Tray hole piercing and guiding device and guide hole permeable brick preparation method

A technology of permeable bricks and guide holes, applied in the direction of forming indenters, molds, ceramic forming cores, etc., can solve the problems of groundwater level drop, heat island effect, groundwater cannot be replenished in time, etc., and achieve good hole-forming effect and simple device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

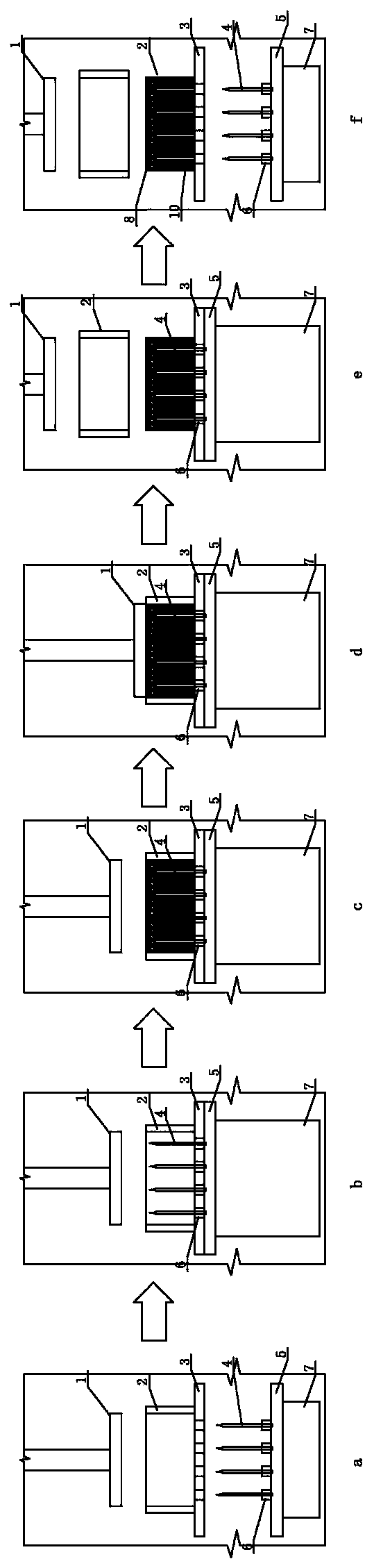

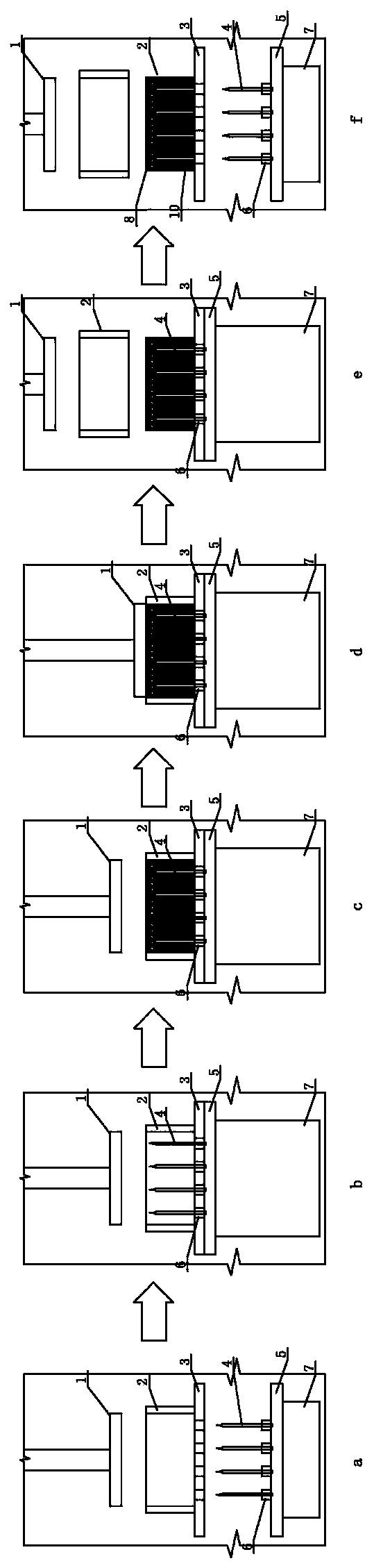

[0025] 1. A tray perforation guide device and a method for preparing a guide hole permeable brick. The guide device is installed under the brick machine, and the tray carrying the permeable brick is pre-punched under the mold of the brick machine; the lifting system of the guide device rises to make the guide hole The hole needles pass through the tray, and the material is placed twice and once compacted to form a permeable brick. The lifting device drives the chassis down, and the guide needle is pulled out from the permeable brick, forming a guide hole in the structural layer. brick.

[0026] 2. Pallet modification: The pallet needs to be modified before the permeable brick is prepared. According to the distribution of the guide needles on the guide hole device, the tray is pre-punched, and the diameter of the holes is 3 to 4 times the diameter of the guide needles, which is convenient for the guide needles to pass through the holes to make holes.

[0027] 3. The hole guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com