Light aircraft flap manipulation device

A control device and light aircraft technology, applied in the field of general aviation, can solve the problems of increased failure rate of flap system, complicated principle, and increased aircraft power load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

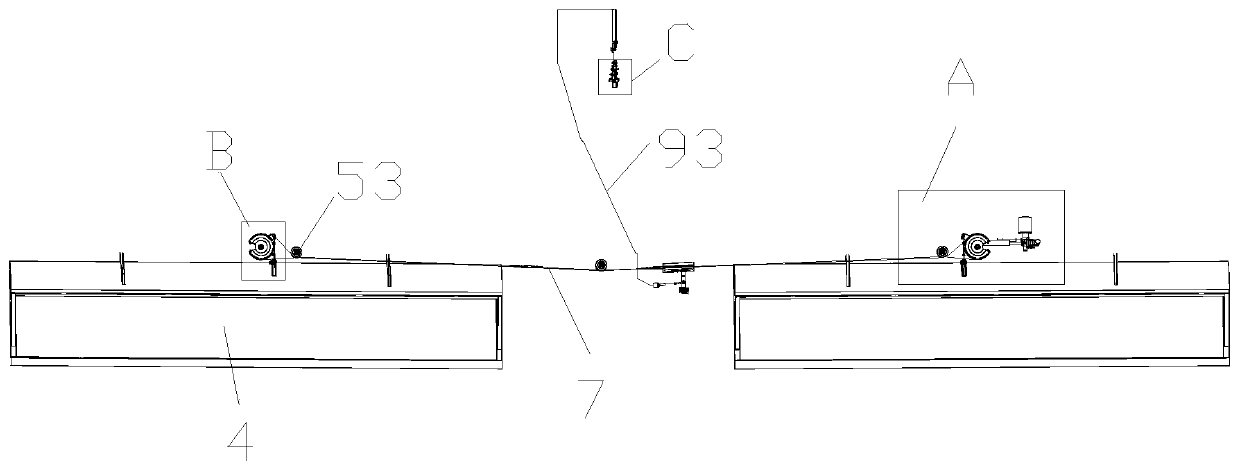

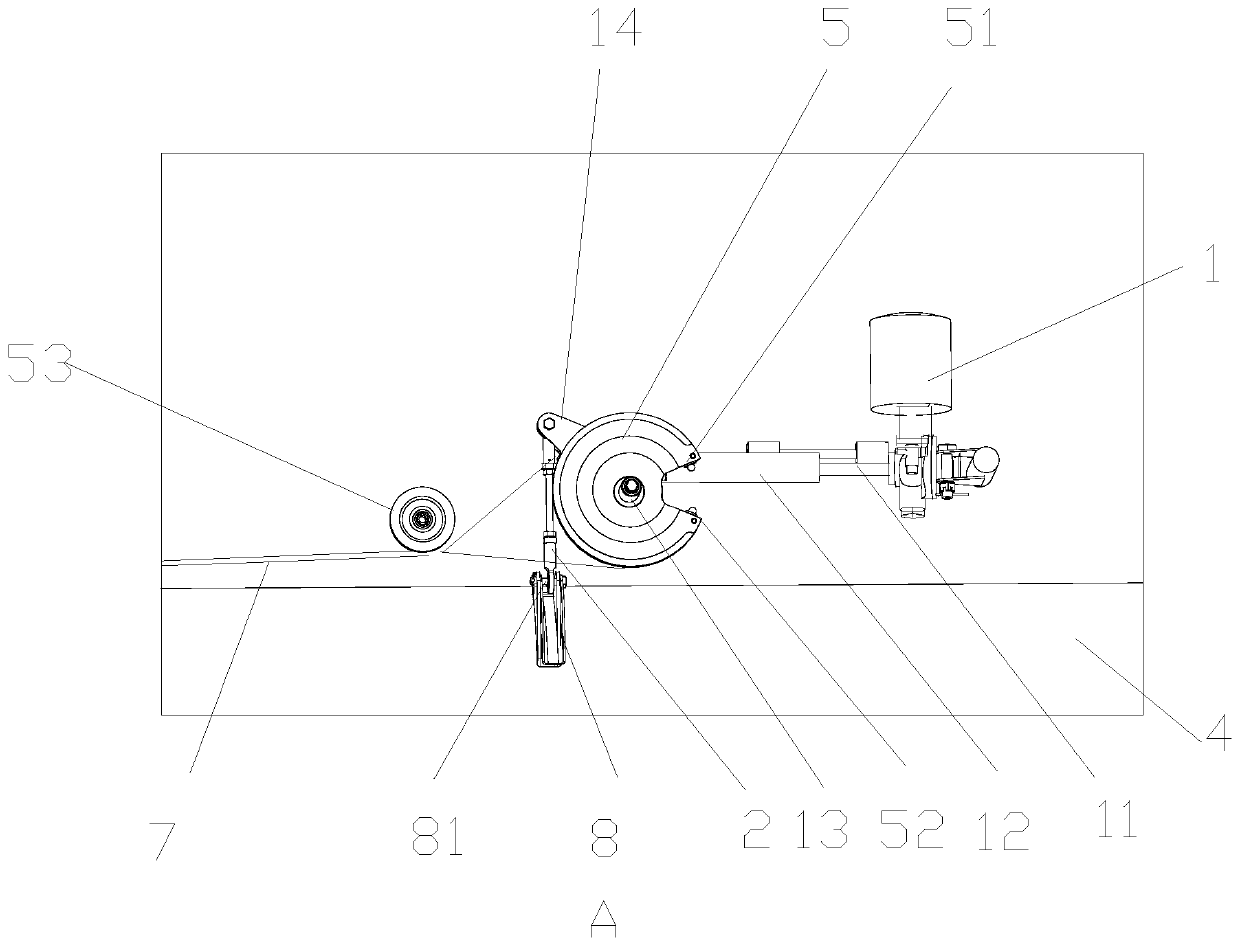

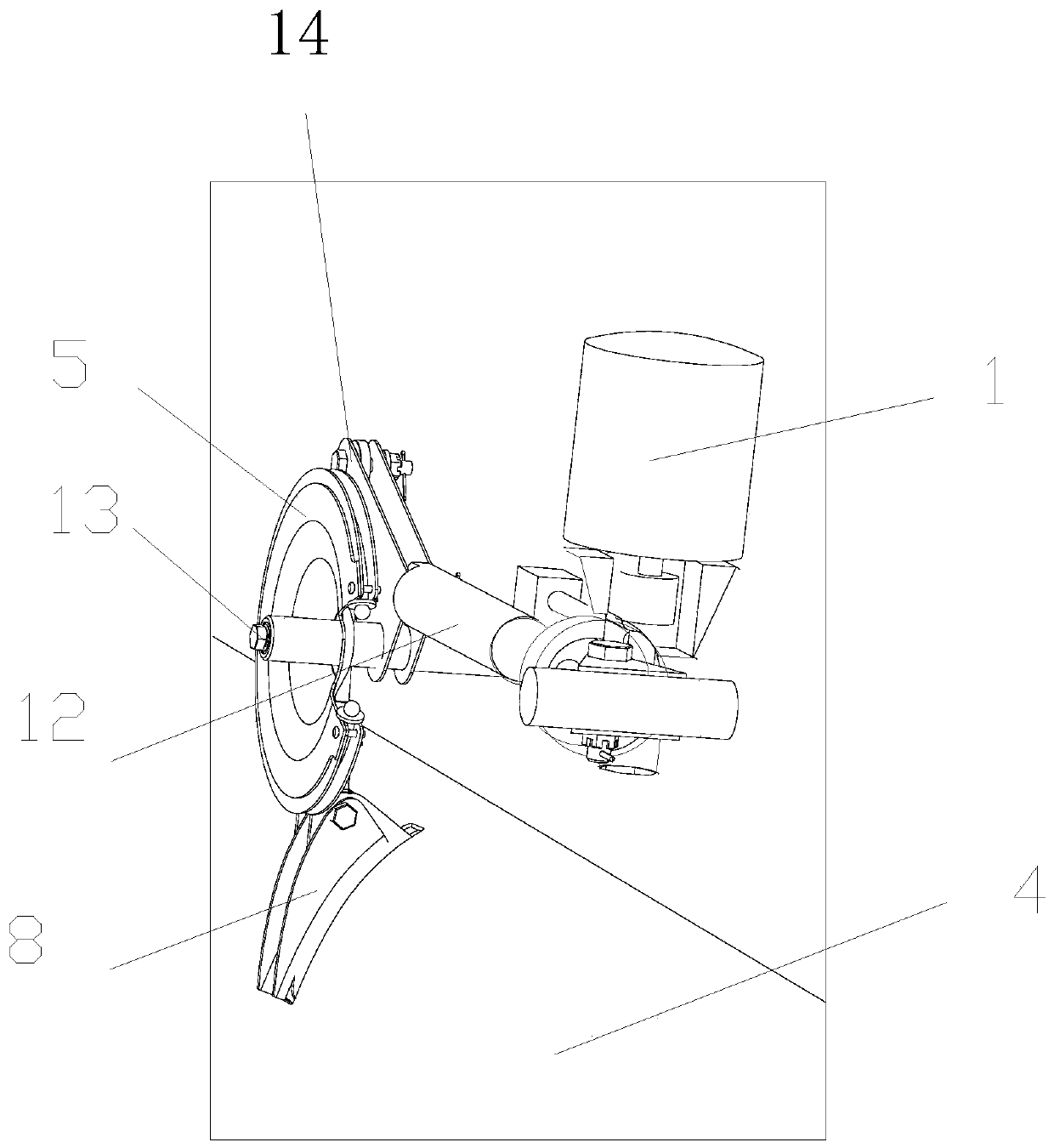

[0033] Attached below Figure 1-7 The present invention is described in further detail.

[0034] A light-duty aircraft flap control device, comprising a flap control handle mechanism, a flap driving mechanism, a flap linkage mechanism and a feedback mechanism, the flap driving mechanism includes a motor 1, the output shaft of the motor 1 is fixedly connected with a worm 11. The outer side of the worm 11 is screwed with a worm shaft cylinder 12, the end of the worm shaft cylinder 12 is hinged with a triangular piece 14, and one end of the triangular piece 14 is fixedly connected with the first rotating shaft 13; the flap linkage mechanism includes a second A pull rod 2 and a second pull rod 3, the first pull rod 2 and the second pull rod 3 are respectively hingedly arranged at the rotation positions of the two flaps 4, the upper end of the first pull rod 2 is hinged with one end of the triangle piece 12, and the first pull rod 2 is hinged with one end of the triangle piece 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com