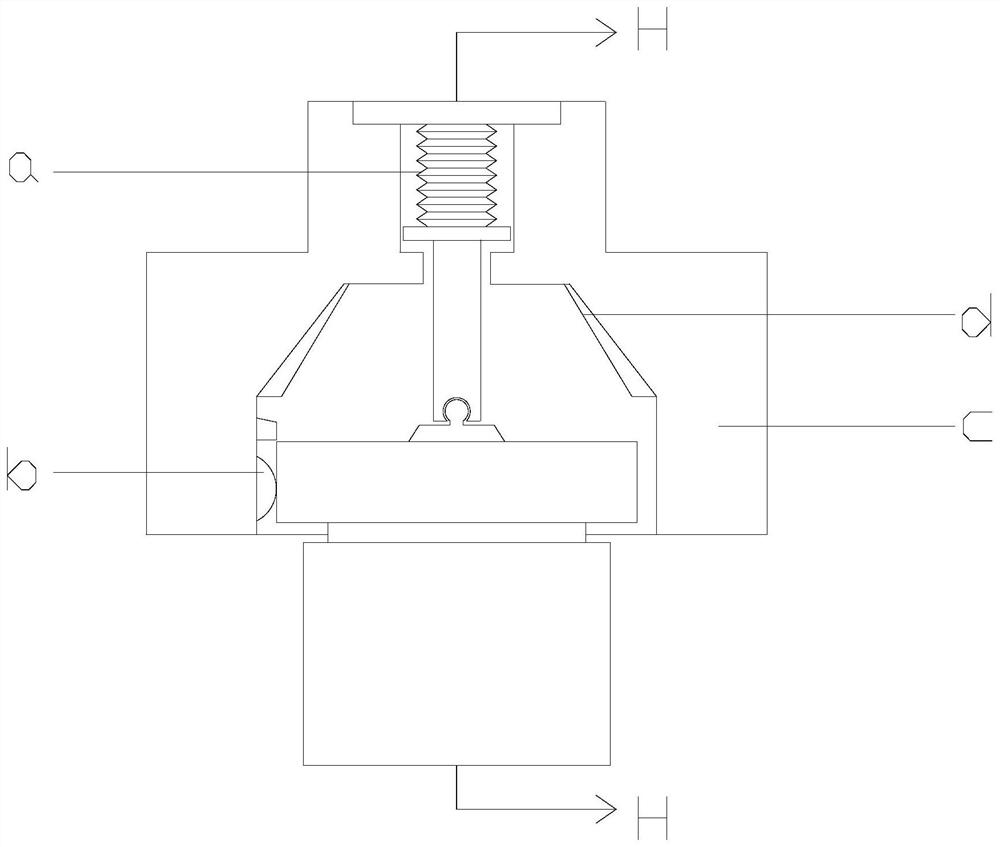

[0027] see Figure 1-Figure 2 , the present invention provides a vacuum bottle and can packaging equipment, the structure of which includes a telescopic cylinder 1, a jar fixing seat 2, an equipment support platform 3, a connecting frame 4, a vacuum screw cap structure 5, and a packaging machine controller 6. The equipment support platform 3, the bottom surface is close to the ground, the tank fixing seat 2 is nested in the middle of the upper surface of the equipment support platform 3, the bottom of the connecting frame 4 is interlocked with the equipment support platform 3 and is perpendicular to the equipment support platform 3, so The bottom surface of the packaging machine controller 6 and the top of the connecting frame 4 are fixed together by bolts, the top of the telescopic cylinder 1 is close to the bottom surface of the packaging machine controller 6 and is electrically connected, and the top of the vacuum screw cap structure 5 is connected to the telescopic The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com