Full-automatic rotating type cinnamon peeling machine

A technology for peeling knives and green bark, which is applied to bark, grinding drive devices, and parts of grinding machine tools, etc. It can solve the problems of inability to realize automatic feeding, dangerous operation, low efficiency, etc., and achieve the effect of improving peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

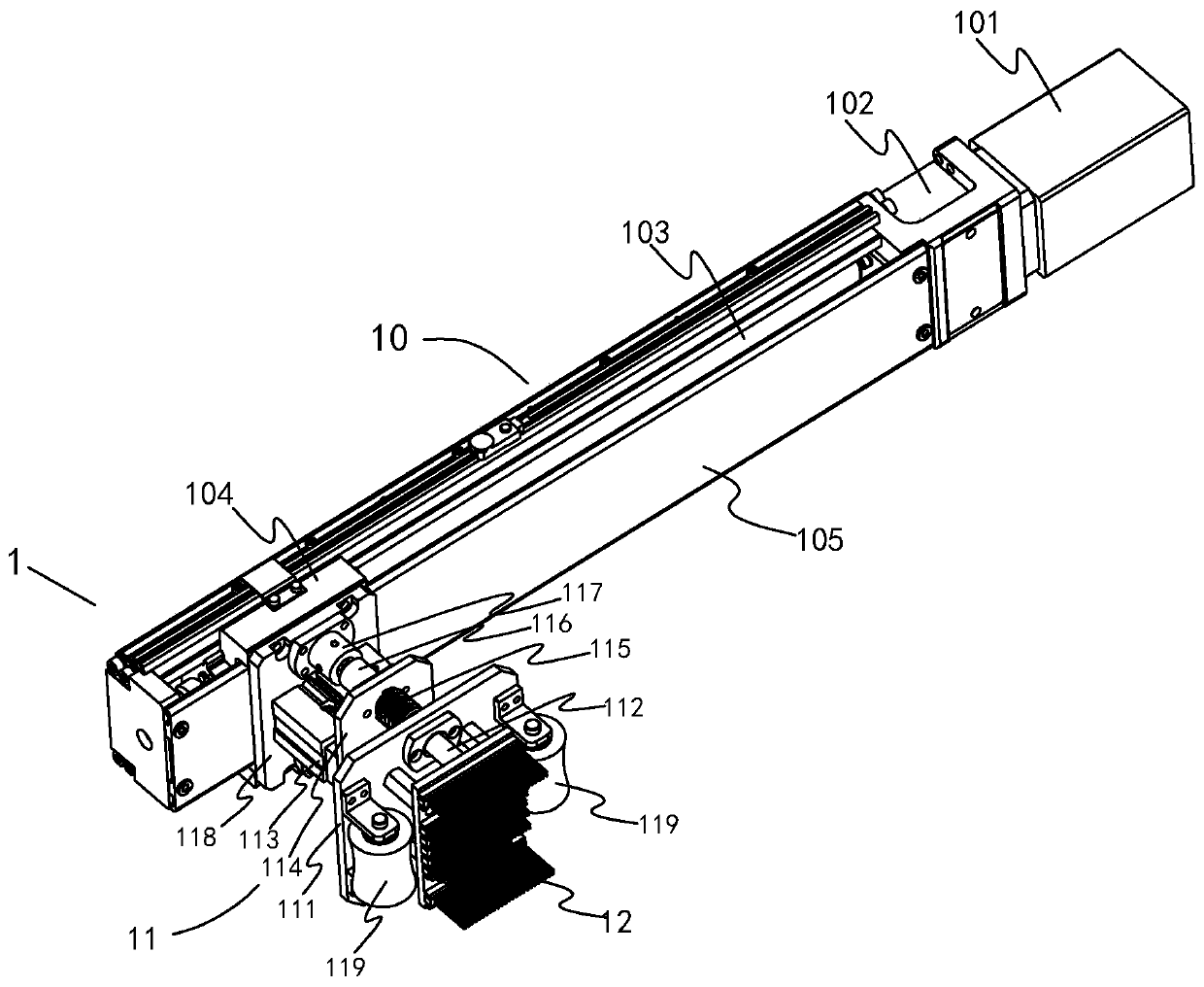

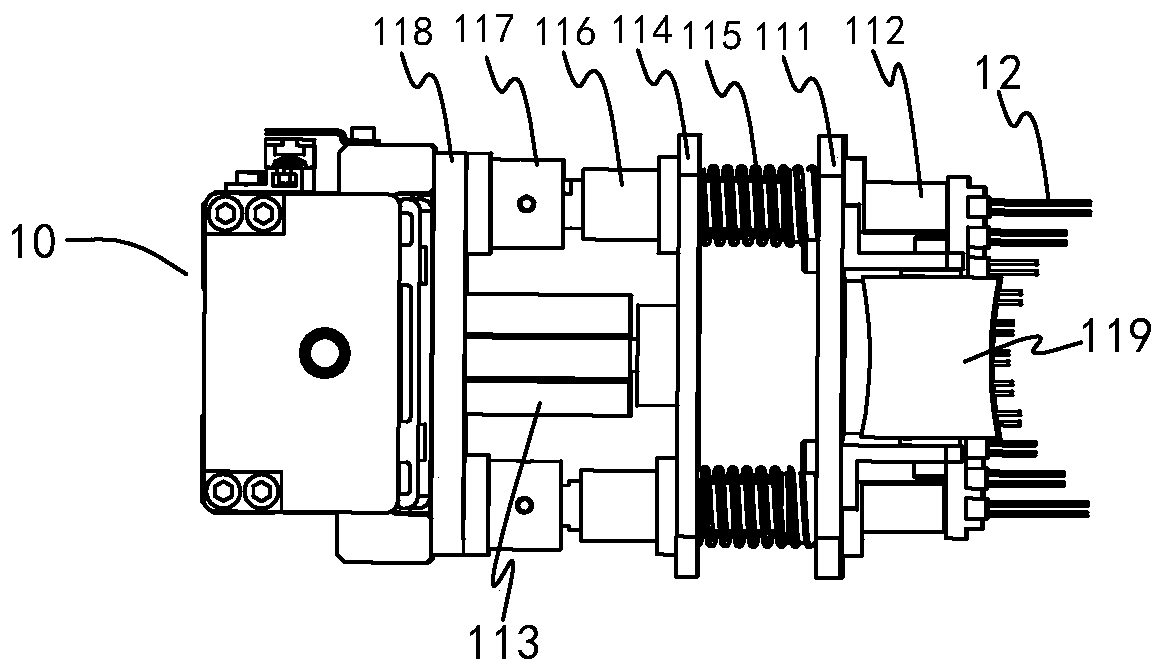

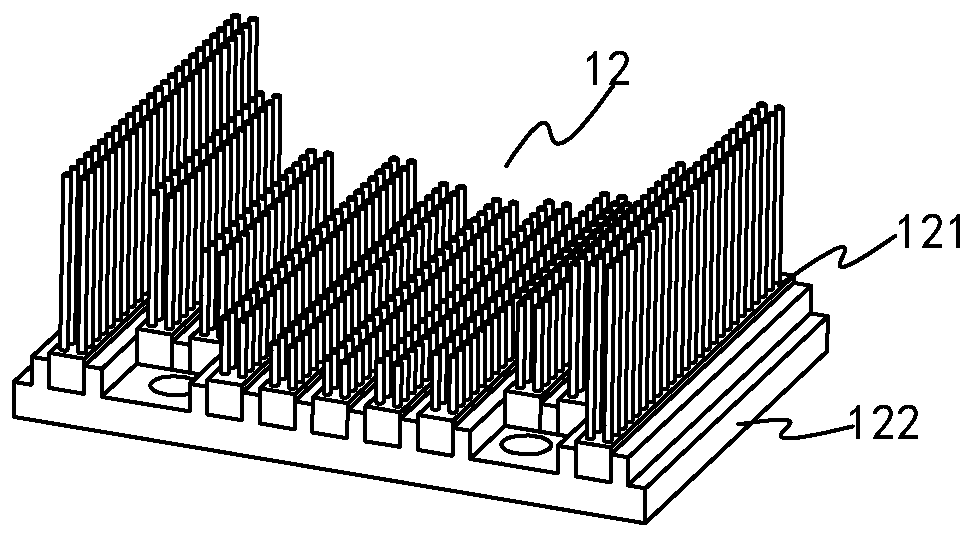

[0032] The peeling device provided in the embodiment includes a feeding mechanism 3, a peeling mechanism 1 and a peeling mechanism 2, and the feeding mechanism 3 is used to clamp the tree segment to be peeled and transported to the green peeling mechanism 1 and the peeling mechanism 2 successively for processing, so as to realize automatic Remove green skin and peel. Taking the cinnamon tree as an example, the branches of the cinnamon tree with a diameter ranging from 50mm to 100mm are removed, and the length is about 380mm (the length just required by the market) is cut into a section to obtain the tree section to be peeled. When the cinnamon tree grows, there is a thin layer of green skin on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com